What is Tremie Pipe?

Important Point

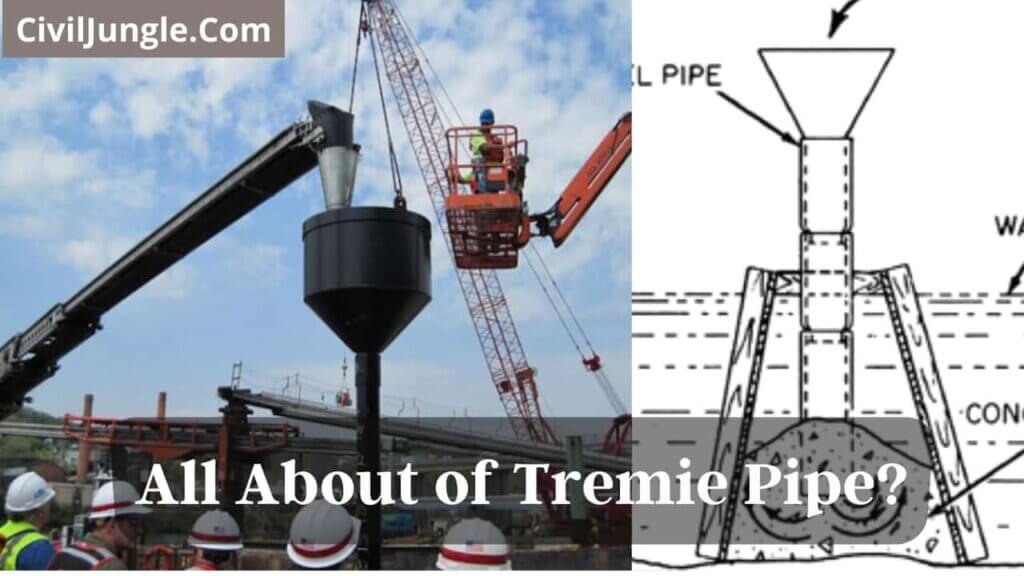

A tremie is a pipe that can use for pouring concrete underwater. Its standard function is in basements, diaphragm walls, piling works, caissons, and underwater foundations. The time pipe length is 300mm, made of plastic tubes.

A tremie pipe uses to concentrate underwater in a way that concrete is quelling slowly. This procedure will not give an acceptable solution as a particular quantity of washing away of cement is skip to happen.

A dry mixture of cement decent and rough sum is complete in cement bags and, like bagged concrete, is fixed on the bed under the water. This procedure does not provide acceptable concrete, as the concrete mass cover of clear disperse with the short-lived gunny bags. Tremie pipe procedure of concrete pouring underwater is a proper procedure that spreads worldwide.

Also, read: Testing for Silt Content in Sand

Underwater Concrete Mixes

- Cement: ASTM, Type II, 600 lbs. / yd3.

- Coarse aggregate: gravel of 3/4″ max. Length. The total sum by weight is 50-55%.

- Fine aggregate: sand is 45-50% of the total weight of aggregate.

- Pozzolana: ASTM 616 type N or F, 100lbs/yd3.

Underwater Concrete

- Water-cementitious ratio: o.35 to 0.45 by mass

- Fines content: 360 to 500kg/m3

- Water-to-fines ratio: 0.85 to 1.0 by volume

- Sand-to-total content ratio: 45% to 50%.

- Setting time : 5-24 hours

- Slump: 6 ½ inches. +- 1 inch.

Tremie Method of Underwater Concrete

- Underwater concreting using the tremie method is suitable for draining a high quantity of heavy leakage concrete.

- The concrete is displaced to the hopper by further pumping, belt skips.

- Tremie pipe, the top ending jointed to a hoper and bottom ending running drowned in new concrete, is used to locate concrete at the correct position from the hopper at the field.

- The cause to dip the tremie pipe bottom end is to stop combine of both concrete and water.

- Because of mass size, Tremie pipe should have a capable diameter to block the leakage.

- Commonly diameter is 200-300mm aggregate of clear junction for up and down of size.

- The lower end is secured with a plug and chosen below.

- The water keeps the peace at the location where the concrete is running. Later the end is close, and no water will have passed the pipe.

- The concrete must have a 15-20cm slump to dig into the funnel when the total size of the tube covering with concrete, the tremie pipe boost, and a slight jerk given by a tackle and pulley.

- When the line heaves and provides a draw, the lower plug falls because of a load of concrete, and concrete gets released.

- Must take particular heed to this situation to look which the end.

- Tremie pipe continues in the concrete so that no water passes the line from the lower.

- Again concrete is dug over the funnel, and when the total size of the tremie pipe cover with concrete, the tube is again slight boost and given a small jerk.

- Care choose every time to keep the bottom end of the tremie pipe in raised concrete. The concrete of the tremie pipe gets released in that time.

- This process carried out smoothly benefits the concrete does not get damaged by the water omitting the upper end.

- The upper layer is purified to take off the damaged concrete at the end of the entire function.

Also, read: What Is Plinth | What Is Plinth Protection | Purpose of Plinth Protection

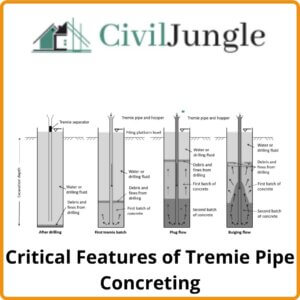

Critical Features of Tremie Pipe Concreting

- At the time of the concrete process, no pumping of water should be allowed; the cement piece, if jointly pumping of water is done.

- Next, the concrete is appropriate, which does not usually need compression.

- The main demerit of underwater concreting is in this process in that a more water ratio needs more consistency which decreases the power of concrete.

- On the other hand, the cementing method of wrapped aggregate is not so usually occupied to location concrete below water.

- The prepared cement mortar cementing is fitted by the pipe, which spreads to the lower aggregate bed.

- The grout power the water out from the gap and employs the place.

- Concrete can locate underwater by the use of pipes and concrete pumps.

- When the whole pipe is covered, the plug eject; the concrete near the bottom end of the line secures the tube.

- The pumping is opposed to the plug’s mass at the bottom end. When the pumping issue need is too high to pass the pressure, the pipe eject, and the process is regular. This method continues since the concrete arrives at a level above water.

Tremie Pipe

A tremie is a watertight pipe, usually of about 250 mm inside diameter (150 to 300 mm), with a conical hopper at its upper end above the water level. It may have a loose plug or a valve at the bottom end.

Tremie Concrete

A tremie is used to pour concrete underwater in a way that avoids washout of cement from the mix due to turbulent water contact with the concrete while it is flowing. This produces a more reliable strength of the product.

Concrete Pump Tremie Hose

The pool of concrete is allowed to build inside the form raising its elevation. And forcing the water out of the top of the form kerry is required to slowly retract the pump line as the form fills.

Concrete Tilt Wall

Tilt-up concrete gets its name from the manner in which construction occurs: by lifting or tilting panels with a crane to form the walls of buildings. Panels can be produced in many shapes and sizes, including flat and curved sections. Concrete placement is fast and easy because it is done on the ground.

Tension Foundation Slab

A post tension slab is a concrete slab with steel cables running through it that have been placed under 33,000 +/- pounds of tension. This tension makes the concrete slab and foundation much stronger than concrete without reinforcement and helps reduce cracking.

Pier Footing Foundation

Piers and footings are terms used to describe parts of the concrete foundation built under a structure to support the weight of the building. When a home, commercial building or deck is constructed, the structure must rest on a concrete foundation to prevent the weight of the building from causing the ground to shift.

Structural Concrete Repair Contractors

To use epoxy injection to repair a crack, the crack is first cleaned by vacuuming or flushing with water to get out any dirt or contamination. The cracks on the surface are then sealed with an epoxy gel to prevent the injected epoxy from running out.

Block and Pier Foundation

A full block foundation consists of concrete block, mortar and reinforcement. The block is laid to form a wall around the perimeter of the home. A “pier and curtain” foundation consists of concrete block, mortar and brick. Concrete block piers are built every 6 to 8 feet providing support for your home.

Concrete Wall Repair Contractors

- Step 1: Scrub it clean.

- Step 2: Use a nail to align injection points.

- Step 3: Mix the two-part epoxy crack sealer.

- Step 4: Spread the sealer onto the base.

- Step 5: Mix and apply a larger batch of epoxy sealer.

- Step 6: Dispense the lcr epoxy.

- Step 7: Fill up the ports.

Underwater Concrete

Underwater concrete anti-washout admixtures are water-soluble organic polymers which increase the cohesion of the concrete in a way that significantly reduces the washing out of the finer particles, i.e. cementitious material and sand from fresh concrete when it is placed underwater.

What Is Tremie Method of Concreting?

A tremie is used to pour concrete underwater in a way that avoids washout of cement from the mix due to turbulent water contact with the concrete while it is flowing. This produces a more reliable strength of the product.

Tremie Concrete

Tremie concrete refers to placement by gravity feed from a hopper through a vertical pipe extending for above the surface to the underwater floor. As concrete flows from the bottom of the pipe, more is added to the hopper so that the tremie pipe is continuously charged with fresh mix. The major aim in underwater concreting is to place the mix in its final position with as little disturbance as possible.

Tremie Method

Tremie method is one of the most common methods that is used for concreting under water. In this method, a long steel pipe (named as tremie) having a diameter of 15 to 30 cm is inserted vertically into the water.

Concrete Tubes

The Sonotube Concrete Form Tubes are made of lightweight material designed for pouring footings, round columns and piers. It is an inexpensive option that saves time and provides professional results.

Underwater Cement

Portland cement is a hydraulic cement that sets and hardens in the presence of water. Concrete made with Portland cement will harden even if it is completely underwater.

House Concrete

The concrete is moved to the hopper by either pumping, belt conveyer or skips. Tremie pipe, which upper end connected to a hopper and lower end continuously submerged in fresh concrete, is used to place concrete at the exact location from a hopper at the surface.

Pipe Process

A pipe usually connects only two processes, although any number of child processes can be connected to each other and their related parent by a single pipe. A pipe is created in the process that becomes the parent by a call to pipe(2). The call returns two file descriptors in the array passed to it.

Underwater Pipes

Undersea pipes are mostly used to move oil and gas. Companies mine both from the ocean floor and the pipes are used to bring these fossil fuels ashore. After oil or gas has been refined, different pipelines are used to move oil, or the liquefied natural gas, to fuel tankers.

Like this post? Share it with your friends!

Suggested Read –

- West Point Bridge Designer

- Difference Between 33, 43 and 53 Grade Cement

- Difference Between One Way Slab and Two Way Slab | What is Slab

- Introduction of USCS | USCS Classifies Soils into Two Broad Categories

- What Is a Field Dry Density Test | Different Type of Field Density Tests

- What Is Slump Cone Test | Principle of Slump Test | Types of Concrete Slump

- What Is Plaster | Plaster Ratio | History of Plastering | Requirements of Good Plaster

- Introduction of Gantry Girder | Load on Gantry Gutter | Type of Load on Gantry Gutter

- Dog-Legged Staircase | What Is Staircase | Advantages & Disadvantage of Dog-Legged Staircase

- What Is Chicken Mesh for Plaster | Type of Chicken Mesh for Plaster | Why Use Chicken Mesh for Plaster

Originally posted 2022-04-22 17:15:50.

Leave a Reply