What Is Wood Pulp?

Important Point

Wood pulp is a kind of material that is lignocellulosic fibrous in nature. It is produced by separation of wood from cellulose fibers.

It is made from the relegating of fibrous part of primarily trees, plants, and is the essential ingredient in the process of paper making.

To produce paper, pulp is most used for all sorts of products. Wood pulp can be found in napkins, cups, toilet paper, newspaper and in any of the paper products.

Two ways can be used for the product to be produced, i.e., mechanically, or chemically.

Wood is made to transfer into pulp which leads to the formation of lignin, wood fiber, and water.

The chemical by-products can also be made to left behind if chemicals were made to use during the manufacturing process.

Wood is currently the most widely used material to produce pulp.

The mechanical pulping process will involve grinding of wooden chips into a mixture of lots of lignin and small number of cellulose fibres.

This method results to the formation of weak-quality paper.

This kind of paper will be best suitable for thin kind of products such as newspapers.

Chemical pulping which is also referred as kraft process, this is the most ubiquitous method that is used to produce wood pulp.

After the turning of raw wood into “kraft pulp,” chemicals are used for the separation of cellulose fibres and lignin.

The raw cellulose fibers hence produced can be used for the manufacture of stronger paper.

The most common chemicals to be used in pulping are limestone and sulfurous acid which will create calcium bisulfide when commingled.

After the cooking of wooden chips with the sulfite process, lignin gets dissolved, and gets raw cellulose fibers left behind.

Along with wood, materials like bamboo, straw, flax, hemp, cotton, etc., are used by companies for the process of pulp making.

Also Read: How to Get Wood for Free?

Components of Wood Pulp

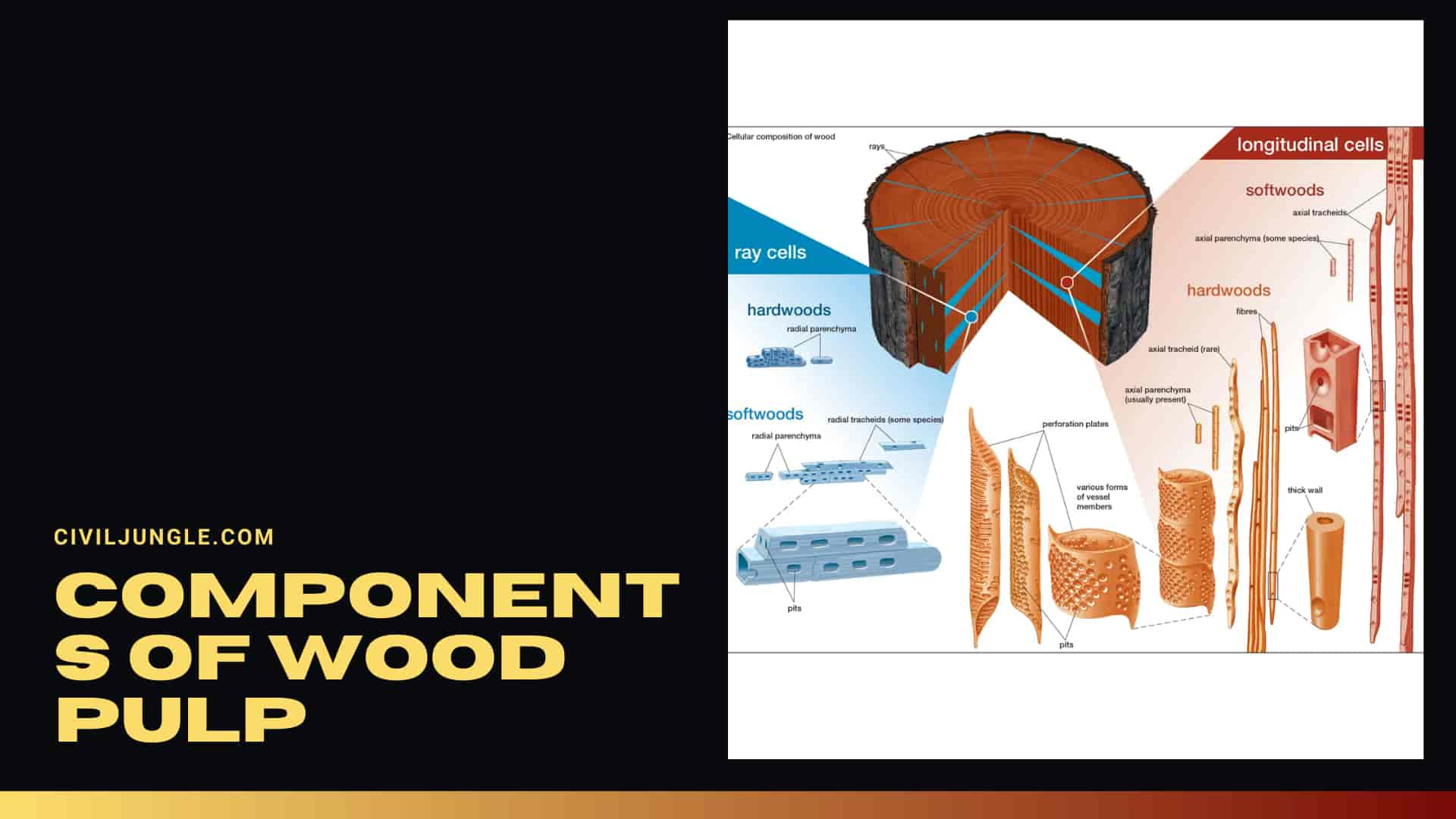

Woods principal components consist of cellulose, hemicellulose, extractives, and lignin.

Cellulose is nothing but a huge chain of carbohydrates having a repeated unit of glucose or sugar.

Hemicellulose consists of short-chained carbohydrates consisting of five different varieties of sugar, which will be acting as building blocks.

Different species of wood will have varied amounts as well as types of these ingredients.

This will mean that all kinds of wood will not be making similar quality of paper.

Chemically produced wood pulp consists of wood and various chemicals such as sulfite, sulfate (soda), and soda processes.

Mechanically produced wood pulp consists of ground wood and mechanical chip pulping having high residual lignin or glue content.

Recovery-produced wood pulp consist of pulp made from recycled paper combined with water which consists of newspapers, magazines etc.

This type will contain combined form of different pulps.

Also, Read: How to Get Free Land in US?

Hardwood and Softwood Pulp

The properties of pulp are dependent on a wide range of factors, which are age, species, density, moisture content, etc.

Generally, each species is classified by scientists into two primary categories or families, i.e., softwoods and hardwoods.

Hardwoods are leafed, deciduous where as softwoods are needle-bearing conifers.

On the contrary, softwoods have higher amount of lignin than hardwoods.

On an average, for the purpose of pulp softwood fibers have three times the length of hardwoods.

It is to be remembered that, in crease in the length is directly proportional to an improved inter-fiber bonding, it means that softwood pulp will offer more strength than hardwood.

For example, bleached softwood Kraft will be more durable in nature and offer higher strength than that of bleached hardwood Kraft.

Also, Read: How to Get House for Free

Different Trees Produce Different Pulp

The type of wood and species helps in determining the properties and quality of the pulp.

This helps in determining what type of product can be made from the pulp made.

Like for example, softwood will produce a very different pulp as compared to hardwood, at the same time the respective pulps produced are used for making much-differentiated end products.

Conifers like spruce and pine are softwood trees. They consist of long fibers having a quite low density.

Long fibers help in providing strength to them, that is the reason softwood pulp can be used for the creation of strong products.

Softwood pulp also helps in the increase of absorbency which in turn helps in making great to produce toilet paper, paper towels, diapers, and many other hygiene products.

Leafy trees are generally considered to be as hardwood. This type has a short length which in-turn makes the pulp to be soft.

This is the reason; hardwood pulp is generally used for the making of tissue papers.

A blending is done between hardwood and softwood which is done at different proportions, as a result the end products are altered.

It can be assumed as a recipe that helps in adjusting the paper quality that is being made.

If little more absorbency is required then you can add more pulp from softwood trees. While if a little bit of softness is required, you can add more pulp from a hardwood tree.

In the industry of paper and pulp, softwood pulp is treasured for their strength. This is the reason they are used for the manufacture of packaging papers and boxes.

A very soft pulp is created by eucalyptus wood which is quite great for the manufacture of soft tissue paper.

Each tree helps in the production of different types of wood pulp having different properties.

The pulps then formed can be mixed properly together, just like a recipe, which is done for the alteration of paper product being made by you.

Also Read: Heartwood Vs Sapwood

Conversion of Wood into Pulp

In the previous times, companies generally carried out two distinct pulp making procedures: chemical and mechanical.

Thanks, should be given to advanced technology, companies can combine several aspects of both methods.

Basically, the pulping processes consist of the following categories:

1. Mechanical Pulps

These kinds of pulps are generally quite effective in nature, because it consists of 95% of the original wood components.

The products manufactured from mechanical pulps consist of higher percentage of wood components, which in-turn helps in offering an economic advantage.

While, this process might cause unavoidable damage to the wood. Due to this, the pulp that is produced consist of lower strength.

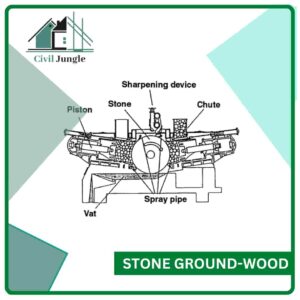

2. Stone Ground-Wood

This process is another important way that consists of forced debarked logs against a hefty abrasive stone.

The stone helps in shredding of fibers from the wooden material.

After that, the staff will carry out the process of screening for the removal of oversized slivers or shivers and other components that are not required to be present on the wood.

Bleaching is also carried out by some companies in order to make the pulp appear bright.

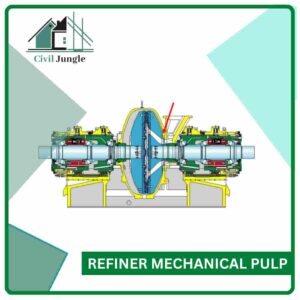

3. Refiner Mechanical Pulp

Wooden chips are used by refiner mechanical pulp as one its primary input.

Large metal discs are used by companies in the refiner machinery for the making of this kind of pulp.

This process will involve the separation of fibers from the wood and production of mixture having a longer length than that of ground wood pulp.

It is to beard in mind that refiner mechanical pulp generally consists of a lower portion of small fibrous pieces.

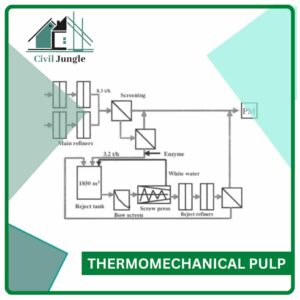

4. Thermomechanical Pulp

This type of pulp is made to produce with the help of a unique process that involves softening of the wooden chips with the help of steam before it is entered to a pressurized refiner.

The reason for doing so, is to separate the cellulose mechanically, hence help in reducing the risk of any kind of damage to any individual piece of fibre.

Due to this reason, the pulp that is produced is more cogent than that of stone ground wood and refiner mechanical pulp.

The problem is that, this process will utilize an immense amount of energy for the job to be done.

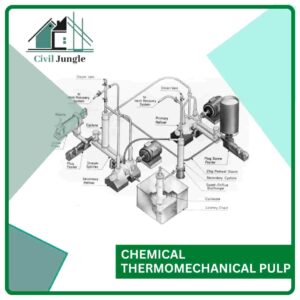

5. Chemical Thermomechanical Pulp

This process is an advanced procedure that will involve treatment of wooden chips before the heating of fibers is carried out.

This process will produce pulp that has strong physical properties.

Different parameters are altered by companies, that includes chemical concentration, chip length, temperature, etc., for customizing the output.

This is the reason; the chemical thermomechanical pulp can be made to use a broad range of applications.

Also, Read: What Is a Cold Joint in Concrete

What Kind of Products Are Made from Wood Pulp?

The base material used to produce all other paper products is pulp.

Any kind of paper products that is used by you has started out as wood pulp.

Writing or print paper, paper towels, dishes, cups, craft paper, cardboard, boxes, and very much everything that can be imagined as a paper product is made of wood pulp.

Varieties of other items that are used by us every day will surely contain wood pulp.

Fluff pulp can easily be used for making absorbent and personal care items such as diapers and any kind of personal hygiene products since it is very well capable of absorbing liquids.

In a solvent dissolving pulp can be dissolved and then make it into textile fibers like rayon or Lyocell.

The spun fibers hence produced are then made to use for the making of shiny clothes.

You would be surprised to know that wood pulp can also be used in a variety of our daily products, as well as other products such as toothpaste as filler.

Also, Read: How Many Stairs Are in a Flight

Green Pulp Making

Cooking of wooden chips is involved in chemical processing along with chemicals under very high pressure.

This helps in the removal of lignin from the wood and helps in its separation into cellulose fibers.

The fiber so formed is washed, dried, and then finally shipped in bales to the manufacturers who then turn it to a final product.

The lignin that is made to separate out can be used for the creation of new products or made to burn for the production of bio-energy.

It is the fact that many modern pulp mills can produce more energy than they will be consuming for the making process of pulp by burning lignin.

After that electricity is provided to local homes and businesses by the mills.

This conservation helps to make modern pulp a much greener process than it used to be in the past.

The by-products that are produced in the pulp making process, such as turpentine and crude tall oil, are made to use for the creation of renewable diesel or any kind of biochemicals.

This process is another method which is applied by manufacturers for limiting waste and in-turn create a greener industry.

In Europe and U.S. nearly about 70-80% of the pulp-based paper and board products are properly recycled.

This recycling is not done just for once. It can be done for about 7 to 10 times. This helps in making products from pulp a bit more renewable and greener as compared to other types of manufacturing.

Also Read: Compressive Strength of Plywood

The Future of Pulp

Wood pulp is a reliable, strong, and quite versatile material.

Companies make it use for the manufacture of a wide varieties of products such as printing or writing papers, tissues, and board papers.

Last of all wood pulp is a primary fibre that is obtained through softwood and hardwood tree harvesting.

While nowadays there are various non-traditional uses of pulp.

The advancement in technology means that products that are made from pulp, or the residual of pulp making, that can be eaten by you, power your car, wear or can conduct medical research.

For example, biochemicals are not manufactured from standard pulp but with the help of variations of pulp making process.

The residuals or same raw materials for pulp making process can be used for manufacture of medical items.

In the future it is not known to anybody what creative idea will be made into use by scientists.

There are some other areas that might not be realized by you where wood pulp is used for its manufacture. Those are:

- Clothing

- Liquid Packaging Boards to be used in the coatings for various products like milk cartons

- Bioplastics

- Energy

- Medicine

For the alteration of fossil raw materials wood pulp is a best-suited alternative.

Fossil-based plastics might at some point of time be replaced by bioplastics, and oil-based chemicals might be replaced by biochemicals.

Anything can be easily be made from raw wooden materials, and scientists are at this moment are carrying out research for getting new materials and products.

It can surely be said wood pulp is not for paper anymore.

Is Wood Pulp Bad for You?

There are no known harmful side effects from adding it to food, and it’s completely legal. “Cellulose is a non-digestible plant fiber, and we actually happen to need non-digestible vegetable fiber in our food—that’s why people eat bran flakes and psyllium husks,” says Jeff Potter, author of Cooking for Geeks.

How Is Wood Pulp Made?

How is wood pulp made? To make pulp, the cellulose fibres of wood are mechanically or chemically separated. To make chemically separated pulp, wood chips are essentially cooked at high temperatures in a mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), a process that breaks it down to a pulp.

What Is Pulp Used for?

Pulp is used in a variety of consumer and specialty products, such as: paper printouts, receipts, post-its, envelopes. paper cups, napkins, toilet rolls, tissues. cardboard.

What Is Wood Pulp Used For?

Pulp is a renewable, biodegradable raw material made from trees. As one of the most versatile materials around, uses for pulp range from the everyday (e.g. tissues, books, and baby wipes) to the more innovative, such as car filters, LCD screens, renewable fuel, and stickers.

Pulping Process

The kraft pulping process (see Figure 10.2-1) involves the digesting of wood chips at elevated temperature and pressure in “white liquor”, which is a water solution of sodium sulfide and sodium hydroxide. The white liquor chemically dissolves the lignin that binds the cellulose fibers together.

Chemical Pulping

Chemical wood pulping involves the extraction of cellulose from wood by dissolving the lignin that binds the cellulose fibers together. The 4 processes principally used in chemical pulping are kraft, sulfite, neutral sulfite semichemical (NSSC), and soda.

Fast-Growing Trees for Paper Industry

The fastest growth rates were for Loblolly Pine and Hybrid Aspen, and the slowest for Black Spruce, with climate and temperature playing a large role in growth rates.

From Which Tree Paper Is Made

Paper is made from softwood or hardwood trees, but 85% of the wood pulp that makes paper in the U.S. comes from softwood coniferous trees. They have longer fibers known to produce stronger paper. The primary trees in this category are pines, firs, spruces, hemlocks, and larch.

Wood Pulp in Food

When trees are broken down to a fine powder at a pulp mill, the cellulose molecule extracted from pulp is the same cellulose found in the plant cell walls of fruits and vegetables. It is one of the most common food additives and has been FDA-approved since the mid-1900s.

How Many Trees Are Used to Make Paper?

1 ton of non-coated, not recycled office/print paper requires approximately 24 trees for production. 1 ton of the same kind of newspaper needs about 12 trees to create it. 1 ream of paper (500 sheets, not recycled and newly made) uses approximately 6 percent of a tree.

What Tree Is Used to Make Paper Money?

Some of the most commonly used softwood trees for paper making include spruce, pine, fir, larch and hemlock, and hardwoods such as eucalyptus, aspen and birch.

Wood Pulp Is Used to Make

Wood pulp is a versatile material used for a wide variety of products. “We can consider four main end uses for wood pulp. They are tissue, printing and writing papers, board and specialty papers.

Pulp and Paper Industry Outlook 2023

In 2023, global pulp and paper production will reach 490 million tons. According to projections by Pitney Bowes, global shipping volume is expected to surpass 100 billion parcels in 2023. Over 15% of pulp and paper sales in the United States will occur online by 2023.

Importance of Pulp and Paper Industry

Responsible pulp and paper operations can bring many benefits to forests, local economies, and people, particularly in rural areas. Many pulp and paper companies are demonstrating leadership in responsible forestry and plantation management as well as in clean manufacturing processes and recycled content.

Future of Paper

According to Pöyry’s World Paper Markets 2020, “world demand for paper and paperboard is forecast to grow by 2.1% annually in the long term, reaching an estimated 490 million tons by the year 2020.” Countries such as India and China show vastly increasing demand for paper for books, newspapers and periodicals.

Like this post? Share it with your friends!

Suggested Read –

Leave a Reply