What Is MDF?

Important Point

Medium-density fiberboard (MDF) is a type of wood product, often compared in discussions about mdf vs particle board.

The production of this type of MDF board is made of compressed wood fibers properly mixed with wax and resin. F MDF has the same properties as particleboard and hardboard.

The MDF board has a wide range of uses in a variety of industries. MFD boards can generally be used in the economy and interior.

Medium-density fiberboard (MDF) is light in weight, so it can be easily cut and shaped. In addition, waterproofing capability can be developed by painting on an MDF board.

Such properties make the MDF board an excellent material.

Medium Density Fiberboard

Medium-density fiberboard is popularly known in the market as MDF board. The name MDF board comes from the difference in the process of fiberboard.

MDF lattice-like design is used as the most popular application in many applications of materials. The price of an MDF board depends on factors like its various grades, finishing-laminated and thickness, etc.

MDF is produced by mixing a large amount of sawdust and wax produced by timber mills.

Large-scale production of MDF boards began in 1980. Today the use of MDF boards has become an alternative to the design provided for builders, woodworkers, and architects.

MDF fiberboard is often thicker and harder than plywood. It is made up of various fibers of the wood. So MDF can be used as a building material to replace plywood.

Medium-density fiberboard (MDF board) is usually the same density fiberboard as plywood. Medium-density fiberboard (MDF) in a building is very versatile and can be used effectively in cabinetry, furniture, and molding, which makes selection an option for entire projects.

Medium-density fiberboard (MDF) is sometimes finished with veneer or laminate, which provides the impression of the real wood grain.

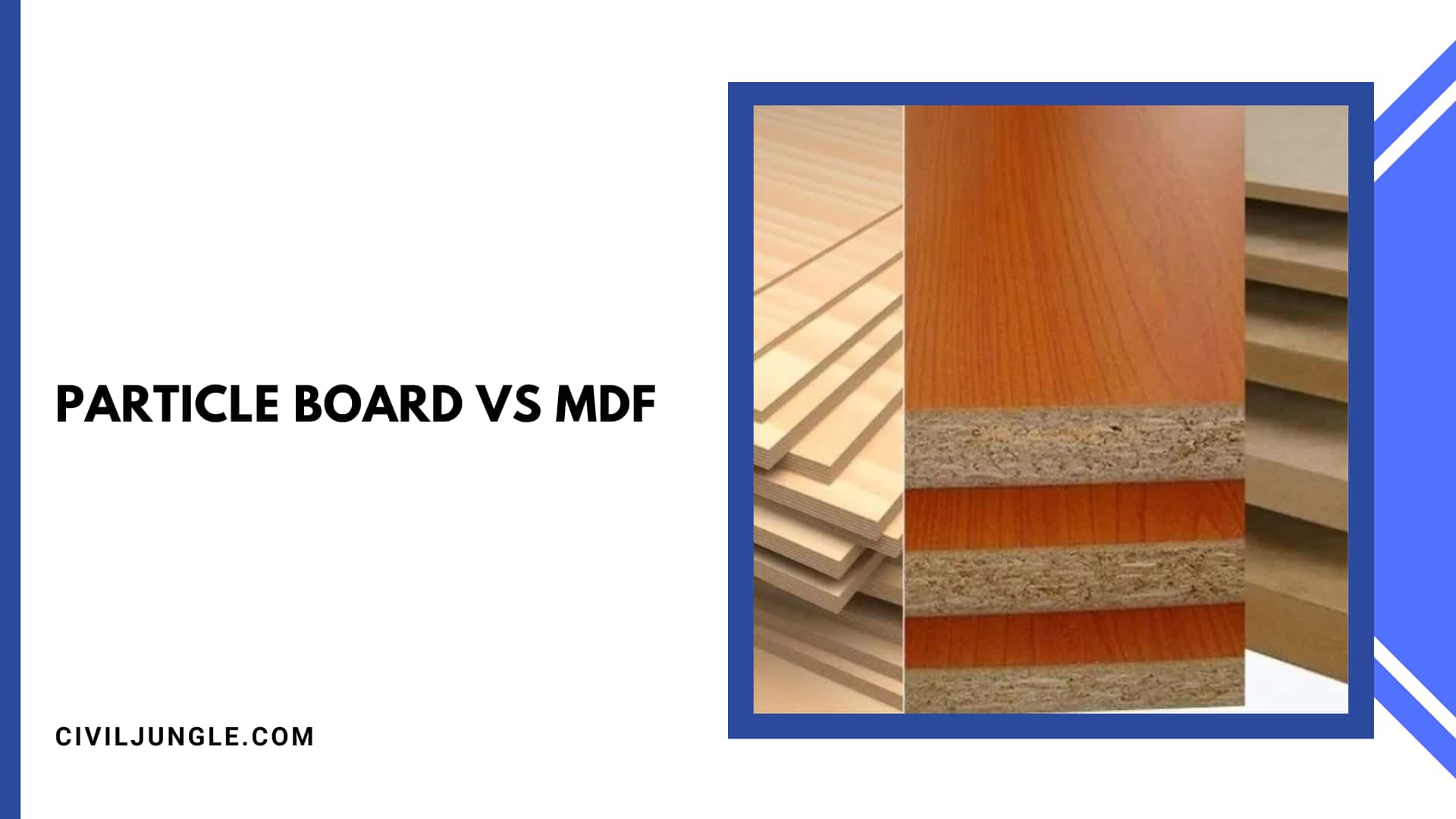

Particle Board Vs MDF

Here we will know the differences between some MDF boards vs. particle boards, essentially understanding the difference between mdf and particle board.

1. Particle Board Vs MDF: Density

MDF board: MDF has a higher density than particle board.

Particle Board: This type of partial board, often referred to in comparisons as particleboard mdf, has a lower density level than MDF.

2. Particle Board Vs MDF: Durability

MDF boards: Medium-density fiberboards are more durable than particle boards.

Particle boards: Particle boards are less durable than MDF boards.

3. Particle Board Vs MDF: Look

MDF board: MDF board has a smooth finish as it is made of the same size as the wood grain.

Particle boards: The surface of particle boards is not smooth compared to the MDF board. Because it is produced by cutting wood and chips.

4. Particle Board Vs MDF: Strength

MDF board: Medium-density fiberboard has higher strength than particle board.

Particle board: particle board has less strength than medium-density fiberboard.

5. Particle Board Vs MDF: Weight

MDF board: MDF board is heavier when compared to medium-density fiberboard with particle board.

Particle board: Particle board is lightweight compared to medium-density fiberboard.

6. Particle Board Vs MDF: Lifespan

MDF board: Medium-density fiberboard cannot be used for a long time. It can survive for about 10 years in the right conditions.

Particle boards: Particle boards have a longer life than MDF boards, which can last for more than 25 years.

7. Particle Board Vs MDF: Moisture

MDF board: Medium-density fiberboard absorbs water, which reduces his life.

Particle board: Particle board has moderate resistance to water.

8. Particle Board Vs MDF: Price

MDF board: The cost of medium-density fiberboard is higher than particle board.

Particle-board: Particle board is cheaper than an MDF board.

MDF Material Uses

Medium Density Fiberboard (MDF) is a construction-engineered commodity made from wood fibers, often compared when considering fiberboard vs particle board.

Its various uses are made for different commodities in different industries.

Some of the uses of the MDF board are as follows.

1. Cabinetry

MDF board, sometimes questioned, is mdf particle board? is generally known for the use of single-density fiberboard. It can be used in the interior cabinet of the house.

Cabinets made of MDF fiberboard can be finished with laminate to create the impression of the wood grain.

A platform can be created to place the interior of the house using the help board. It can be used in kitchen cabinets and shelving units.

MDF board can be used indoors and tables etc. In addition, moldings and sometimes wood grain impressions can be made on doors and tables.

MDF can be used internally in a variety of applications.

2. Furniture

The various practical uses of medium-density fiberboard (MDF) are versatile materials for working in a variety of furniture.

Many furniture companies use special-density medium-density fiberboards. In addition, you can use MDF board economically for your home furniture.

Furniture can be made from MDF, such as a bookshelf or a recreation center.

Many different economical furniture can be made using low to medium density fiberboard vs particle board.

This is because this type of MDF board can be easily manufactured for boards of different densities. And it is cheaper than other boards, which reduces the cost of manufacturing the furniture.

Low-density fiberboard can be made into furniture as needed, which reduces the cost of furniture. This has made the use of MDF boards very popular.

3. Fire Resistance

Fire retardant MDF can be used for non-structural applications, which can be done properly for applications like wall linings, partitions, display panels, etc., in indoor dry conditions.

Medium-density fiberboard is popular due to its firefighting ability.

Fireproof MDF boards are generally suitable for use in the construction of certain buildings and structures.

The use of the MDF board meets the requirements of fire safety in the construction of commercial buildings. This type of MDF board is suitable for use in stores and offices.

Some homeowners use fireproof MDF boards in the construction of new homes as protection from potential fire.

Also Read: Best 32 Stove Backsplash Ideas

4. Vapour Repulsion

Medium-density fire boards can be used as a vapor barrier and as insulation for residential and commercial buildings. Vapor-resistant furniture products affect durability and long life.

This type of MDF board is designed to dry large amounts of moisture without shrinkage. Or the MDF board dries without decomposition.

This type of MDF board acts as a vapor barrier and as insulation, which can avoid heat loss in adverse weather conditions.

5. Soundproofing

MDF fiberboard can be used as soundproofing. This type of MDF fiberboard can absorb and reduce noise for travel.

MDF-type fiberboard may not be effective in reducing soundness widely.

Sometimes MDF board is used by speaker manufacturers. This is because this type of MDF board prevents vibration from inside the speaker case.

MDF board can be used in media rooms, apartment buildings, and office walls, as well as floors. So that noise pollution can be reduced.

Many different contractors and builders use MDF boards in the construction of site offices for noise reduction.

6. Roofing

Due to the specialty of MDF fiberboard, it can be used both indoors and outdoors. MDF fiberboard can be used for roofing materials as a low-slope roof.

Medium-density fiberboard is a suitable material as a roofing material, which can be used as shingles in any type of roof. MDF fiberboard can be used as a covering for the walls of the house.

MDF fiberboard is durable and flexible, which can be used as decoration in the interior and exterior, which offers multiple applications for the home.

This list is just one example of some of the popular uses of medium-density fiberboard (MDF). This medium-density fiberboard (MDF) can be used in many ways.

MDF board can be used as an inexpensive alternative to wood products like plywood.

MDF Board Properties

- Thickness

- Water Absorption

- Modulus of Rupture

- Elasticity

- Swelling

- Internal Bond Strength

- Modulus of Elasticity.

Also Read: Best 26 Outdoor Grill Exhaust Hood Ideas

Application of MDF Board

- Furniture

- Speaker boxes

- Doors and door frames

- Cabinets and Shelves

- Flooring

- Decorative projects

- Wainscoting

- Flooring

- Tradeshow booths and theatre set construction.

Advantages of MDF Board

The advantages of using an MDF board are as follows,

- Medium-density fiberboards are made from wood resin. Which is a recycling process. So that the cuts can be minimized

- This type of MDF board can be painted. Which can last a long time on the paint surface.

- The MDF Board is financially viable for the general public because it is more economical than the cost of wood.

- Medium-density fiberboard does not have grains like wood. But laminating over it can produce wood-like grains.

- This type of help board can be easily cut and shaped. In which nail fix is done without any damage from the hammer.

- Properties like strong, dense, flat, hard etc., can be used properly instead of wood of medium-density fiberboard.

- MDF fiberboard can be given the look of natural wood veneers using laminators.

- The MDF board can be used easily. It can be easily given any shape.

Disadvantages of MDF Board

Some of the disadvantages of the MDF Board are shown below

- Medium-density fiberboard is weaker than wood. Furniture made from MDF cannot be used for a long time. However, medium-density fiberboard is not more expensive than wood. So if it is to be used for a long time, it seems to be a loss of money.

- Medium-density fiberboard cannot withstand extreme stress. As a result, it breaks down.

- Medium-density fiberboard has the property of absorbing water faster than wood. As a result, the MDF board swells and slowly begins to break. So everyone should consider using MDF in humid places.

- The nail and screw in the medium-density fiberboard should be carefully fixed. The use of a hammer should be avoided while fixing the nail in MDF. The MDF board is very weak. Pilot gaps should be used for screw fixing.

- Particular care should be taken when cutting medium-density fiberboard as the production of MDF includes urea-formaldehyde. Which can cause inflammation in the lungs and eyes

- Dust produced when cutting the MDF board is harmful to respiration.

MDF Manufacturing Process

The production process of MDF is described in detail below

- Collection.

- Wood preparation.

- Resin recipes.

- Press technique.

- Panel sanding technique.

- Finishing.

Step 1. Collection

The first steps for MDF involve the collection and grinding of wood residue as raw material. Wood resin is waste produced in mills.

The debarking process is the initial step for the production of the MDF Board. The bark of the eucalyptus softwood is peeled off to give it the right quality.

Step 2. Wood Preparation

Iron impurities in wood are removed using magnet metal. These raw materials are separated into large lobes and small peaches.

In the refiner, the material of this raw material is torn into fibres. This process is done by large motor units.

Step 3. Curing and pressing

Resins are applied in the process to reduce the resistance to formaldehyde. And then, the catalyst is added. The amount of resin for MDF is controlled by the required volume.

Presented in a mat or pad with a uniform thickness using a scaling roll

The compression of these materials is done in two stages. The final process is to cut it to the required size. Using a large drum, it is placed on a mat or pad to compact. This prepared board is cut before cooling.

Step 4. Panel Sanding

The finished panels are sent to MDF Board for a smooth finish. It has a finishing coating with friction through the use of belts.

Various ceramic frictions are used for this. Zirconium alumina, aluminum oxide, silicon carbide, etc., are used to obtain fine surfaces for these various ceramic frictions.

Step 5. Finishing

The first phase of finishing begins with cutting. The final stage of MDF varies depending on customer demand.

The design is given according to the variety of colors of MDF and the variety of wood grain. For cutting different sizes of MDF, different cutting machines are used.

Special machines are used to cut narrow strips like 1-24 inches / 2.5-61 etc.

(42-49 inches / 107-125 cm) are used for small-size cutting machines.

guillotine cutting machine is used to cut to sizes as large as 100 inches

The second stage of finishing is done as laminating. Fiberboard is sent between two rolls in the machine. The adhesive is applied between two rolls in the machine. Thus MDF is coated with fiberboard adhesive.

Also Read: Best 26 Outdoor Grill Exhaust Hood Ideas

Like this post? Share it with your friends!

Suggested Read –

- 16 Types of Dams

- What Are Green Roofs?

- Types of Movable Walls

- What Is Shoring And Their Types

- Best Guide to Kitchen Linoleum Flooring

What Is MDF Made Of?

MDF is made from wood fibers, resin, and wax, which are compressed under high pressure and temperature to form a dense, durable panel.

How Does MDF Differ from Particle Board?

MDF is denser, stronger, and has a smoother surface compared to particle board, which is lighter, less durable, and has a rougher texture due to visible wood chips.

Can MDF Be Painted?

Yes, MDF can be easily painted. Its smooth surface provides an excellent base for paint, allowing for a high-quality finish.

Is MDF Waterproof?

Standard MDF is not waterproof and absorbs water, which can cause swelling and damage. However, moisture-resistant MDF is available for applications in humid environments.

Where Is MDF Commonly Used?

MDF is used in cabinetry, furniture, molding, doors, shelving, flooring, and various decorative projects. It is also used in speaker boxes, roofing, and soundproofing applications.

Is MDF Environmentally Friendly?

MDF is made from recycled wood fibers, making it an environmentally friendly option. However, the production process involves formaldehyde-based resins, which can be a concern for indoor air quality.

How Should MDF Be Handled During Installation?

When cutting or sanding MDF, it is important to wear a mask to avoid inhaling dust, which contains formaldehyde and can irritate the lungs. Pre-drilling pilot holes is recommended to prevent splitting when nailing or screwing into MDF.

Can MDF Be Used Outdoors?

Standard MDF is not suitable for outdoor use due to its susceptibility to moisture. For outdoor applications, moisture-resistant or exterior-grade MDF should be used.

Leave a Reply