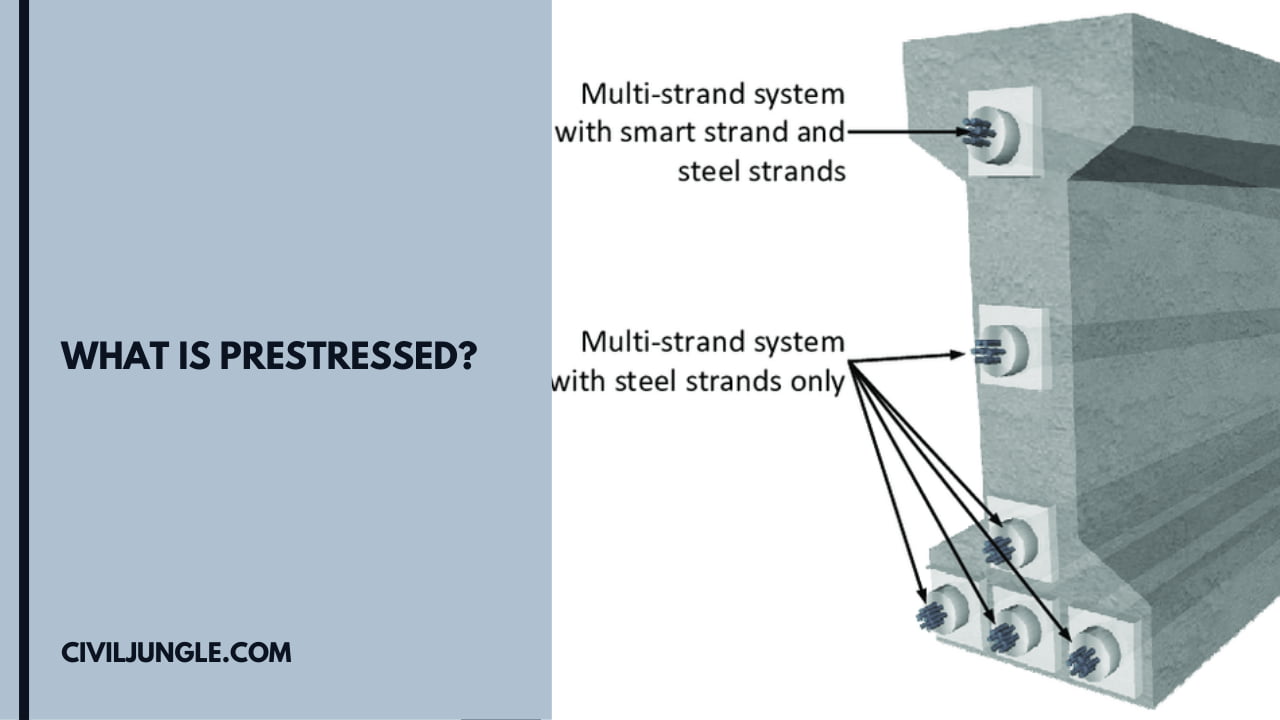

What Is Prestressed?

Important Point

In ordinary reinforced concrete, tensile stresses by steel alone and compressive stresses are taken up by concrete. This concrete below the neutral axis is ignored since it is weak in tension.

Although steel takes up to the tensile stresses, the concrete at the tensile zone develops minute cracks. The load-carrying capacity of such concrete sections can be increased if steel and concrete both are stressed before the application of external loads.

This is the concept of prestressed concrete. As per the ACI committee, prestressed concrete is that concrete in which internal stresses of suitable magnitude are introduced so that these stresses resulting from the external loadings can be counteracted to a desired degree.

In RCC members, prestress induced is of compressive nature so that it balances the tensile stresses produced due to external load. It makes the whole section effective (the concrete area in the tension zone also !) in resisting loads.

Also, read: What Is Lap Length | Lap Length of Column | Lap Length of Slab | Lap Length of Beam

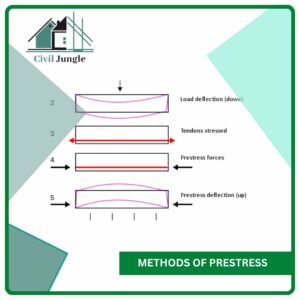

Methods of Prestress

Prestress may be induced in the structure by various prestressing methods. Some of which are explained below :

Internal Prestressing

In this system, a prestressing force is applied to the high tensile steel, i.e., the steel reinforcement. It induces internal compressive stresses in concrete. This most commonly used method because of the easy and accurate application.

Internal prestressing can be done by two different methods :

- Pre-tensioning

- Post-tensioning

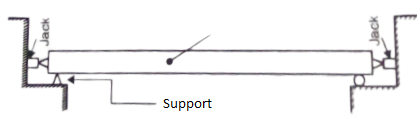

External Prestressing

- This method is not commonly used.

- In this method, the prestressing is done by adjusting the external reactions (by introducing different support conditions).

- In as per below fig, simply supported beam is prestressed externally by jacks.

- The externally prestressing system requires very much accuracy in planning and application.

Externally prestressing system for a simply supported beam.

Also, read: What Is Cover in Concrete | Clear Cover in Beams, Slab, Column, Footing

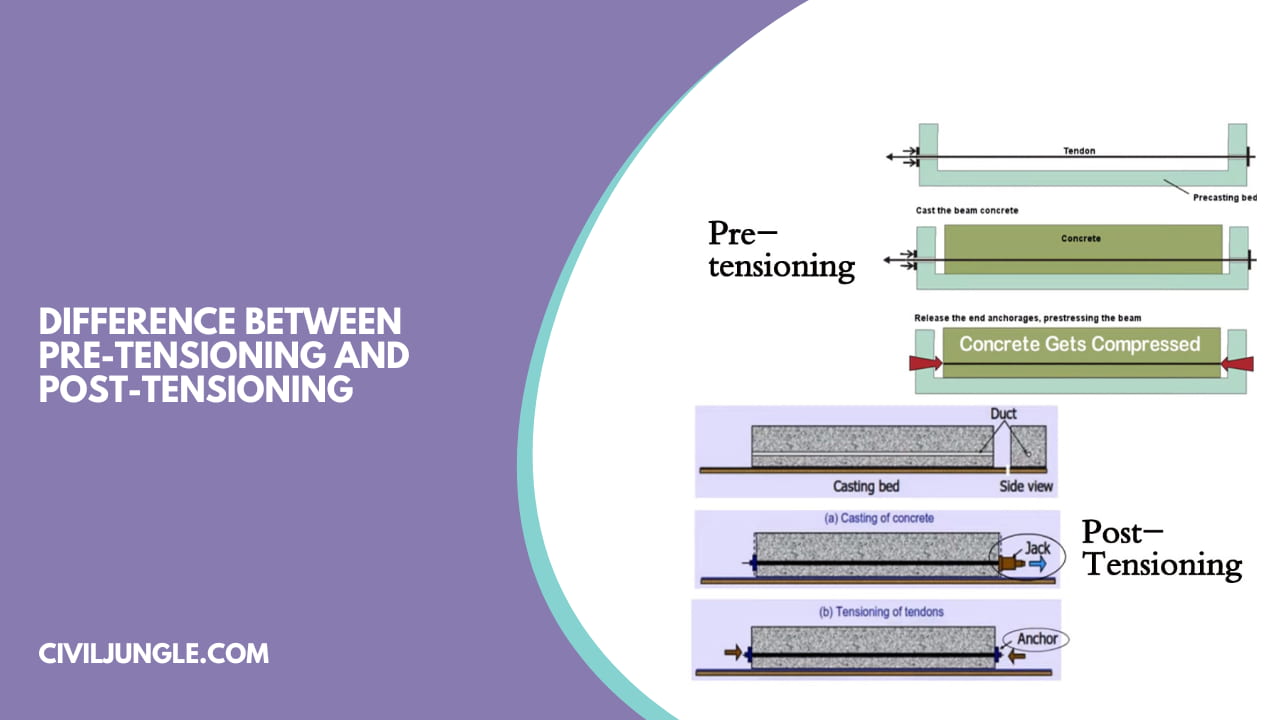

1. Pre-Tensioning

In Pre-tensioning, the steel tendons are tensioned before the concrete is cast. The tendons are temporarily anchored against some abutments and then cut or released after the concrete has been placed and hardened.

The prestressing force is transferred to this concrete by the bond along the length of the tendon. Pre-tensioning is generally done in precasting plants in permanent beds, which are used to produce Pre-tensioned precast concrete elements for the building industry.

2. Post-Tensioning

In Post-tensioning, the steel tendons are tensioned after the concrete has been cast and hardened.

Post-tensioning is performed by two main operations: tensioning the steel wires or strands by hydraulic jacks that stretch the strands while bearing against the ends of the member and then replacing the jacks by permanent anchorages that bear on the member and maintain the steel strands in tension.

A tendon is generally made of wires, strands, or bars. Wires and strands can be tensioned in groups, whereas bars are tensioned one at a time.

In the post-tensioning process, the steel tendons are placed in the formwork before the concrete is cast, and the tendons are prevented from bonding to the concrete by waterproof paper wrapping or a metal duct (sheath).

Tendons bonded to the concrete are called bonded tendons. Unbonded tendons, left without grout or coated with grease, have no bond throughout the length of the tendon.

Also, read: Piling for Foundation | Use of Pile Foundation | Characteristics of Pile Foundation

Difference Between Pre-Tensioning and Post-Tensioning

| Sr.No. | Pre-Tensioning | Post-Tensioning |

| 1 | Pre-tensioning is done in the factories thus suitable for precast construction works | Post-tensioning can be done in factories as well as on the site |

| 2 | In this type of concrete, the pre-stressing cables called the strands are tensioned before casting the concrete and then concrete is casted enclosing the tensioned cables. | In this type of concrete, the strands are enclosed within a duct in the form and then concrete is casted. The process of tensioning the strands is carried out after the concrete attains its sufficient strength. |

| 3 | Small sections are to be constructed | Size of a member is not restricted, long-span bridges are constructed by post-tensioning |

| 4 | Loss of prestressing isn’t less (about 18 %) | Loss of prestressing isn’t more (about 15 %) |

| 5 | In this method, similar prestressed members are prepared. | In this method, products are changed according to a structure. |

| 6 | Pre-tensioning members are produced in a mould. | Cables are used in place of wires and jacks are used for stretching. |

| 7 | In this method, the concrete is prestressed with tendons before it is placing in position | In this method prestressing is done after the concrete attains sufficient strength. |

| 8 | This method is developed due to the bonding between the concrete and steel tendons. | This method is developed due to bearing. |

| 9 | Pre-tensioning is preferred when the structural element is small and easy to transport. | Post-tensioning is preferred when the structural element is heavy. |

| 10 | It is cheaper because the cost of sheathing is not involved | It is costlier because of use of sheathing |

| 11 | It is more reliable and durable | The durability depends upon the two anchorage mechanism |

What Is Pre Tensioning?

In pre–tensioning the reinforcement, in the form of tendons or cables, is stretched (put into tension) across the concrete formwork before the concrete is placed. After the concrete has hardened and a suitable strength developed, the tendons are released.

Pre Tensioning

In pre–tensioning the reinforcement, in the form of tendons or cables, is stretched (put into tension) across the concrete formwork before the concrete is placed. After the concrete has hardened and a suitable strength developed, the tendons are released.

What Is Post Tensioning Concrete?

Post–tensioning is a method of prestressing in which the tendons are tensioned after the concrete has hardened and the prestressing force is primarily transferred to the concrete through the end anchorages.

What Is Pre and Post Tensioning?

Most precast, prestressed concrete is actually pre–tensioned-the steel is pulled before the concrete is poured. Post–tensioned concrete means that the concrete is poured and then the tension is applied-but it is still stressed before the loads are applied so it is still prestressed.

Pre Tensioning and Post Tensioning

Most precast, prestressed concrete is actually pre–tensioned-the steel is pulled before the concrete is poured. Post–tensioned concrete means that the concrete is poured and then the tension is applied-but it is still stressed before the loads are applied so it is still prestressed.

What Is Post Tensioning in Concrete?

Post–tensioning is a method of prestressing in which the tendons are tensioned after the concrete has hardened and the prestressing force is primarily transferred to the concrete through the end anchorages.

Post Tensioning Concrete

Post tensioning is a technique for reinforcing concrete. Post–tensioned concrete means that the concrete is poured and then the tension is applied-but it is still stressed before the loads are applied so it is still prestressed. For an excellent overview of PT, visit the Post–Tensioning Institute.

Post Tension Vs Conventional

Post–tensioned concrete is stronger and more flexible than conventional steel-reinforced concrete. According to the Concrete Network, post–tensioning helps reduce cracking from shrinkage as the concrete dries, and holds together any cracks that do form.

Pretensioned and Post Tensioned Concrete

Prestressing simply means that the steel is stressed (pulled or tensioned) before the concrete has to support the service loads. Post–tensioned concrete means that the concrete is poured and then the tension is applied-but it is still stressed before the loads are applied so it is still prestressed.

What Is the Difference Between Pre Tensioning and Post Tensioning?

Pretension is the technique in which we are imparting tension in strands before placing the concrete. Post tensioning is done by forming a duct in which strands are pulled (tensioned) after the concrete gains it’s full strength.

How Pre-Tensioning Is Done?

In pre–tensioning the reinforcement, in the form of tendons or cables, is stretched (put into tension) across the concrete formwork before the concrete is placed. After the concrete has hardened and a suitable strength developed, the tendons are released. A compressive force is therefore induced into the concrete.

What Are the Methods of Post-Tensioning?

- Freyssinet System.

- Magnel System.

- Leonhardt System.

- Lee-Mccall System.

- Gifford-Udall System.

Difference Between Pre Tensioning and Post Tensioning

In Pre-tensioning, steel wires are tensioned before concrete is placed and hardened. In Post-tensioning, steel wires are stretched out once the concrete is settled and hardened.

Difference Between Pretension and Post Tension

Pretension: Tensioning the reinforcement before pouring the concrete.

Post-tension: Tensioning the reinforcement after the concrete has hardened.

Pretensioning and Post Tensioning

In Pre-tensioning, steel wires are tensioned before concrete is placed and hardened. In Post-tensioning, steel wires are stretched out once the concrete is settled and hardened. In post-tensioning, the longitudinal profile of the steel wires can be placed at any desired profile.

Pre Tension Slab

A pretension slab is a type of concrete slab where the reinforcement is tensioned before pouring the concrete, enhancing its strength and load-bearing capacity.

Difference Between Post Tensioning and Pre Tensioning

Post-tensioning is done after the concrete is hardened using high-strength steel strands or cables, while pretensioning is done before pouring the concrete, anchoring the reinforcement to the formwork or abutments. Post-tensioning allows for adjustment of tension after concrete hardens, while pretensioning has less flexibility. Post-tensioning is commonly used in cast-in-place construction, while pretensioning is used in precast construction.

Pre Tensioning System

In pretensioning, lengths of steel wire, cables, or ropes are laid in the empty mold and then stretched and anchored. After the concrete has been poured and allowed to set, the anchors are released and, as the steel seeks to return… In construction: The concrete dome. … technology with the introduction of pretension.

Post Tension Vs Pre Tension

The main difference between the two techniques is the timing of tensioning: post-tensioning occurs after concrete hardening, while pretensioning occurs before pouring the concrete. Post-tensioning offers more flexibility for adjusting tension, while pretensioning is suitable for precast elements.

Post Tensioning and Pre Tensioning

post-tensioning involves tensioning after concrete hardens, while pretensioning involves tensioning before pouring concrete. Post-tensioning provides flexibility in adjusting tension, while pretensioning is commonly used in precast construction.

Methods of Prestressing

Prestressing Concrete Systems are carried in two ways:

- Pre-tensioning Method.

- Post-tensioning Method.

Like this post? Share it with your friends!

Suggested Read –

- Difference Between Lap Length and Development Length

- Difference Between One Way Slab and Two Way Slab | What is Slab

- Difference Between Timber And Wood | What is Wood | What is Timber

- Difference Between M Sand Vs River Sand | What is M-Sand & River Sand

- Difference Between Footing and Foundation | What is Footing and Foundation

- Difference Between OPC Vs PPC | What is Cement | OPC Cement | PPC Cement

- Difference Between Short Column and Long Column | What Is Column | Type of Column

- Difference Between Flexible Pavement and Rigid Pavement | What is Pavement | Type of Pavement

what is the difference between pre tensioned or pre stressed?

The difference is that in pre-tensioned concrete, the tendons are tensioned prior to pouring of concrete while in post-tensioned concrete, tendons are tensioned after putting concrete.