What Is Development Length?

Important Point

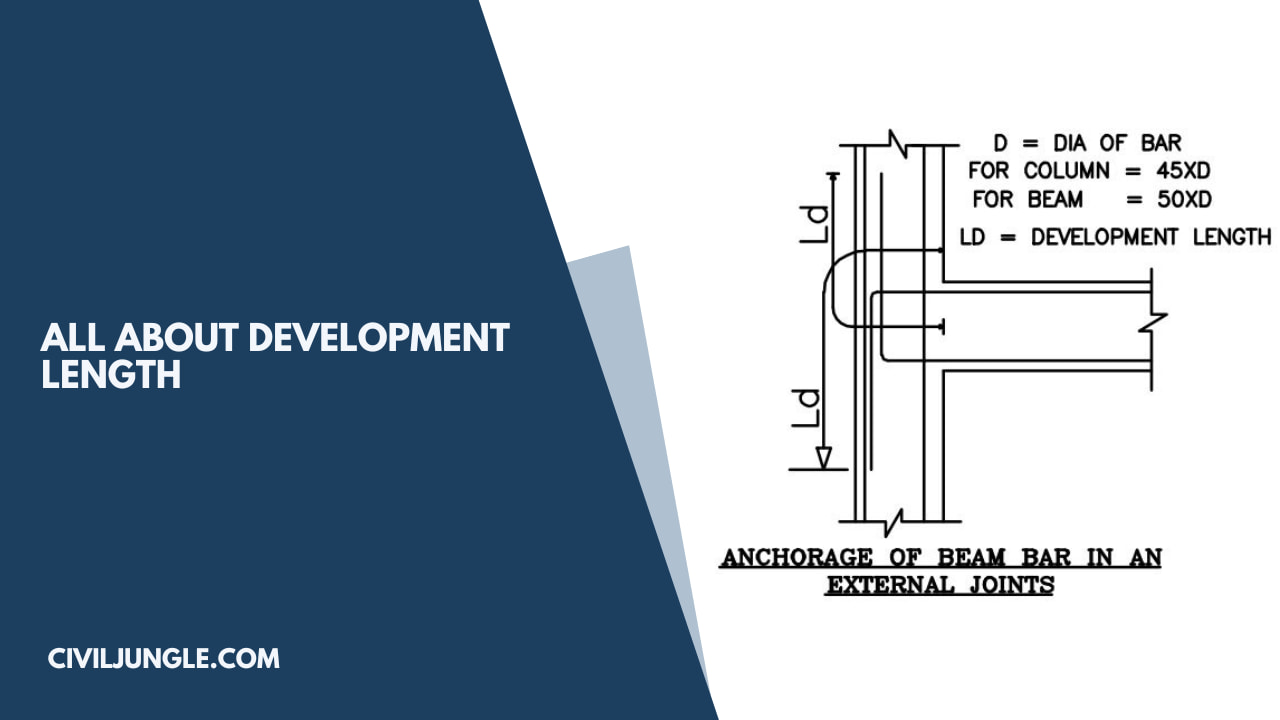

A development length can be defined as the amount of reinforcement(bar) length needed to be embedded or projected into the column to establish the desired bond strength between the concrete and steel

Length of development of reinforcement bars. A growth length can be defined as a length of reinforcement (bar) that must be embedded or projected into the column to establish.

Reason for providing the length of development

- Develop a secure bond between the surface of the bar and the concrete so that any failure due to slippage of the bar does not occur during the final load conditions.

- Furthermore, the additional length of the bar provided as the length of the growth is attributed to the stresses developed in any section of adjacent sections (such as the additional length of the bar provided from the beam to the column at the column beam junction).

Also, read: What Is Camber in Road | Types of Camber | Advantages of Camber in Road

Importance of Development Length

The provision of appropriate development is an important aspect of safe construction practices. Proper development lengths in reinforcement bars shall be provided according to the steel grade considered in the design.

Otherwise, in scenarios where the required growth length is short provided the structures will suffer failure due to the slippage of joints, slippers, anchors, and laps, in such cases, the bars will not pass first, but the failure will occur in joints and laps, before the yield of reinforcement bars.

Also, read: Carbon Steel vs. Stainless Steel | What Is Carbon Steel | What Is Stainless Steel

What Is Development Length of Bars?

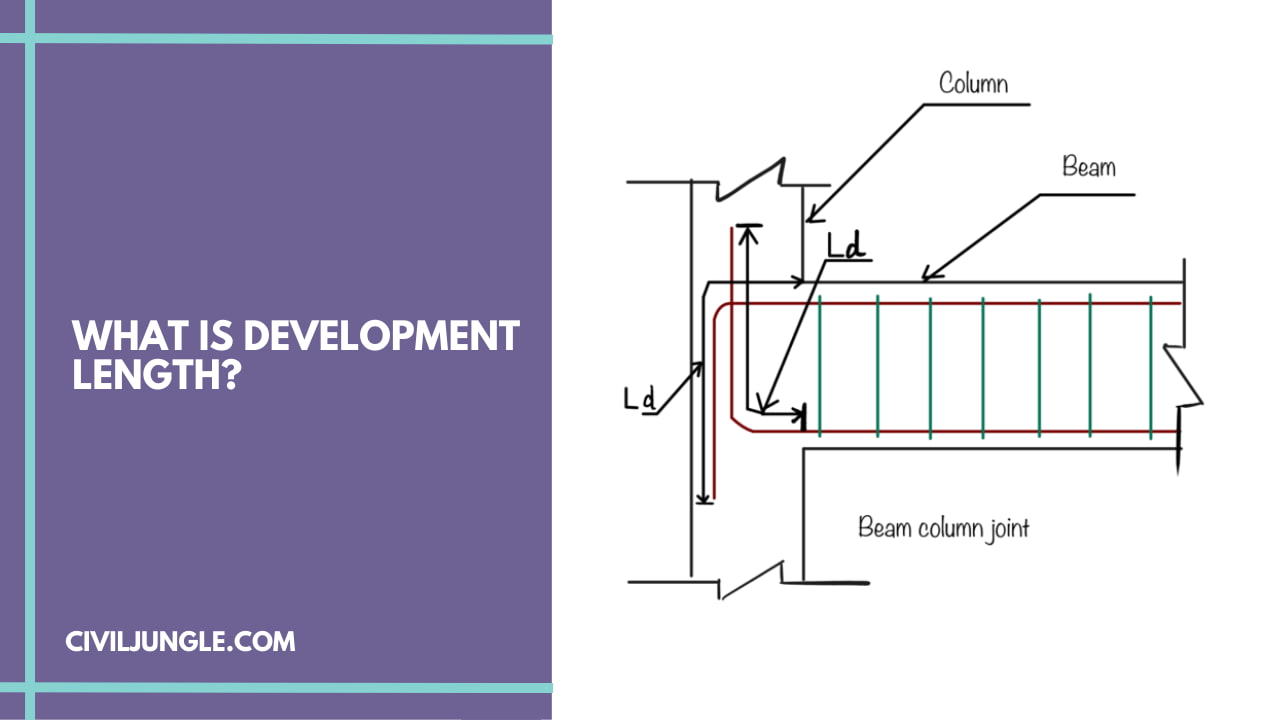

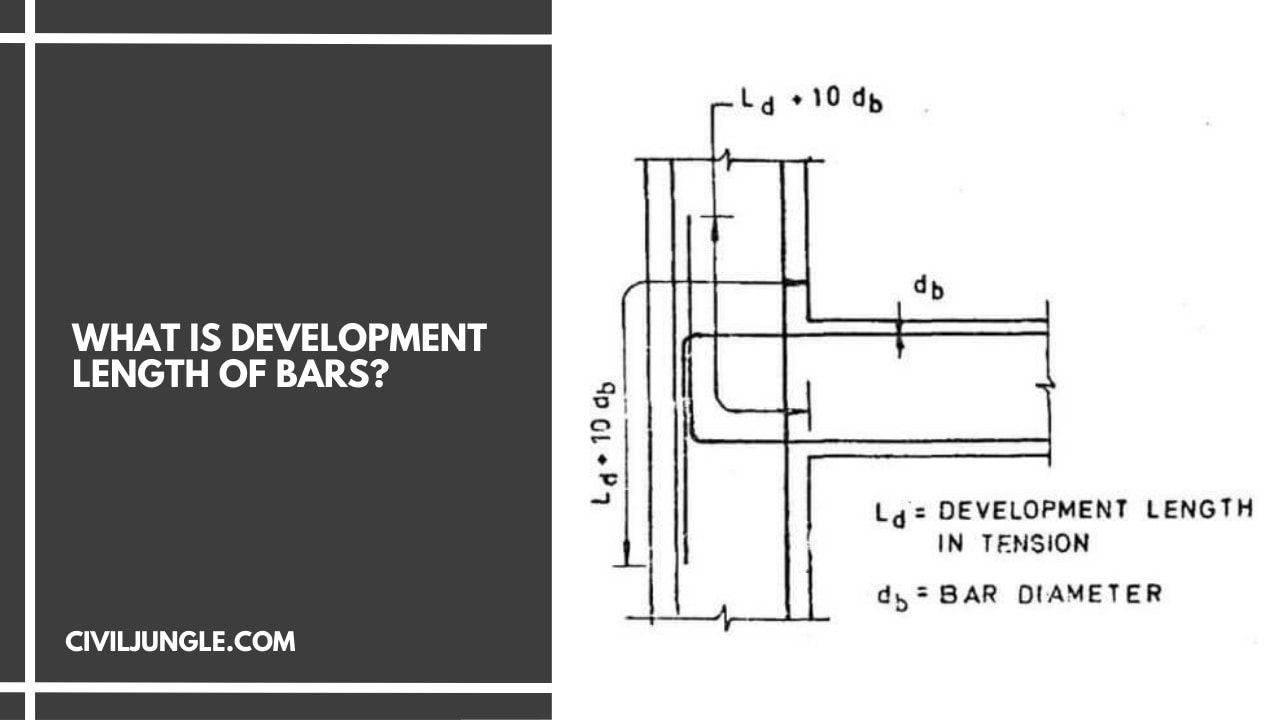

The growth length can be depicted as the length of the bar required to transfer the stress to the concrete.

A growth length is the amount of rebar length that is needed to actually create the desired bond strength between two materials to engage in concrete and furthermore to produce the required stress in steel in that area.

The growth length is essentially provided to form a bond between steel and concrete so that the bar force can be transferred without the slip to prevent the bar from pulling out under tension.

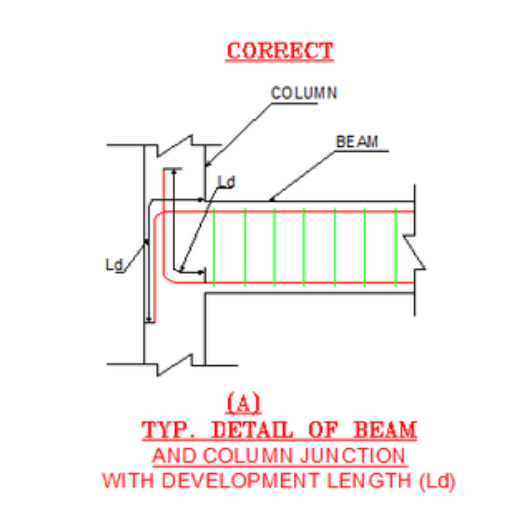

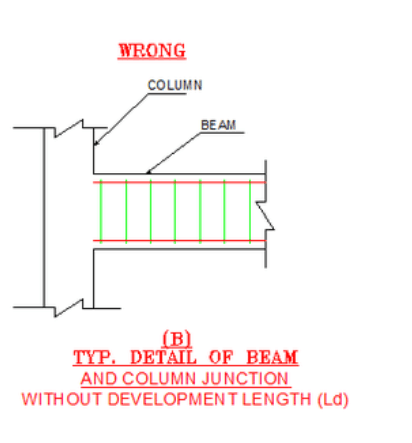

- Image A: Development length is provided at the beam and column junctions. The stresses developed due to this are easily transferred by bonds created by steel and concrete.

- Image B: The length of the growth at the beam and column junction is not provided. Due to this, the tension developed in the beams will not be able to transfer it to the column.

- Lap length: The lap length is the minimum length that must be generously provided if the two bars are joined together so that forces can be easily transferred.

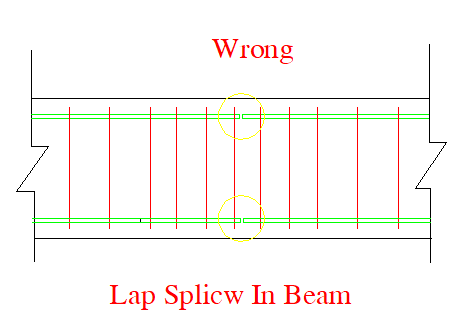

Image C

- Image C: Check the image if the bars are not overlapped, so no force is transferred.

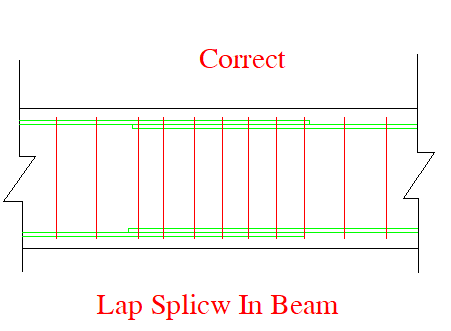

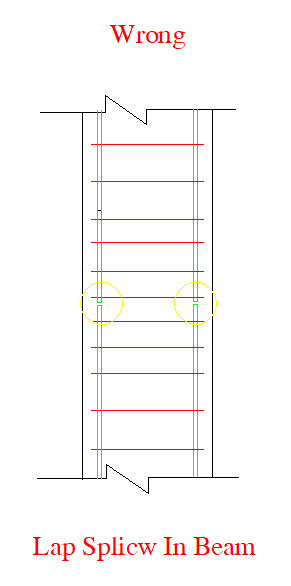

Image D

- Image D: Check the lap splice in the beam. The length of the overlap varies depending on the flexural tension, direct tension, and compression. In our practical site condition, it is taken to be approximately 50 x the diameter of the bar.

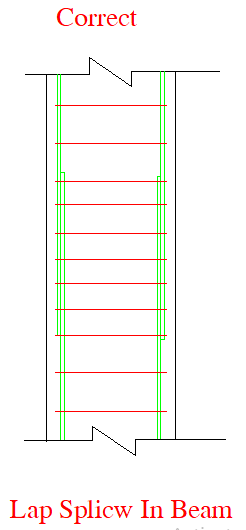

Image E

- Image E Overlapping is done in most columns because the column can reach more than 100 m. The bars are cut in every other story of the building to simplify the work for the workers.

Image F

- Image F: If not done in the overlapping column, the forces will not be shifted.

Important things to remember:

- Lap spice shall not be used for bars greater than 36 mm diameter, in which case the bars will be welded.

- Lap spikes will be away from the maximum stress section.

Development Length

A development length can be defined as the amount of reinforcement(bar) length needed to be embedded or projected into the column to establish the desired bond strength between the concrete and steel (or any other two types of material).

What Is Ld in Steel?

Ld is embedded length of the steel bar. For any given diameter of the bar, this formula is used to calculate the required development length in mm, and for limit state method as well as working stress method the same formula is used.

What Is Effective Length?

Effective length is a critical concept in Structural Design which relates to ‘the length of a component which is effectively restrained’.

What Is Developed Length?

A development length can be defined as the amount of reinforcement(bar) length needed to be embedded or projected into the column to establish the desired bond strength between the concrete and steel (or any other two types of material).

What Is the Length of Steel Bar?

The deformed Reinforcing Steel Bar is supplied in length of 9m or 12 m as common sizes. The steel bar diameter applied is different and accordingly the weight varies.

Where Is Lapping Provided in Beam?

Since the beam is not subjected to the negative moment at the mid-section thus it is desirable to provide lapping in this section. On the other hand, for the bottom reinforcement, it is desirable to provide the lapping at the end sections of the beam.

What Is Development Length of Steel?

A development length can be defined as the amount of reinforcement(bar) length needed to be embedded or projected into the column to establish the desired bond strength between the concrete and steel (or any other two types of material).

What Is Development Length Formula?

The Formula of Development Length: φ is the diameter of the bar. For any given diameter of the bar, this formula is used to calculate the required development length in mm, and for limit state method as well as working stress method the same formula is used.

What Is Tension Development Length?

Strictly speaking, tension development length refers to the anchorage length required to develop the full yield strength of the rebar embedded in concrete. On the other hand, splice length is the length required to fully transfer the force from one bar to the adjacent bar.

What Is the Use of Development Length?

The development length is needed to provide support to the beam to reduces the chances of the beam coming out of the concrete column. Hence it acts as a supporting member for reinforced beam in the concrete column.

How Do You Calculate Developed Length?

- Align a tape measure along the center of a pipe and measure the pipe’s length. Write down the measurement. For example, the pipe might be 8 inches long.

- Write down the appropriate measurement for the fitting that is used on the specific type of pipe. For example, the socket depth for a 1-inch plastic pipe is 3/4 inch.

- Multiply the fitting measurement times 2 to account for the fittings on either end. Using the previous example of a 3/4-inch fitting, you would multiply 3/4 times 2 to get 1 1/2 inches.

- Add your answer from Step Three to the length from Step One to get the determined length of the pipe. In this example, you would add 1 1/2 to 8 to get a determined length of 9 1/2 inches.

What Is Development Length as Per Is 456?

According to IS 456:2000, the minimum development length should be 41Ф.

What Is the Purpose of Development Length?

The development length is needed to provide support to the beam to reduces the chances of the beam coming out of the concrete column. Hence it acts as a supporting member for reinforced beam in the concrete column.

What Is Development Length and Lap Length?

Lap length is required when bars placed short of their required length (due to nonavailability of longer bars) need to be extended. lap length is to be provided to safely transfer the load. Development length is provided to transfer the load from steel to concrete. It is also known as anchorage length.

What Is Development Length and Why It Is Required?

A development length can be defined as the amount of reinforcement(bar) length needed to be embedded or projected into the column to establish the desired bond strength between the concrete and steel (or any other two types of material).

What Is the Minimum Development Length for Rebar?

The development length shall not be less than 12”. 4. N/A – Not applicable because rebar spacing corresponding to the cb value would not meet minimum spacing requirements based on an assumed maximum aggregate size of 1.0”.

What Is Difference Between Lap Length and Development Length?

Lap length is to be provided to safely transfer the load. Development length is provided to transfer the load from steel to concrete. It is also known as anchorage length.

How Do You Find the Development Length of a Circle?

The circumference = π x the diameter of the circle (Pi multiplied by the diameter of the circle). Simply divide the circumference by π and you will have the length of the diameter. The diameter is just the radius times two, so divide the diameter by two and you will have the radius of the circle.

What Is the Formula of Development Length for Slab as Per IS 456?

The respective development lengths of each of the bars for two, three or four bars in contact are determined following the same principle. However, cl. 26.2.1.2 of IS 456 stipulates a simpler approach to determine the development length directly under such cases and the same is given below:

“The development length of each bar of bundled bars shall be that for the individual bar, increased by 10 per cent for two bars in contact, 20 per cent for three bars in contact and 33 per cent for four bars in contact.”

However, while using bundled bars the provision of cl. 26.1.1 of IS 456 must be satisfied. According to this clause:

- In addition to single bar, bars may be arranged in pairs in contact or in groups of three or four bars bundled in contact.

- Bundled bars shall be enclosed within stirrups or ties to ensure the bars remaining together.

- Bars larger than 32 mm diameter shall not be bundled, except in columns.

Curtailment of bundled bars should be done by terminating at different points spaced apart by not less than 40 times the

Development Length in Slab

The development length is influenced by several factors, including the concrete strength, rebar diameter, concrete cover, and the type of loading conditions. It is typically determined based on the provisions specified in the design codes or standards, such as the ACI 318 (American Concrete Institute) or Eurocode.

What Is Development Length?

The term “development length” signifies the bar length that must be present for the stress to be transferred successfully into the concrete. For concrete and steel, it is the length of the bar that must be implanted into the material to generate enough tension to provide the appropriate bond strength.

Development Length in Column

Development length is the amount of reinforcement embedded in a column to achieve the suitable bond strength between the steel and concrete. It has a crucial role to play in the stability of a structure as it helps to prevent joint slippage.

Development Length Formula

The formulas for development length in a slab are as follows:

- ACI 318 Development Length Formula:

- L_d = [(φ * F_y * d_b) / (4 * τ_b)] * [(1 + √(1 + ((4 * τ_b) / (φ * F_y))))]

- Eurocode Development Length Formula:

- L_d = [(ψ * σ_s * A_s) / (λ * f_ck^(1/3))]

Development Length for Beam

It is the steel bar length required to be inserted into the concrete to develop the desired bond strength. This steel bar length holds two concrete members together like beam and column.

What Is Development Length in Column?

The development length in a column refers to the minimum distance required for the reinforcement bars (rebars) to extend beyond a point of critical section to ensure proper bond and transfer of forces between the rebars and the surrounding concrete. It is an important consideration in reinforced concrete column design to ensure structural integrity and load-carrying capacity.

Like this post? Share it with your friends!

Suggested Read –

- Top 10 Tiles Companies in India 2021

- Difference Between Carpet Area and Built-up Area

- Difference Between CPM and PERT | What Is CPM & PERT

- Difference Between One Way Slab and Two Way Slab | What is Slab

- What Is a Field Dry Density Test | Different Type of Field Density Tests

- What Is Plaster | Plaster Ratio | History of Plastering | Requirements of Good Plaster

- What Is Glass Fiber Reinforced Gypsum | Applications of GFRG | Disadvantages of The GFRG Panel

Leave a Reply