What Is Dampness?

Important Point

The most common source of dampness is due to the capillary attraction of sub-soil water in the foundation and walls of the building.

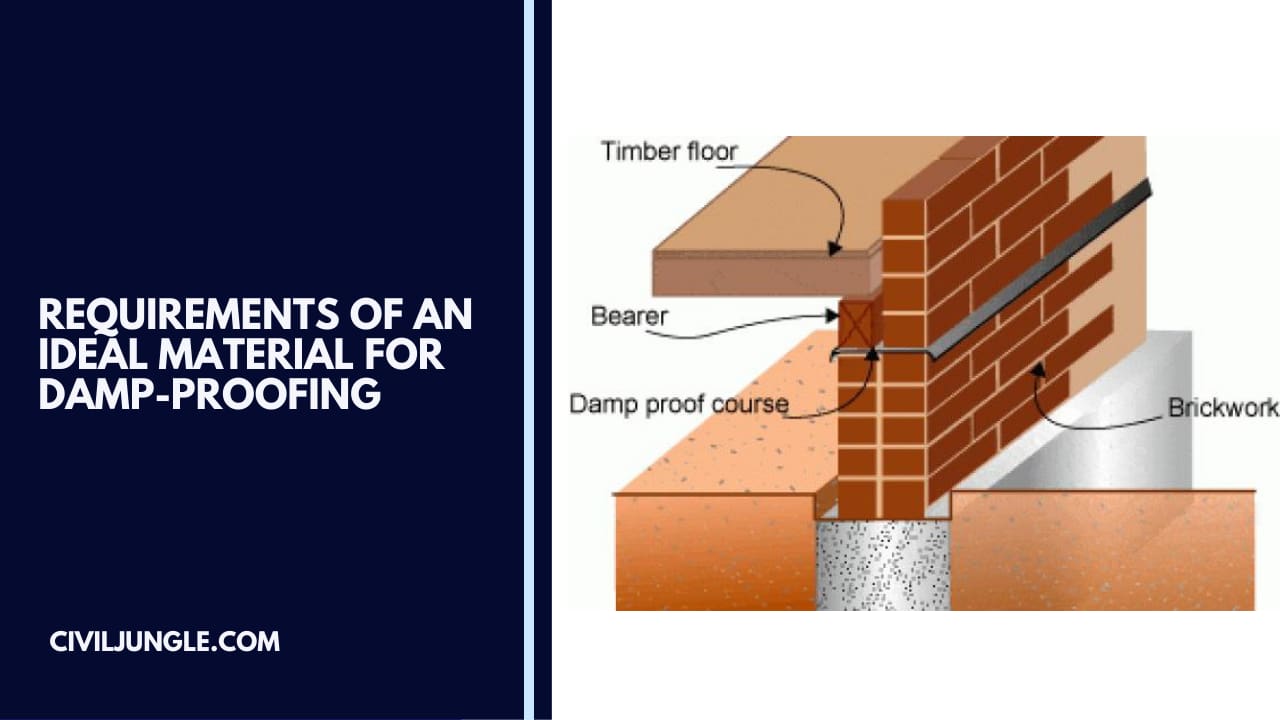

Water can penetrate the masonry through faulty sills, bad workmanship, etc. and hence in buildings, a layer of water repellent material called damp proof course (DPC) is introduced, which acts as a barrier against the capillary rise of water.

Requirements of an Ideal Material for Damp-Proofing

Following are the requirements of an ideal material for damp-proofing:

- Damp Proofing material should be durable.

- It material should be dimensionally stable.

- Material should be reasonably cheap.

- The material should be free from sulfates, chlorides, and nitrates.

- The material should be such that it remains steady and does not allow any movement n itself.

- The material should be perfectly impervious.

- The material should be capable of resisting safely the loads coming on it.

- The material should be flexible so that it can adjust the structural movements without any fracture.

Also, read: What Is Quarrying of Stones | Methods of Quarrying | Selection of a Site for Quarrying of Stones

Materials Used for Damp-Proofing

Following are the materials which are commonly used for the damp-proofing:

- Hot Bitumen

- Mastic Asphalt

- Bituminous Felts

- Metal Sheets

- Combination of Sheets and Felts

- Stones

- Bricks

- Mortar The mortar

- Cement Concrete

- Plastic Sheets

1. Hot Bitumen

This is a flexible material and is placed on the bed of concrete or mortar. This material should be applied with a minimum thickness of 3 mm.

Also, read: Different Between Clamp Burning and Kiln Burning | What Is Clamp Burning | What IS Kiln Burning

2. Mastic Asphalt

This is a semi-rigid material, and it forms an excellent impervious layer for damp-proofing. The asphalt is a very durable and completely impervious material.

It can withstand only very slight distortion. It is liable to squeeze out in very hot climates or under very heavy pressure.

3. Bituminous Felts

This is a flexible material. It is easy to lay and is available n rolls of normal wall width. It is laid on a layer of cement mortar.

An overlap of 100 mm is provided at the joints, and full overlap is provided at all corners. The laps may be sealed with bitumen, if necessary.

The bitumen felt can accommodate slight movements. But it is liable to squeeze out under heavy pressure, and it offers little resistance to sliding.

The material is available in rolls, and it should be carefully unrolled, especially in cold weather.

4. Metal Sheets

The sheets of lead, copper, and aluminum can be used as the membranes of damp-proofing. The lead is a flexible material. The thickness of lead sheets should be such that its weight is not less than 200 N/m2. The lead can be dressed to complex shapes without fracture, and it possessed high resistance to sliding action.

It is impervious to moisture, and it does not squeeze out under ordinary pressure. It resists ordinary atmospheric corrosion. The surfaces of lead coming in contact by a coating of bitumen or of bitumen paint of high consistency. The copper is a flexible material.

It possesses a higher tensile strength than that of lead. It is impervious to moisture, and it does not squeeze out under ordinary pressure. It possesses high resistance to sliding action. The external walls, especially of stones, are likely to be stained when a damp-proof course of copper is adopted.

The surface of copper coming Ja contact with mortars are likely to be affected. But, for normal use, the metal does not require any protective coating. The aluminum sheets can also be used for damp-proofing. But they should be protected with a layer of bitumen.

Also, read: Definition Related for Plastering Work | Tools For Plastering | Preparation of Background for Plastering

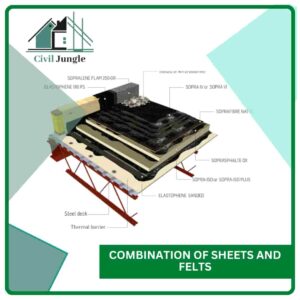

5. Combination of Sheets and Felts

A lead foil is sandwiched between asphalt or bituminous felt. This is known as the lead core, and it is found to be economical, durable, and efficient.

6. Stones

The two courses of sound and dense stones such as granites, slates, etc. laid in cement mortar with vertical breaking joints can work as an effective damp-proofing course.

The stones should extend for full width of the wall. Sometimes the stones can be fixed as .n case of a roof surface, on the exposed faces of the wall, etc.

7. Bricks

The dense bricks, absorbing water less than 4.50% of their weight, can be used for damp-proofing at places where the dampness is not excessive.

The joints are kept open. Such bricks are widely used when a damp-proofing course is to be inserted in an existing wall.

Also, read: Difference Between Lime and Cement | What Is Lime (Hydraulic) | What Is Cement

8. Mortar

The mortar to be used for bedding layers can be prepared by mixing 1 part of cement and 3 parts of sand by volume. A small quantity of lime is added to increase the workability.

For plastering work, the water-proof mortar can be prepared. It is prepared by mixing 1 part of cement, 2 part of sand and pulverized alum at the rate of 120 N / m3 of sand.

In the water to be used, 0.75 N of soft soap is dissolved per liter of water, and this soap water is then added to the dry mix. The mortar thus prepared is used to plaster the surface.

Alternatively, some patented water-proofing material such as Pudlo, Cido, Dempro, etc. may be added to the cement mortar.

9. Cement Concrete

A cement concrete layer in the proportion 1: 2: 4 is generally provided at the plinth level to work as a damp-proofing course.

The depth of cement concrete layer varies from 40 mm to 150 mm. It stops the rise of water by capillary action, and it is found to be effective at places where the dampness is not excessive.

10. Plastic Sheets

The material is made of black polythene, having a thickness of about 0.50 mm to 1 mm with the usual width of wall, and it is available in roll lengths of 30 m. this treatment is relatively cheap, but it is not permanent.

What Is Dampness?

Dampness refers to the presence of excess moisture or water in an environment or material. It is a condition where there is a higher level of moisture than what is considered normal or desirable. Dampness can occur in various places, such as buildings, basements, walls, and even outdoor spaces.

What Is Dampness in Building?

Structural dampness is the presence of unwanted moisture in the structure of a building, either the result of intrusion from outside or condensation from within the structure. A high proportion of damp problems in buildings are caused by ambient climate dependent factors of condensation and rain penetration.

What Causes Dampness in Walls?

Poor ventilation is one of the main causes of dampness as a lot of moisture is generated while washing clothes, cooking or drying clothes within the indoors. Water from the leaky plumbing lines of the exteriors or interiors can result in damp walls.

Damp Proofing Materials

- Hot bitumen. This is a malleable substance that is applied to concrete or mortar beds.

- Mastic Asphalt. It is a semi-rigid substance that produces an effective damp-proofing impermeable

- layer.

- Bituminous Felt.

- Bricks.

- Mortar.

- Stones.

Damp Proofing Materials for Walls

There are several damp-proofing materials available for walls to prevent or mitigate dampness. The choice of material depends on the specific cause of dampness and the extent of the problem. Here are some common damp-proofing materials used for walls

- Damp-proof Membrane (DPM)

- Liquid Damp-proofing Coatings

- Cementitious Tanking

- Cavity Wall Insulation

Damp Proof Material

Cavity Wall Insulation: While not specifically a damp-proofing material, cavity wall insulation can help reduce moisture transfer through walls. Insulating materials, such as mineral wool or foam, are inserted into the cavity between the inner and outer walls. This insulation can prevent condensation and dampness caused by temperature differentials.

Types of Damp Proofing Materials

Materials widely used for damp proofing include: Flexible materials like butyl rubber, hot bitumen (asphalt), plastic sheets, bituminous felts, sheets of lead, copper, etc.

Hot Bitumen for Damp Proofing

Hot bitumen or hot asphalt

Bitumen or asphalt forms an excellent damp-proof course, as it offers an impervious, indestructible and tough surface.

Most Commonly Used Damp Proofing Material

Common materials used for damp proofing include bitumen, polyethylene sheeting, and plastic membranes. Bitumen is applied to the surface of concrete and masonry walls to create a waterproof seal.

Dpc Full Form in Civil Engineering

A damp-proof course (DPC) is a barrier through the structure designed to prevent moisture rising by capillary action such as through a phenomenon known as rising damp.

Materials Used for Dpc

Materials used for DPCs

- Bitumen roll.

- Slates and cement mortar.

- Mastic asphalt.

- Lead or copper sheeting.

- Tar and pitch.

Following Stone Is Suitable for Damp Proofing

Slate is another stone that has low porosity, making it resistant to water absorption. It can be an effective choice for damp-proofing, particularly when used as a cladding material or for roofing.

A Flexible Material Used for Dpc Is

Estimation of D.P.C work is performed/measured in square meters of area. Materials widely used for damp proofing other than concrete include: Flexible materials like butyl rubber, hot bitumen (asphalt), plastic sheets, bituminous felts, sheets of lead, copper, etc.

Like this post? Share it with your friends!

Suggested Read –

- Big Roofing Companies

- West Point Bridge Designer

- What Is Plaster | Type of Plaster | Defects In Plastering

- Introduction of USCS | USCS Classifies Soils into Two Broad Categories

- Introduction of Gantry Girder | Load on Gantry Gutter | Type of Load on Gantry Gutter

- What Is Pier Foundation | Types of Drilled Piers | Advantages and Disadvantages of Drilled Pier Foundations

Originally posted 2023-05-17 17:00:46.

Leave a Reply