Introduction of Signs of Bad Concrete Pour

Important Point

Concrete is one of the most widely used building materials in our construction industry. It is very important that concrete should be pulled into the mould with proper precaution and care otherwise, we will not get the desired strength of concrete.

In this article, we will highlight the Signs of Bad concrete pour and the methods which should be used to treat the defects of the concrete.

What Is Concrete?

Concrete is a composite material that is manufactured cement, fine aggregate (sand), coarse aggregate ( gravels), and water in an appropriate proportion. Cement act as a binding material in concrete and aggregates acts as a filler material.

While manufacturing concrete the different materials are mixed properly in a specific proportion to obtain the concrete with desired strength.

Concrete is a uniform mixture of cement, sand, aggregate, and water in the prescribed proportion which sets and hardens and acquired the desired strength over a certain period.

The concreting operation consists of measuring the ingredients, mixing them properly to obtain a uniform mixture, and placing the concrete in the moulds which are known as formwork.

Concrete is compacted and allows to set and hardened. It is very necessary that concrete should be cured for about 28 days by keeping it constantly moist.

- Concrete Construction Tools for Construction Sites

- What Is Concrete | 31 Different Types of Concrete

- What Is Hardened Concrete | Properties of Hardened Concrete

- What Is Spalling Concrete | Causes of Spalling in Concrete | Repairing Concrete Spalding

- 8 Different Methods of Concrete Crack Repair | How to Select Suitable Method of Concrete Crack Repair

- What Is Honeycomb In Concrete | Cause of Honeycomb In Concrete| Cure of Honeycomb In Concrete | Types of Grouting

Uses of Concrete

Concrete has various uses in the construction sectors which are as follows.

- Concrete is generally used in the construction of roads and bridges.

- Concrete is used in the construction of the electric poles.

- Concrete is widely used in the construction of high-rise buildings.

- It is also used various types of flooring.

- Concrete is used in the construction of sidewalks and driveways.

- Concrete is a very important building material that is used for the construction of various residential as well as commercial projects.

- Concrete is also used in the construction of foundations and basements.

- Concrete is used in the casting of beams and columns.

- Concrete is used in the construction of culverts and sewers.

- Why Hairline Cracks in Concrete | Types of Cracks in Concrete

- What Is Concrete Topping | Topping Slab Definition | Types of Topping Slab | Advantages & Disadvantage of Topping Slab

- What Is a Concrete Mixer | Types of Concrete Mixer | Specifications of the Concrete Mixer | How to Mix Concrete in a Mixer

- What Is Concrete Screed | Concrete Screed Specifications | Characteristics of Concrete Screed | Advantages & Disadvantages of Concrete Screed

- What Is Modulus of Rupture | What Is Flexural Modulus | What Is Flexural Stress | Flexural Strength of Concrete | Bending Modulus | What Is Flexural Strength

Signs of Bad Concrete Pour

The signs of bad concrete pour are classified into mainly two types.

- Signs of Bad Concrete Pour during concreting

- Signs of Bad Concrete Pour after Hardening of concrete

There are various signs of bad concrete pour on the structure which are as follows

Signs of Bad Concrete Pour During Concreting

List of Bad concrete signs time of pour during the concrete are as follows.

- Bleeding.

- Segregation.

- Spalling of Concrete.

- Cracking of concrete.

- Scaling of Concrete.

- Honeycombing of concrete.

- Alkali Aggregate Reactions in Concrete.

- Crazing.

- Delamination of Concrete.

- Dusting.

1. Signs of Bad Concrete: Bleeding

The Bleeding of concrete is a Phenomenon in which free water in the concrete mix rises up or comes on the surface of the concrete layer of cement slurry. The bleeding is a sign of Bad Concrete Pour.

Bleeding is accepted at a certain limit, but excessive bleeding in the concrete can reduce the strength of the concrete. The bleeding in the concrete occurs when the coarse aggregates present in the concrete gets to settle down and the free water present in the concrete comes on the surface of the concrete.

The one of the main reason which causes bleeding in concrete is an improper water-cement ratio. The greater water-cement ratio leads to excessive bleeding in the concrete.

Due to the bleeding concrete loses its strength and homogeneity. Bleeding causes permeability in the concrete. In the process of bleeding the water gets accumulated and it develops air voids in the concrete which reduces the bond between cement and aggregate.

The bleeding will not cause major harm if the rate of evaporation of the water is equal to the rate of bleeding in the concrete. The normal bleeding is quite good property of the concrete because it will improve the workability of the concrete.

Methods to Reduce Bleeding in Concrete

The following method should be used during concreting to reduce bleeding in concrete.

- Add a very less amount of water content in the mix of the concrete or use chemical admixtures to show that demand for water gets reduced and required workability is also achieved.

- Design the concrete mix properly add more amount of cement in the concrete mix.

- Proper measure and method of mixing should be used to reduce bleeding in the concrete.

Also, Read: What Is Glass Fiber Reinforced Gypsum | Applications of GFRG | Disadvantages of The GFRG Panel

2. Signs of Bad Concrete: Segregation

Segregation of concrete is defined as the separation of the cement paste from the aggregate during the placing and handling of the concrete on the construction site. Aggregation is one of the major signs of Bad concrete pour.

Segregation occurs when the concrete is over vibrated or compacted during concreting work. Segregation will affects the strength and the durability of the concrete.

The causes of segregation of concrete is due to the use of high water-cement ratio in the mixing of concrete. Excessive vibration during concreting can also lead to the problem of segregation.

The primary cause of segregation in the concrete is due to there variation in the specific gravity of different materials used in the manufacturing of concrete.

When the concreting operation is done from a larger height in the case of underground foundations, it will need to the secretion of concrete which is a bad sign of concrete pour.

It is necessary that segregation of the concrete should be prevented to achieve the desired strength and the quality of the concrete in the construction of the structure. During the concreting, the depth should not be more than 1.5 m.

The segregation of the concrete can be also minimised by adding air-entraining agents and admixtures in the concrete and maintaining proper proportioning of the design mix. Signs of bad concrete poor after Hardening of the concrete.

3. Signs of Bad Concrete: Spalling of Concrete

Spalling is the phenomenon in which an area of concrete gets cracked and delaminated from the substrate. spalling of the concrete leaves the concrete surface patchy and exposed aggregate.

Spalling in the concrete when the large area of the concrete separates or removes from the concrete member. The spalling defect are very similar to the scaling of the concrete in which flakes break loose from the concrete.

Spalling is a sign of bad concrete that affects the concrete structures and their durability. Causes of spalling of the concrete due to the expansive effect of alkali-silica reactions and the use of improper cover.

Effect of Spalling of the concrete is categorized into various forms as per its intensity.

- Light: When the detected area of the concrete measures less than 150 mm in any direction or less than 25 mm in depth. This will be considered as a light spalling of concrete.

- Medium: When the defected area concrete measures between 150mm to 300mm in any direction or between 25mm and 50mm in depth. This will be considered as a medium spalling of concrete.

- Severe: When the defected area of concrete measures between 300mm to 600mm in any direction or between 50mm and 100mm in depth. It will be considered as severe spalling of concrete.

- Very severe: When the defected area of the concrete more than 600 mm in any direction or greater than 100 mm in depth. This will be considered as the very severe spalling of concrete.

Also, Read: How to Calculate Slab Steel Quantity from Drawing | BBS of Slab

4. Signs of Bad Concrete: Cracking of Concrete

Cracking is one of the commonly observed and major defect occurred in the concrete. A crack in concrete is a fine fracture that extends partly or completely through the member.

The Tensile stresses which are developed in the concrete members are one of the major reason which causes cracking in the concrete.

5. Signs of Bad Concrete: Scaling of Concrete

The scaling of concrete generally occurs when the loss of surface portion of the concrete due to freezing or deterioration of concrete. The scaling of concrete is generally observed in air-entrained concrete.

The scaling of concrete mainly occurs in the poorly finished surface of the concrete. Scaling is a bad sign of concrete that affects the appearance of the surface of the concrete.

The range of scaling of the concrete categorized are as follows.

- Light: The light scaling of the concrete occurs When there is a Loss of surface mortar up to 5mm depth without any exposure of coarse aggregates.

- Medium: The medium scaling of the concrete occurs When there is a Loss of surface mortar up to 6 to 10 mm depth with exposure of some coarse aggregates.

- Severe: The severe scaling of the concrete occurs when there is a loss of surface mortar up to 11 mm to 20 mm with aggregate particles standing out from the concrete.

- Very Severe: The very severe scaling of the concrete occurs when there is a loss of mortar and aggregate particles to a depth greater than 20 mm.

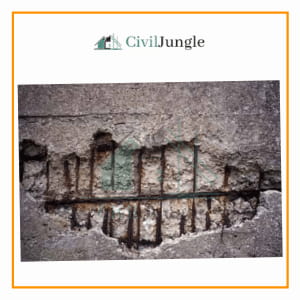

6. Signs of Bad Concrete: Honeycombing of Concrete

Honeycombing of the concrete sign of bad concrete which generally occurs due to the improper compaction for vibration of the concrete during placing and compacting the concrete on the construction site.

The honeycombing of the concrete develops voids in the concrete due to which the concrete loses its compressive strength.

Honeycombing of Concrete is measured in a different range which are as follows.

- Light: The honeycombing of the concrete up to a depth less than 25mm.

- Medium: Honeycombing of the concrete ranges to a depth between 25mm and 50mm.

- Severe: Honeycombing of a concrete range to a depth between 50 mm and 100 mm.

- Very Severe: Honeycombing of the concrete to a depth greater than 100 mm.

Also, Read: Top 15+ Best Plywood Brands in India

7. Signs of Bad Concrete: Alkali Aggregate Reactions in Concrete

A chemical attack on concrete can occur if aggregates are alkaline and chemically reactive. concrete can be attacked by different chemically active matters like acids, some alkalis, various salt solutions, and organics such as sugars, and animal oils, especially if they contain free acids. It is signs of bad concrete.

Aggregates present in the concrete are alkaline and chemically reactive, it will cause an alkali-aggregate reaction in concrete. The alkali-aggregate reaction will affect the durability and appearance of the concrete

To prevent the alkali-aggregate reaction use low alkali cement in the concrete and also reduce the moisture and maintained the concrete in a dry state.

Also, Read:

8. Signs of Bad Concrete: Crazing

Crazing is a defect that occurs on the surface of the concrete and forms a map pattern of fine cracks. The cracks extend only through the surface layer. This is due to minor surface shrinkage as a result of dry conditions.

The problem of creating can be prevented by proper finishing and curing of the concrete as soon as possible. These types of cracks do not harm the concrete structure. It will affect the appearance of the structure.

9. Signs of Bad Concrete: Delamination of Concrete

The delamination of the concrete is the separation of the concrete surface for a layer that is substantially separated but not completely detach from the concrete element.

Delamination of the concrete is a bad sign of concrete which will affect the durability of the structure. The performance of the concrete get reduced gradually due to delamination of the concrete.

The delamination of the concrete can be prevented by finishing the surface of the slab after the process of bleeding starts.

Also, Read: Precipitation | Type of Precipitation | Cyclonic Precipitation

10. Signs of Bad Concrete: Dusting

Dusting is the surface defect that appears as a fine powder on the surface of the concrete. The fine powder will come off when the brushed the surface of the concrete. The dusting is due to the finishing of the concrete before bleed water has dried out.

Dusting can also cause due to inadequate curing of the concrete. It can be repaired by applying a chemical floor hardener or a bonded topping.

Conclusion of Signs of Bad Concrete

The spalling of concrete, Honeycombing, cracking of the concrete surface, bleeding, crazing, dusting, scaling of the concrete and delamination of concrete are the signs of bad concrete pour.

All the defects must be treated properly otherwise it will cause major harm to the structures and affects the durability of the concrete.

Types of Concrete Defects

Different types of defects in concrete structures can be cracking, crazing, blistering, delamination, dusting, curling, efflorescence, scaling and spalling. These defects can be due to various reasons or causes.

What Are the Defects in Concrete?

- Freeze-Thaw Effect.

- Chemical Attack.

- Crazing.

- Scaling.

- Blisters.

- Spalling.

- Dusting.

How Can You Tell If Concrete Is Defective?

Common signs of bad concrete pouring.

- Bleeding.

- Delamination.

- Honeycombing.

- Cracking.

- Spalling.

Which One Is the Defect in Hardened Concrete?

Crazing occurs due to rapid hardening of a top surface of concrete due to high temperatures or if the mix contains excess water content or due to insufficient curing.

What Are the Factors Affecting the Durability of Concrete?

- Cement Content.

- Aggregate Quality.

- Water Quality.

- Concrete Compaction.

- Curing Period.

- Permeability.

- Moisture.

- Temperature.

Pouring Concrete and Rain

Pouring Concrete in Rain. Pouring concrete in the rain can compromise its strength, increasing the tendency for dusting and scaling to develop. Once the damage is done, it can be hard to rectify and will often ruin the appearance of the finished surface. Don’t let it rain on your parade.

Signs of a Bad Contractor

- They constantly make excuses.

- They have significantly lower prices than competitors.

- They don’t like written agreements.

- They only communicate via phone calls.

- They don’t answer your questions.

- They’re not comfortable providing you with references.

- They are unlicensed.

How to Fix a Bad Concrete Job?

In most cases, a poor concrete job cannot be saved; the slab should be removed and a new one poured in its place. If the visible finishing was done poorly then you can assume there are other hidden problems that will soon appear.

Can Concrete Be Poured on Top of Concrete?

If the existing concrete is in good shape structurally, you can pour new concrete over it to freshen it up. Worn or cracking concrete makes your outdoor areas look drab, outdated, and in need of fresh concrete. … If the existing concrete is in good shape structurally, you can pour new concrete over it to freshen it up.

Is It Ok to Pour Concrete in the Rain?

Pouring Concrete in Rain. Pouring concrete in the rain can compromise its strength, increasing the tendency for dusting and scaling to develop. Once the damage is done, it can be hard to rectify and will often ruin the appearance of the finished surface. Don’t let it rain on your parade.

What Causes Concrete Scaling?

Concrete slabs exposed to freezing and thawing in the presence of moisture and/or deicing salts are susceptible to scaling. Most scaling is caused by the Application of excessive amounts of calcium or sodium chloride deicing salts on concrete with inadequate strength, air entrainment, or curing.

Cracks in Concrete Slab Normal

A crack in a slab of 1/8 inch or less is typically a normal shrinkage crack and not a cause for concern. If the crack is larger or growing larger (an “active” crack), or one side of the crack is higher than the other, then you may need to have the work reviewed by a structural engineer.

What Causes Concrete to Harden?

The water causes the hardening of concrete through a process called hydration. Hydration is a chemical reaction in which the major compounds in cement form chemical bonds with water molecules and become hydrates or hydration products. Aggregates are chemically inert, solid bodies held together by the cement.

Like this post? Share it with your friends!

Suggested Read –

- Top 10 Tiles Companies in India 2021

- How to Building Construction Process Step by Step

- 81 Nos of List Use Construction Tools and Pieces of Equipment

- What Is DLC (Dry Lean Concrete) | Advantage of DLC (Dry Lean Concrete)

- What Is Camber in Road | Types of Camber | Advantages of Camber in Road

- Estimation for Building Works | Centre Line Method | Long and Short Wall Method

- Density of Cement Sand and Aggregate | Cement Density | Sand Density | Aggregate Density | list of Density

- Standard Brick Size & Weight | Standard Brick Size With Shape | Brick Types & Specification Based on Application

- What Is Shear Wall | Classification of Shear Walls |Advantages of Shear Wall | Functions of Shear Wall | Important Point Shera Wall

- What Is Pneumatic Structures | Types of Pneumatic Structures | Advantages & Disadvantages of Pneumatic Structures | Uses of the Pneumatic Structures

Originally posted 2022-04-06 18:05:20.

Leave a Reply