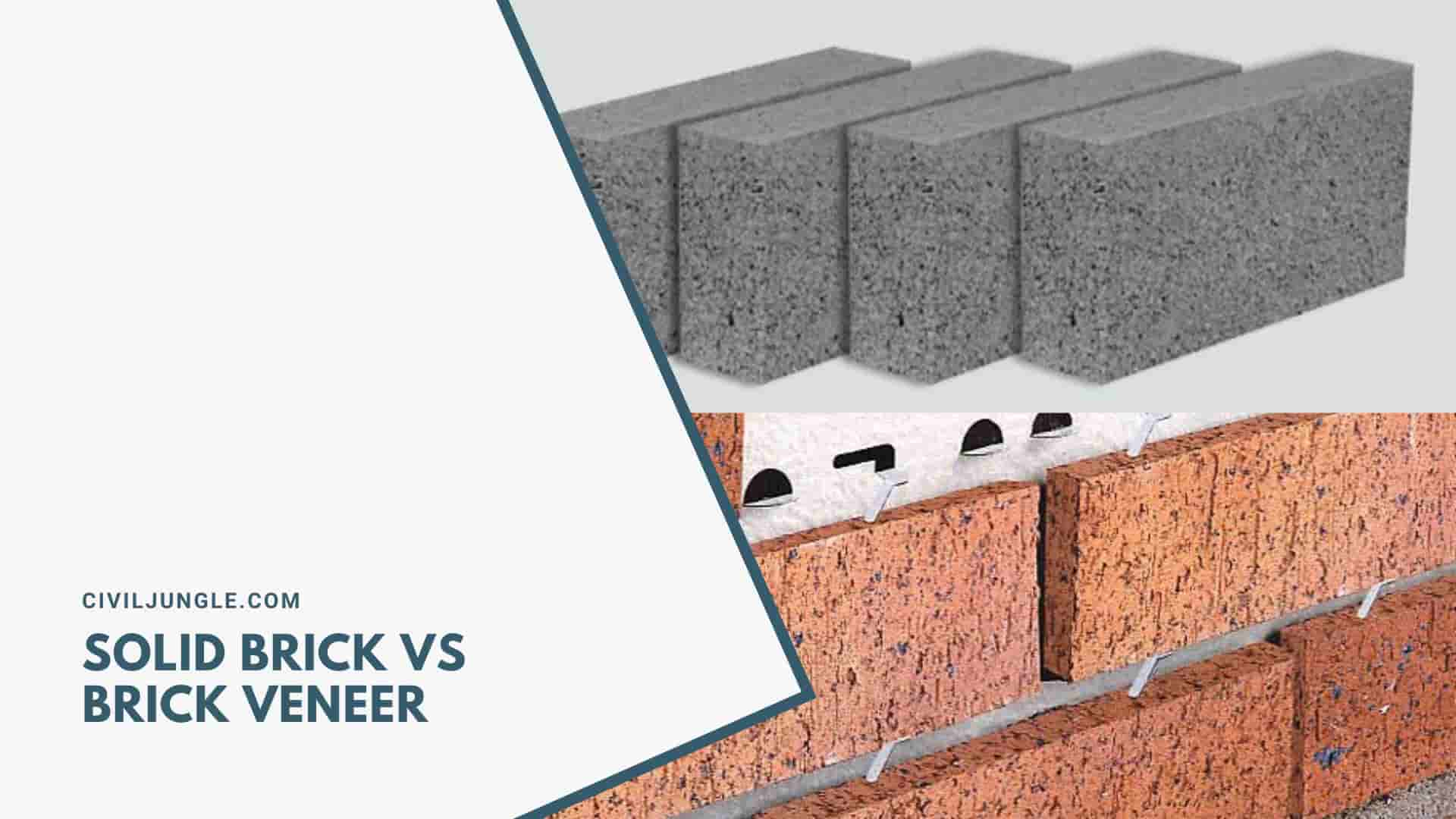

Solid Brick vs Brick Veneer

Important Point

When it comes to building a new home or renovating an existing one, one of the key decisions is choosing between solid brick and brick veneer.

While both have their advantages and disadvantages, the choice between the two depends on a number of factors, including budget, climate, and aesthetic preferences.

In this article, we will compare solid brick and brick veneer in terms of their construction, insulation, durability, and cost, to help you make an informed decision.

1. Construction of Solid Brick vs Brick Veneer

Solid Brick

- Solid brick walls are made of bricks stacked on top of each other, with mortar in between.

- The bricks are usually 230mm wide and have a depth of 110mm, making the wall 300mm thick.

- This creates a solid, load-bearing structure that can support the weight of the building.

- Solid brick walls can be left exposed or covered with plaster, render, or cladding.

Brick Veneer

- Brick veneer, on the other hand, consists of a single layer of bricks that is attached to a timber or steel frame.

- The frame is then covered with a waterproof membrane, insulation, and plasterboard on the inside, and the brick veneer is attached to the outside.

- The bricks used for the veneer are usually thinner than those used for solid brick walls, around 75mm to 100mm thick.

- This means that the wall is only around 110mm to 140mm thick, depending on the thickness of the insulation used.

2. Solid Brick vs Brick Veneer for Insulation

Solid Brick

- One of the key differences between solid brick and brick veneer is their insulation properties.

- Solid brick walls have good thermal mass, which means that they can absorb and store heat from the sun during the day and release it slowly at night.

- This helps to regulate the temperature inside the building, keeping it cooler in summer and warmer in winter.

- However, solid brick walls do not have great insulation properties and can be quite drafty if not properly sealed.

Brick Veneer

- Brick veneer, on the other hand, offers better insulation than solid brick walls.

- The cavity between the brick veneer and the internal wall can be filled with insulation, which helps to keep the building warm in winter and cool in summer.

- This makes brick veneer a more energy-efficient option, which can save you money on heating and cooling costs in the long run.

3. Solid Brick vs Brick Veneer: Durability

Solid Brick

- Both solid brick and brick veneer are durable and long-lasting building materials.

- Solid brick walls are extremely strong and can withstand high winds and heavy rain.

- They are also resistant to fire and pests, which makes them a good choice for areas prone to bushfires or termite infestations.

- However, solid brick walls are susceptible to cracking if the ground beneath them shifts or settles.

Brick Veneer

- Brick veneer is also durable and can withstand harsh weather conditions.

- However, it is not as strong as solid brick walls and can be damaged by impacts, such as from a falling tree branch or hail.

- In addition, the waterproof membrane that is used to protect the internal wall can deteriorate over time, which can lead to moisture problems and mold growth.

4. Solid Brick vs Brick Veneer: Cost

Solid Brick

- The cost of building with solid brick or brick veneer depends on a number of factors, including the size of the building, the type of bricks used, and the complexity of the design.

- In general, solid brick walls are more expensive than brick veneer walls because they require more materials and labor to construct.

Brick Veneer

- Brick veneer is a more affordable option, as it requires fewer bricks and less labor to install.

- However, the cost of insulation and the waterproof membrane should be factored in, as these are necessary components of a brick veneer wall.

- In addition, if the internal wall is not load-bearing, a timber or steel frame will need to be installed, which can add to the cost.

Useful Article for You

- Gable Vs Hip Roof

- Screw Vs Bolt

- Truss Vs Rafter

- Mortar Vs Concrete

- Nail Vs Screw

- Live Load Vs Dead Load

- Grout Vs Mortar

- H Beam Vs I Beam

- Cinder Block Vs Concrete Block

- Tension Vs Compression

- Timber Vs Lumber

- Fender Washer Vs Flat Washer

- Footing Vs Foundation

- Azimuth Vs Bearing

- Silt Vs Clay

- Hempcrete Vs Concrete

- Curtain Vs Drapes

- Luminous Flux Vs Lumens

- Knee Wall Vs Pony Wall

- Theodolite Vs Transit

- Black Water Vs Grey Water

- Construction Joint Vs Control Joint

- Stem Wall Vs Monolithic Slab

- Coarse Grained Vs Fine Grained

- Pier Vs Pile

- Grade Beam Vs Footing

- Mortar Cement Vs Masonry Cement

- Quikrete Vs Concrete

- One Way Slab Vs Two Way

- Load Bearing Vs Non Load Bearing

- Fence Post Anchors Vs Concrete

What Is Solid Brick?

Solid brick, also known as full brick or double brick, is a building material that has been used for centuries in construction.

It is made of bricks that are stacked on top of each other and held together with mortar.

The result is a solid, load-bearing structure that is strong, durable, and fire-resistant.

In this article, we will explore the history of solid brick, its properties, and its uses in modern construction.

History of Solid Brick

The use of brick as a building material dates back to ancient civilizations such as the Egyptians, who used sun-dried bricks made from mud and straw.

The use of fired bricks, which are stronger and more durable than sun-dried bricks, can be traced back to the Indus Valley Civilization in India around 3000 BCE.

From there, the use of brick spread to other parts of the world, including Mesopotamia, Greece, and Rome.

Solid brick construction became popular in Europe during the Middle Ages when castles and other fortifications were built using thick walls made of stone or brick.

Solid brick was also used in the construction of churches and other religious buildings, as well as houses and public buildings.

In the 19th and early 20th centuries, solid brick was the dominant building material in many parts of the world, including Australia, New Zealand, and the United Kingdom.

It was used to construct everything from small cottages to large commercial buildings and public structures.

However, with the advent of new building materials and techniques, such as reinforced concrete and steel framing, solid brick construction began to decline in popularity.

Properties of Solid Brick

Solid brick is a strong and durable building material that offers a number of benefits over other types of construction.

Some of its key properties include:

- Load-bearing: Solid brick walls are capable of supporting the weight of the building without the need for additional support structures. This makes them ideal for buildings with multiple stories or large open spaces.

- Fire-resistant: Bricks are made of clay that has been fired at high temperatures, which gives them excellent fire resistance. Solid brick walls are capable of withstanding high temperatures for extended periods of time, which can help to contain fires and prevent them from spreading.

- Insulating: Solid brick walls have good thermal mass, which means that they can absorb and store heat from the sun during the day and release it slowly at night. This helps to regulate the temperature inside the building, keeping it cooler in summer and warmer in winter. However, solid brick walls do not have great insulation properties and can be quite drafty if not properly sealed.

- Durable: Solid brick is a long-lasting building material that is resistant to weathering, erosion, and pests such as termites. It requires little maintenance and can last for centuries if properly cared for.

Uses of Solid Brick

Solid brick is a versatile building material that can be used in a wide range of applications.

Some of its common uses include:

- Residential construction: Solid brick is often used to construct houses and other residential buildings. It is popular for its strength, durability, and fire resistance, as well as its aesthetic appeal.

- Commercial construction: Solid brick is also used in the construction of commercial buildings, such as offices, retail spaces, and warehouses. It is valued for its load-bearing capacity, fire resistance, and insulation properties.

- Public buildings: Solid brick is often used in the construction of public buildings, such as schools, hospitals, and government offices. It is valued for its durability and fire resistance, as well as its ability to provide a sense of solidity and permanence.

- Restoration: Solid brick is often used in the restoration of historic buildings and landmarks.

What Is Brick Veneer?

Brick veneer is a building material that is often used as an alternative to solid brick construction.

It is a thin layer of brick that is applied to the exterior of a building, giving the appearance of a solid brick wall.

In this article, we will explore the history of brick veneer, its properties, and its uses in modern construction.

Useful Article For You

- What Is a Contour Interval

- What Is a Spread Footing

- What Is a Flight of Stairs

- What Is a Pitched Roof

- What Is a Parapet

- What Are Abutments on a Bridge

- What Is Grouting

- What Is Gypsum Board

- What Is Cmu in Construction

- What Is Flooring

- What Are Tiles

- What Is Modulus of Rupture

- What Is Rcc Value Day

- What Is Rebar

- What Is Soffit

History of Brick Veneer

The use of brick veneer as a building material dates back to the early 20th century, when it was developed as a way to reduce the cost of construction.

At that time, solid brick was the dominant building material in many parts of the world, but it was expensive and time-consuming to install.

Brick veneer offered a more affordable and efficient alternative, while still providing the aesthetic appeal of solid brick construction.

Brick veneer was initially used in residential construction, particularly in areas where solid brick was not readily available or affordable.

It soon gained popularity in commercial construction as well, particularly in urban areas where space was limited and construction costs were high.

Properties of Brick Veneer

Brick veneer has a number of properties that make it an attractive building material for many applications. Some of its key properties include:

- Cost-effective: Brick veneer is generally less expensive than solid brick construction, making it an affordable option for many builders and homeowners.

- Lightweight: Brick veneer is much lighter than solid brick, which makes it easier to transport and install. This can also reduce the amount of structural support needed for the building.

- Versatile: Brick veneer can be applied to a wide range of building materials, including wood, concrete, and steel. This makes it a versatile option for many different types of construction projects.

- Aesthetically pleasing: Brick veneer gives the appearance of a solid brick wall, which is often considered more attractive than other types of construction materials.

- Energy-efficient: Brick veneer has good insulation properties, which can help to reduce energy costs and improve the comfort of the building’s occupants.

Uses of Brick Veneer

Brick veneer is a versatile building material that can be used in a wide range of applications. Some of its common uses include:

- Residential construction: Brick veneer is often used in the construction of houses and other residential buildings. It can be used as a complete exterior finish or as an accent material to complement other building materials.

- Commercial construction: Brick veneer is also used in the construction of commercial buildings, such as offices, retail spaces, and restaurants. It is often used as an accent material to add visual interest to the building’s exterior.

- Public buildings: Brick veneer is often used in the construction of public buildings, such as schools, libraries, and government offices. It can be used to give the building a sense of solidity and permanence, while also providing energy-efficient insulation.

- Renovation and restoration: Brick veneer can be used in the renovation and restoration of older buildings. It can be used to replace damaged or deteriorating brickwork or to add visual interest to the building’s exterior.

Installation of Brick Veneer

The installation of brick veneer typically involves the following steps:

- Preparation of the substrate: The substrate, which is the surface to which the brick veneer will be applied, must be clean, level, and free of debris. This may involve the use of a pressure washer or other cleaning equipment.

- Installation of the moisture barrier: A moisture barrier, such as a layer of tar paper or house wrap, is installed over the substrate to prevent water from penetrating the building.

- Installation of the metal lath: A metal lath is installed over the moisture barrier to provide a surface for the mortar to adhere to.

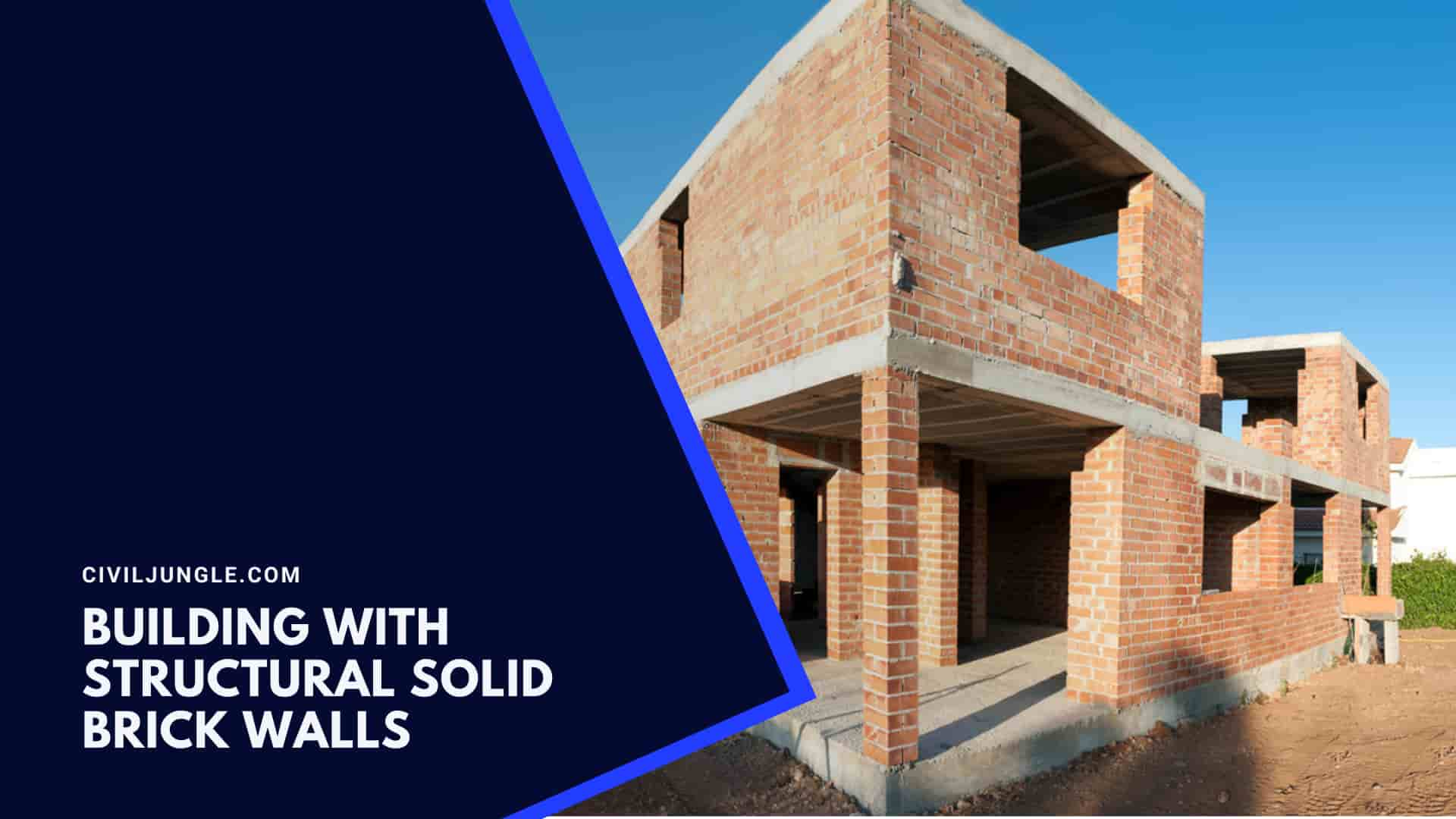

Building With Structural Solid Brick Walls

Structural solid brick walls have been used in construction for thousands of years, and remain a popular choice today for their durability, strength, and aesthetic appeal.

In this article, we will explore the history of structural solid brick walls, their properties, and their uses in modern construction.

History of Structural Solid Brick Walls

The use of brick as a building material dates back to ancient civilizations such as the Mesopotamians, Egyptians, and Romans.

In these early civilizations, brick was often used to build walls, houses, and other structures due to its durability and strength.

In the Middle Ages, brick production declined in Europe due to the scarcity of fuel for brick kilns.

However, it saw a resurgence in popularity during the Renaissance period, when wealthy patrons began using it as a decorative element in their buildings.

In the 19th century, brick production saw another boom as industrialization led to improvements in brick-making technology.

Brick became a popular building material for factories, warehouses, and other industrial buildings.

Properties of Structural Solid Brick Walls

Structural solid brick walls have a number of properties that make them a desirable building material for many applications.

Some of their key properties include:

- Strength and durability: Brick walls are extremely strong and durable, and can last for hundreds of years with proper maintenance. They are resistant to fire, wind, and other types of damage.

- Thermal mass: Brick walls have high thermal mass, which means they can absorb and store heat. This can help to regulate indoor temperatures and reduce energy costs.

- Aesthetically pleasing: Brick walls have a distinctive look that many people find attractive. They can be left exposed for a rustic look or covered with plaster or other finishes for a more polished appearance.

- Sound insulation: Brick walls provide good sound insulation, which can help to reduce noise levels from outside and between different parts of a building.

Uses of Structural Solid Brick Walls

Structural solid brick walls are used in a wide range of construction applications. Some of their common uses include:

- Residential construction: Brick walls are often used in the construction of houses and other residential buildings. They can be used as load-bearing walls or as a decorative element for exterior or interior walls.

- Commercial construction: Brick walls are also used in the construction of commercial buildings, such as offices, retail spaces, and restaurants. They can be used to create a sense of solidity and permanence and to add visual interest to the building’s exterior.

- Industrial construction: Brick walls are commonly used in the construction of factories, warehouses, and other industrial buildings. They are highly durable and can withstand the wear and tear of heavy machinery and other industrial processes.

- Historical preservation: Brick walls are often used in the restoration and preservation of historic buildings. They can be used to replace damaged or deteriorating brickwork or to maintain the original look and feel of the building.

Installation of Structural Solid Brick Walls

The installation of structural solid brick walls typically involves the following steps:

- Foundation: A strong and stable foundation is essential for building brick walls. The foundation should be level and able to support the weight of the brick walls.

- Wall Construction: Brick walls are typically built using a combination of mortar and brick. The mortar is used to hold the bricks together, while the bricks provide structural support for the wall.

- Structural Support: Structural support is needed for large and tall brick walls. This can be provided by reinforcing steel bars, concrete or steel columns, or other forms of support.

- Finishing: Once the brick walls are in place, they can be finished with plaster or other materials. This can help to improve their appearance and provide additional insulation.

Useful Article For You

- Frost Wall

- What Is Drywall

- Wall Paint Finishes

- Sand Concrete Walls

- Gabion Wall Cost

- What Is a Shear Wall

- Types of Partition Wall

- Alternatives to Drywall

- How to Find Wall load

- Mount TV on Brick Wall

- Disadvantages of Wall Putty

- Weep Holes in Retaining Wall

- Pros and Cons of Sealing Brick

- Bathroom Half Wall Panels

- Long Wall Short Wall Method

- Cost to Repair Drywall Ceiling Water Damage

- How to Cover Concrete Walls in Basement

What Are The Benefits Of Solid Brick Wall Construction?

Solid brick wall construction has many benefits that make it a popular choice in the construction industry. Some of the key benefits of building with solid brick walls include:

- Durability: Solid brick walls are extremely durable and can withstand the test of time. They are resistant to weathering, fire, and pests, and can last for hundreds of years with proper maintenance.

- Energy Efficiency: Solid brick walls have high thermal mass, which means they can absorb and store heat. This helps to regulate indoor temperatures and reduce energy costs by keeping the interior of the building cooler in the summer and warmer in the winter.

- Sound Insulation: Solid brick walls provide good sound insulation, which helps to reduce noise levels from outside and between different parts of the building. This makes them ideal for residential buildings or buildings that require a quiet environment.

- Low Maintenance: Solid brick walls require little maintenance once they are built. They do not need to be painted or treated and can be cleaned easily with water and a mild detergent.

- Fire Resistance: Solid brick walls are highly resistant to fire, which can help to prevent the spread of flames in the event of a fire. This can save lives and property, and can also reduce insurance costs.

- Aesthetically Pleasing: Solid brick walls have a distinctive look that many people find attractive. They can be left exposed for a rustic look or covered with plaster or other finishes for a more polished appearance. They can also be customized with different colors and patterns to match the style of the building.

- Environmentally Friendly: Solid brick walls are made from natural materials and can be recycled at the end of their useful life. They also help to reduce energy consumption and greenhouse gas emissions, which can have a positive impact on the environment.

- Increased Property Value: Solid brick wall construction can increase the value of a property due to its durability, energy efficiency, and aesthetic appeal. This can make it a wise investment for homeowners and developers.

In conclusion, solid brick wall construction has many benefits that make it an attractive choice for building construction.

Its durability, energy efficiency, sound insulation, low maintenance, fire resistance, aesthetic appeal, environmental friendliness, and increased property value make it a smart investment for those looking to build a long-lasting and sustainable building.

How Waterproof Is Brick Veneer?

Brick veneer is a popular choice for building construction due to its durability, aesthetic appeal, and affordability.

However, one of the concerns that people have when it comes to brick veneer is its waterproofing capabilities.

In this article, we will explore the question of how waterproof brick veneer is, and what factors can affect its water resistance.

Brick veneer is a type of construction where a layer of bricks is attached to the exterior of a building, typically over a wooden or metal frame.

The bricks are usually not structural and are instead used as a decorative and protective layer.

The space between the brick veneer and the building’s main structure is filled with insulation and air, which helps to improve the building’s energy efficiency.

Waterproofing is an important consideration when it comes to brick veneer, as water can cause damage to the building’s structure and lead to mold growth, which can be harmful to human health.

There are several factors that can affect the waterproofing of brick veneer, including the type of bricks used, the quality of the installation, and the climate in which the building is located.

What Are The Benefits Of Brick Veneer Vs Solid Brick Construction?

When it comes to building construction, brick is a popular choice due to its durability, aesthetic appeal, and longevity.

However, there are two main methods of brick construction: solid brick and brick veneer.

Both methods have their benefits and drawbacks, and the choice between them depends on a number of factors, including cost, structural requirements, and design preferences.

In this article, we will explore the benefits of brick veneer construction compared to solid brick construction.

1.Brick Veneer Vs Solid Brick Construction: Cost

One of the main benefits of brick veneer construction is that it is typically less expensive than solid brick construction.

This is because brick veneer uses a thinner layer of bricks attached to a wood or metal frame, which reduces the amount of material needed and the cost of labor.

Solid brick construction, on the other hand, requires a thicker layer of bricks to be laid directly on top of each other, which can be more time-consuming and labor-intensive.

In addition, solid bricks are often more expensive than brick veneer due to their higher density and durability.

2. Brick Veneer Vs Solid Brick Construction: Structural Considerations

Another benefit of brick veneer construction is that it can be used in conjunction with other building materials, such as wood or metal frames, to create a strong and stable structure.

This is because the brick veneer is not typically load-bearing, meaning it does not support the weight of the building.

Instead, the frame supports the weight of the building, while the brick veneer provides a decorative and protective layer.

This allows for greater flexibility in the design and construction of the building, as it can be customized to meet the specific needs of the project.

Solid brick construction, on the other hand, is load-bearing and requires a thicker layer of bricks to be laid directly on top of each other.

This provides a high level of structural stability and can be particularly useful in areas prone to earthquakes or high winds.

3. Brick Veneer Vs Solid Brick Construction: Energy Efficiency

Brick veneer construction can also be more energy-efficient than solid brick construction.

This is because the space between the brick veneer and the building’s main structure is filled with insulation and air, which helps to improve the building’s energy efficiency.

Solid brick construction, on the other hand, does not typically include this additional layer of insulation and can be more susceptible to energy loss through the walls. This can result in higher heating and cooling costs for the building.

4. Brick Veneer Vs Solid Brick Construction: Aesthetic Appeal

Both brick veneer and solid brick construction offer a high level of aesthetic appeal, but they do so in different ways.

Brick veneers can be customized to achieve a wide range of styles and finishes, including different colors and textures.

This allows for greater flexibility in the design and aesthetics of the building and can be particularly useful in creating a unique and eye-catching exterior.

Solid brick construction, on the other hand, provides a more traditional and classic look, with a uniform appearance and texture.

5. Brick Veneer Vs Solid Brick Construction: Maintenance and Repairs

Finally, brick veneer construction can be easier and less expensive to maintain and repair than solid brick construction.

This is because individual bricks can be replaced or repaired without having to remove the entire layer, which can be more difficult and time-consuming with solid brick construction.

In addition, the space between the brick veneer and the building’s main structure allows for easier access to plumbing and electrical systems, which can be important in the event of maintenance or repairs.

In summary, both brick veneer and solid brick construction offer a range of benefits and drawbacks, and the choice between them depends on a number of factors, including cost, structural requirements, and design preferences.

While brick veneer construction is typically less expensive, more flexible in design, and more energy-efficient than solid brick construction, solid brick construction provides a higher level of structural stability and a classic, traditional look.

Ultimately, the choice between these two methods of construction will depend on the specific needs and priorities of the project,

Brick Is Expensive Due To High Labor Costs

Brick is a popular building material known for its durability, aesthetic appeal, and longevity.

However, it is also known to be more expensive than other building materials such as wood or concrete.

While the cost of brick can vary depending on a number of factors, one of the main reasons for its higher cost is due to the high labor costs associated with bricklaying.

In this article, we will explore the reasons why brick is expensive and how labor costs play a role in this.

Brick Manufacturing Process

The manufacturing process for brick involves a number of steps that contribute to its higher cost.

The raw materials for brick, such as clay, sand, and water, must be mined or extracted from the ground, which can be costly in terms of labor and equipment.

Once the raw materials have been collected, they are mixed together in a specific ratio to create a clay mixture that is suitable for brickmaking.

The clay mixture is then molded into bricks using a machine or by hand, which requires skilled labor.

After the bricks have been molded, they are left to dry for a specific period of time to remove any excess moisture.

This can be a time-consuming process that requires careful monitoring to ensure the bricks are dried evenly and do not crack or warp.

Once the bricks have been dried, they are fired in a kiln at high temperatures to harden them and give them their final shape and strength.

This process also requires specialized equipment and skilled labor, which can contribute to the higher cost of brick.

Labor Costs

One of the main reasons why brick is expensive is due to the high labor costs associated with bricklaying.

Bricklaying requires a high level of skill and expertise, as well as specialized tools and equipment.

Bricklayers must be able to accurately measure and cut bricks to fit a specific pattern or design, which requires a great deal of precision and attention to detail.

They must also be able to mix and apply mortar, lay bricks in a straight and level manner, and work efficiently to ensure the project is completed on time.

Due to the level of skill and expertise required, bricklaying is a specialized trade that often commands higher wages than other types of construction work.

This can contribute to the higher cost of brick construction. In addition to the labor costs associated with bricklaying, there are also other factors that can increase the cost of brick construction.

These can include the cost of transporting and storing bricks, the cost of purchasing and maintaining specialized tools and equipment, and the cost of obtaining permits and complying with building codes and regulations.

Benefits of Brick Construction

While brick construction may be more expensive than other building materials, it also offers a range of benefits that can make it a worthwhile investment. These benefits include:

- Durability: Brick is known for its strength and durability, and can last for decades or even centuries with proper maintenance.

- Aesthetic Appeal: Brick offers a classic and timeless look that can enhance the aesthetic appeal of a building.

- Energy Efficiency: Brick is a good insulator and can help to keep a building cool in the summer and warm in the winter, which can reduce heating and cooling costs.

- Fire Resistance: Brick is non-combustible and can help to prevent the spread of fire in a building.

- Soundproofing: Brick has good soundproofing properties and can help to reduce noise transmission between rooms or buildings.

While brick is known to be more expensive than other building materials, such as wood or concrete, this is largely due to the high labor costs associated with bricklaying.

Brick manufacturing requires specialized equipment and skilled labor, and bricklaying is a specialized trade that often commands higher wages than other types of construction work.

Despite its higher cost, brick construction offers a range of benefits, including durability, aesthetic appeal, energy efficiency, fire resistance.

Useful Articale For You

- Difference Between Concrete and Cement

- Size Difference Between Full and Queen

- Difference Between Vinyl and Laminate Flooring

- Difference Between Rock and Stone

- Difference Between Architect and Engineer

- Difference Between True North and Magnetic North

- Explain the Difference Between the Shell and the Skeleton in Architecture.

- Difference Between Patio and Porch

- Difference Between Marble and Granite

- Difference Between Concrete Spalling and Scaling

- Difference Between Primer and Paint

- Difference Between Drawing and Sketching

- Difference Between Stainless Steel and Steel

- Difference Between Steps and Stairs

- Difference Between Vaulted and Cathedral Ceiling

- Difference Between Beam and Girder

- What Is the Difference Between Malleability and Ductility

- Difference Between Stucco and Eifs

- What Is the Difference Between Intensity and Magnitude

- What’s the Difference Between a Basement and a Cellar

- Difference Between Dirt and Sand

- Difference Between Architecture and Architectural Engineering

- What Is the Difference Between Earthquake Magnitude and Intensity

- Difference Between Laminar and Turbulent Flow

- What Is the Difference Between Ductility and Malleability

What is Thin Brick Veneer?

Thin brick veneer, also known as brick tile or brick facing, is a type of brick product that is used to create a decorative or functional surface on walls, floors, or other interior or exterior surfaces.

Unlike traditional solid brick construction or brick veneer, thin brick veneer is a much thinner and lighter product, typically measuring between 0.5 to 1 inch thick, and can be adhered to a variety of surfaces without the need for additional structural support.

Thin brick veneer is made from real clay or fired clay and is created by cutting thin slices or “tiles” from larger bricks.

These slices are then processed to create a uniform thickness and shape and are often treated with special coatings or finishes to enhance their appearance and durability.

Thin brick veneer comes in a wide range of colors, textures, and finishes, and can be customized to match any design or aesthetic.

It can be used to create a variety of patterns, including running bond, herringbone, basket weave, and more, and can be installed on both interior and exterior surfaces, including walls, floors, fireplaces, and even outdoor kitchens and patios.

Installation of thin brick veneer is typically done using a thin-set mortar or adhesive and can be done by both professionals and DIY enthusiasts.

The ease of installation and lightweight nature of thin brick veneer makes it a popular choice for renovations or remodels, as it can be applied over existing surfaces without the need for additional structural support.

Overall, thin brick veneer offers many of the benefits of traditional brick construction, including durability, resistance to fire and pests, and a timeless aesthetic, while also being more versatile and easier to install.

It is a popular choice for both commercial and residential applications and can be used to create a wide range of design styles, from rustic and industrial to modern and sleek.

Real Bricks Don’t Fade

While it’s true that traditional clay bricks are known for their durability and resistance to fading, they are not completely immune to the effects of the environment and the passage of time.

In fact, over the course of many years, even the strongest and most well-made bricks can begin to show signs of wear and tear, including fading, cracking, and discoloration.

One of the primary causes of brick fading is exposure to sunlight and UV radiation. Over time, these rays can break down the pigments in the brick’s surface, causing it to lose its color and become dull or gray.

This is particularly true for bricks that are installed in areas with a lot of direct sunlight, such as south-facing walls or roofs.

In addition to UV damage, bricks can also fade due to exposure to the elements, including rain, wind, and snow. Moisture can seep into the surface of the brick, causing it to become discolored or stained over time.

This is particularly true for bricks that are installed in areas with high levels of pollution or industrial activity, as these can contribute to the buildup of grime and dirt on the surface of the brick.

While it’s true that high-quality bricks are designed to last for many years, even they can begin to fade over time.

In order to prevent this from happening, it’s important to take steps to protect your brick surfaces from the elements and UV radiation.

This can include using a sealer or protective coating to shield the brick from moisture and sunlight, as well as regularly cleaning the surface of the brick to remove any buildup of dirt or grime.

With proper care and maintenance, it is possible to keep your brick surfaces looking beautiful and vibrant for many years to come.

Man-Made Thin Brick Veneer

Man-made thin brick veneer is a type of brick product that is created using synthetic materials, rather than natural clay or fired clay.

Unlike traditional thin brick veneer, which is made from real brick slices, man-made thin brick veneer is created using a variety of materials, including cement, polymers, and other synthetic materials.

One of the primary advantages of man-made thin brick veneer is its versatility and ease of installation.

Because it is created using synthetic materials, man-made thin brick veneer can be manufactured in a wide range of colors, textures, and finishes, and can be customized to match any design or aesthetic.

It can be installed on a variety of surfaces, including drywall, wood, and concrete, and can be cut to size and shape using standard cutting tools.

In addition to its ease of installation, man-made thin brick veneer also offers many of the same benefits as traditional brick construction, including durability, resistance to fire and pests, and a timeless aesthetic.

It is a popular choice for both commercial and residential applications and can be used to create a variety of design styles, from classic and traditional to modern and contemporary.

However, it’s important to note that man-made thin brick veneer may not have the same level of durability or longevity as traditional brick construction.

Because it is created using synthetic materials, it may be more susceptible to damage from the elements and wear and tear over time.

Additionally, a man-made thin brick veneer may not have the same natural variations in color and texture as real brick, which can impact the overall aesthetic and authenticity of the installation.

Overall, a man-made thin brick veneer can be a great choice for those looking to achieve the look and feel of traditional brick construction without the high cost or labor requirements.

However, it’s important to carefully consider the materials and installation process to ensure that the final result meets your aesthetic and functional needs.

So Which Is Better? Solid Brick vs Brick Veneer?

When it comes to choosing between solid brick and brick veneer for your construction project, there is no clear “better” option.

Both have their own unique advantages and disadvantages, and the right choice will depend on a number of factors, including budget, design preferences, and the specific needs of your project.

Solid brick is a traditional construction material that has been used for centuries, and it offers a number of advantages for those looking for a classic, durable, and long-lasting building material.

Some of the key benefits of solid brick construction include:

- Durability and strength: Solid brick is known for its strength and durability, and can withstand a wide range of environmental conditions, including wind, rain, and extreme temperatures. It is also resistant to pests, fire, and other hazards, making it a reliable choice for long-term construction.

- Energy efficiency: Solid brick has a high thermal mass, which means it is able to absorb and store heat from the sun during the day and release it slowly at night. This can help to regulate indoor temperatures, reducing the need for heating and cooling systems, and ultimately lowering energy costs.

- Acoustic insulation: Solid brick is an excellent sound barrier, and can help to reduce noise pollution from both inside and outside the building. This can be particularly beneficial in urban areas or in buildings that require a quiet environment, such as hospitals or schools.

- Aesthetic appeal: Solid brick has a timeless, classic look that many people find appealing, and it can be used to create a variety of architectural styles, from traditional to modern.

While solid brick has many advantages, it also has some drawbacks that should be considered before making a final decision. These include:

- Cost: Solid brick is a more expensive construction material than other options, such as brick veneer or wood framing. This is largely due to the high cost of materials and the labor-intensive installation process.

- Weight: Solid brick is heavy, and requires a strong foundation and support structure to ensure it remains stable and secure over time. This can add to the overall cost and complexity of the construction process.

- Limited design flexibility: Because solid brick is a relatively inflexible construction material, it may not be suitable for all design styles or building types. It can also be difficult to modify or renovate solid brick structures once they are built, which can limit their long-term flexibility.

Brick veneer, on the other hand, is a more lightweight and flexible option that offers its own set of advantages for construction projects. Some of the key benefits of brick veneer construction include:

- Cost: Brick veneer is generally less expensive than solid brick since it requires less material and labor to install. This can make it a more cost-effective option for those on a tight budget.

- Lightweight: Brick veneer is much lighter than solid brick, which means it does not require as strong of a foundation or support structure. This can simplify the construction process and reduce overall costs.

- Design flexibility: Brick veneer can be manufactured in a wide range of colors, textures, and finishes, making it a versatile option for a variety of design styles and aesthetic preferences. It can also be easily modified or renovated, allowing for greater long-term flexibility.

- Easy to install: Brick veneer is typically installed using a simple masonry system, which can reduce the time and labor required for construction. This can also help to speed up the overall construction timeline, which can be beneficial for those with tight schedules.

While brick veneer has many advantages, it also has some potential drawbacks that should be considered. These include:

- Less durability: Brick veneer is generally less durable and long-lasting than solid brick, and may be more susceptible to damage from environmental factors like wind, rain, and temperature fluctuations. It may also require more maintenance over time to ensure it remains in good condition.

Solid Brick Vs Brick Veneer

The biggest difference between brick veneer and solid brick is the main building support. Solid masonry is the structural support of the building. With brick veneer, the structural support comes from the concrete, steel, or wood that makes up the backup wall, and the brick is on the exterior for aesthetic purposes.

When Did They Stop Building Solid Brick Houses?

The shift away from structural brick began after World War II. Mid-century consumers wanted suburban homes that looked distinct from their urban counterparts and newer building codes no longer required brick. That, meant less demand for both the material and the masons needed to install it.

What Is Brick Veneer Made of?

Brick veneer is a method of construction where a property of either a wooden or steel frame is concealed with a single layer of bricks as the exterior layer. It offers the same look as double brick, however if the bricks were to be removed the structure of the house would still stand.

Is Brick Veneer Good?

Compared to solid brick, brick veneer is a much better insulator. When brick veneer is installed, there will need to be space between it and the exterior walls and then insulation can be added. Flexible, Easy Installation: Brick veneer can be installed at any point after the building is complete.

What Is Solid Brick?

Solid masonry, also known as solid brick or double brick construction, consists of two layers of brick walls, or an inner wall of cinder or concrete blocks and an outer layer of brick. This double-wall is the skeleton and support of the structure. Each layer of block or brick construction is known as a wythe.

Is Brick Veneer Real Brick?

Brick veneer is not, contrary to popular belief, composed of thin pieces of brick, such as is found in veneer floors, patios, and decorative interior elements. Brick veneer houses look almost identical to solid brick structures, except that they are built using a very different technique.

Disadvantages of Brick Veneer

The cons of building with a veneer are: Single-layer design: The one layer of brick means it is not as strong or durable as a solid brick wall. Water damage: When not installed correctly, a veneer wall can potentially cause water issues.

When Were Red Bricks Invented?

China. In Asia, bricks can be dated back to 4400 BC. Located in the area of Chengtoushan, China, the bricks were found to be made of red clay and baked at over 1100 degrees Fahrenheit. The bricks were used as indoor flooring, and are one of the earliest examples of fired bricks.

When Were Modern Bricks Invented?

Fired bricks as we know them today, made from molds and baked in kilns, probably came to the United States around the 1600s with English colonists. We know that brick buildings in the United States went up around 1611, but the building boom of the 19th century made brick the dominant building material it is today.

Who Invented Bricks?

The earliest discovery of man-made bricks dates back to 7000 BC. Found in Turkey, the bricks were made of mud and were dried naturally by the sun. Ancient Egyptians were also known to make sun-dried bricks out of clay and straw.

How Bricks Were Made in the Past?

In medieval times, bricks were made by workers kneading the clay and then placing it in wooden moulds. Excess clay was wiped off and the brick shaped clay was removed from the frame. This was all done by hand and indeed bricks were still handmade until about 1885.

Who Invented Bricks and Mortar?

It was invented in 1794 by Joseph Aspdin and patented on 18 December 1824, largely as a result of efforts to develop stronger mortars. It was made popular during the late nineteenth century, and had by 1930 became more popular than lime mortar as construction material.

How Were Bricks Made in the 1800s?

Bricks were traditionally formed by hand by packing clay into wooden molds. By the 1870, brick-making machines had become more common. The machine used by the Schroeder Brickyard at its opening used steam to pack brick molds with tempered clay.

Uses of Bricks

- Construction of walls of any size.

- Construction of floors.

- Construction of arches and cornices.

- Construction of brick retaining wall.

- Making Khoa (Broken bricks of required size) to use as an aggregate in concrete.

- Manufacture of surki (powdered bricks) to be used in lime plaster and lime concrete.

Characteristics of Bricks

- Size. The size of the brick should be uniform and must be of standard size.

- Shape. The brick must be of rectangular shape.

- Color. Good brick must possess uniform color which may be either deep red or cherry.

- Texture. The surface of the brick must not be too smooth.

- Compactness.

- Compressive strength.

- Hardness.

- Soundness.

Advantages of Bricks

- Bricks are low-maintenance. Bricks don’t need painting, sealing or protection from termites.

- Bricks offer thermal properties. Brick is a building material that has exceptional “thermal mass” properties.

- Bricks are made from natural products.

- Protection from fire, wind and moisture.

- Bricks are beautiful.

Thermal Properties of Bricks

Bricks possess a low thermal conductivity which averages between 0.5 – 1.0 W/(m/K). The thermal conductivity of a material directly relates to its ability to effectively transfer heat through it.

How Long Does Brick Veneer Last?

If properly installed, a brick veneer house can last for decades. Brick veneer is not only a beautiful finish, but it’s virtually maintenance-free, extremely durable and has even been shown to increase a home’s value. The siding itself and a brick veneer house can last for up to 50 years on average.

Masonry Veneer Area

Masonry veneer walls consist of a single non-structural external layer of masonry, typically made of brick, stone or manufactured stone. Masonry veneer can have an air space behind it and is technically called “anchored veneer”. A masonry veneer attached directly to the backing is called “adhered veneer”.

Types of Masonry Veneer

There are basically two types of veneer—anchored veneer and adhered veneer.

Masonry Veneer Vs Frame Construction

Frame homes have wooden studs running vertically through the walls with space for insulation in between them. Masonry homes won’t have wooden studs. They’d have blocks of concrete, tile, or stone between the exterior material of the wall and the drywall.

Is Stucco Masonry Veneer?

Stucco is primarily a masonry concrete product and is a form of covering for the structural, load bearing construction of the dwelling. Stucco is not a construction type, it is material that is over wood frame or masonry.

Like this post? Share it with your friends!

Suggested Read –

Leave a Reply