What is Salt Concrete Finish?

Important Point

As one of the older, more conventional decorative concrete finishes, salt finish concrete has become the most popular in unfreezing / thaw regions around the country.

For a little additional cost, you can add texture to just about any hardscape. With the popularity of decorative concrete along with the wide range of decorative finishes available today, the salt finish is not used much currently.

However, Lance Boyer, owner of Trademark Concrete Systems, Oxnard, Calif., says that they occasionally see the finish specified on plans, adding that it is sometimes specified in areas between characteristic panels using more expensive decorative finishes.

The salt finish is more decorative than broom finished concrete, which is often the alternative consideration.

Landscape architects who need concrete to look like concrete tend to specify salt finishes for that reason.

Also, read: What Is Development length | What Is Development Length of Bars

Rock Salt Concrete Finish Installation Procedure

Installing rock salt finish concrete requires little extra material or equipment – rock salt, and a roller to press it on the surface of fresh concrete is it.

Sometimes an installation also involves colored concrete with either integral or dry-shake color hardeners. As with most decorative finishes, the timing for the installation is critical.

There’s little difference about finishing and placing concrete in preparation for a salt finish. During the bull-floating operation, care ought to be taken to remove the lines created by the float.

Finishers often finish a slab either with Fresnos or using hand trowels to get a smooth finish to record the print of the salt better. Make sure to finish just after the water sheen has disappeared from the surface.

For the best results, workers should broadcast salt once the concrete is just beginning its initial setting phase. The stiffness of the concrete needs to be the same as it would be for stamping textures or patterns.

If you push your finger with moderate pressure to the surface, it must penetrate approximately 1/4 inch at most.

Some finishers also gauge timing by lightly pressing the surface to see if concrete paste or colour sticks for their finger–proceeding when there’s no residue in their finger. Rock salt rated as”coarse” or”extra coarse” would be the most popular sizes to use.

Because it’s broadcasted by hand in a similar way to throwing dry-shake colour hardeners, skill is required by the worker to achieve an even distribution.

Having good access around the work area also is important, so broadcasting is limited to 15 or 20 lineal feet.

Also, read: IS 516:1959 Most Important Point (Method of Tests For Strength of Concrete)

Useful Article for You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is a Frame Structure

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is Mdf Mean

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Overhang

- What Is Sand Blasting

- What Is a Span Bridge

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- What Is Pedestal

- What Is Plumbing Fixtures

- What Is Slab Construction

- What Is Calacatta Quartz

- What Is Auxiliary View

- Sheepsfoot Roller

- Live Load Vs Dead Load

- What Is 1 Flight of Stairs

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- What Is a Moment Frame

- Arch Foundation

- What Is a Stair Landing

- What Is Stone Masonry

- What Is a Spandrel Beam

- What Is Pier and Beam Foundation

- What Is Levelling

- What Is a Pile Cap

- What Is a Mat Foundation

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is Modulus of Rupture

- What Is a Flush Door

- What Is Residential Construction

- What Is a Concept Sketch

- What Is the Best Foundation for a House

- What Is Oblique Drawing

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is a Monolithic Slab Foundation

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is a Caisson in Construction

- What Is a Tremie

- What Is Tributary Area

- What Is Shoring Construction

- What Is a Cason

- What Is Wall Putty

- What Is the Difference Between Mortar and Concrete

- What Is Bhk

- What Is Sbc of Soil

- What Is Plinth Level

- What Is Water Proofing

- What Is Mix Design of Concrete

- What Is Fine Aggregate

- What Is Retention Money

- What Is Design Mix

- What Is Isometric Scale

- What Is Retrofitting a Building

- What Is a Good Angle for Stairs

- What Is Gypsum Board

- What Are Forms in Construction

- Cement Consumption in Plaster

- Types of Interior Walls

- Roof Covering Types

How to Create a Salt Finish?

As its name implies, a salt finish is traditionally achieved with the same coarse rock salt sold to be used in water softeners or as a deicer in winter.

Concrete finishers broadcast the salt particles over moist concrete and then press the grains to the surface using a roller or float.

After the concrete sets (Final Setting Time of Concrete), they power wash away the salt, revealing a speckled pattern of shallow indentations left by the dislodged salt particles.

While salt is relatively quick and easy to master, there are newer methods that may speed up the procedure for doing away with the salt altogether.

Salt finishes are more commonplace in the warmer southern and western regions of the country. The reason in areas subject to freezing weather, water will accumulate from the indentations and freeze, potentially causing spalling.

But if you like the look and use of good-quality concrete protected by a waterproofing sealer, a salt finish ought to be durable enough to endure any climate.

Also, read: What Is Construction Contract | Types of Engineering Contracts | Percentage-Rate Contract

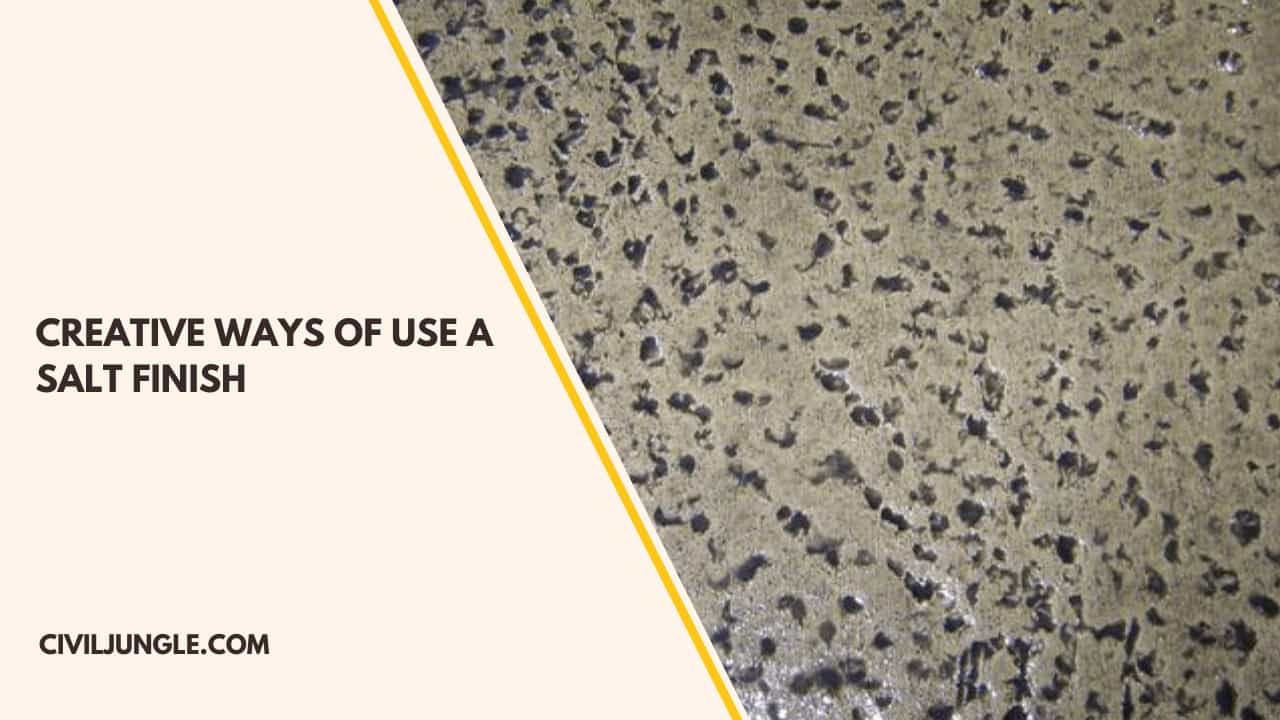

Creative Ways of Use a Salt Finish.

Salt finishes are attractive alone but are particularly stunning when used in combination with coloured concrete and other decorative finishes.

Some contractors who specialize in stamped concrete usage salt finish as an interesting contrast to brick and stone patterns.

Landscapers have long relied on salt finishes to create rustic garden pathways with the look of natural stone. And the finish is still quite popular with pool contractors, owing to its inherent nonskid texture.

Other Creative Ways to Use a Salt finish Concrete:

- As a decorative Edge for swirl-troweled or broom-textured concrete

- In large panels bordered by bands of smooth concrete

- To add texture to Coloured concrete overlays

- In square or diamond-shaped panel arrangements separated by scored or saw-cut joints

Salt Finish Concrete

A salt finish is a simple and inexpensive way to dress up what would otherwise be plain concrete flatwork. It’s achieved by pressing coarse rock salt into the surface of fresh concrete, allowing the concrete to set, and then washing the salt away with a stream of water.

Salt on Concrete

The answer is yes, salt does indirectly damage your concrete driveways, patios and sidewalks. Bumps and potholes don’t just appear due to regular wear and tear – salt damages concrete over time by causing corrosion to occur under the surface, leading to discolored, cracked and crumbling concrete.

Salt Concrete

Salt damage to concrete mainly occurs due to chemicals that react with the surface of the road or pavement. In lower temperatures, this extra water adds additional ice to the concrete upon refreezing, which adds hydraulic pressure to the concrete. However, good quality concrete is more resistant to salt damage.

Like this post? Share it with your friends!

Suggested Read –

- What Is a Highway Flyover

- What Is Rolling Margin | The Procedure of Rolling Margin

- Difference Between CPM and PERT | What Is CPM & PERT

- Difference Between One Way Slab and Two Way Slab | What is Slab

- 23 Different Types Cements Available in India and As Per IS Standards

- Carbon Steel vs. Stainless Steel | What Is Carbon Steel | What Is Stainless Steel

- What Is Plaster | Plaster Ratio | History of Plastering | Requirements of Good Plaster

Leave a Reply