Introduction of Pile Cap:

Important Point

- The pile cap is a type of thick concrete mat-like structure which rests on the pile (timber or concrete) which gives a stable foundation to the whole system.

- This concrete pile cap transfers the entire load of the superstructure to the into the piles, which gives you a stable bearing capacity.

- The similar structure of the pile cap is a raft foundation, where there is also a concrete block-like structure is constructed.

Pile Cap Design:

The pile cap is a mat-like structure which rests on the group of piles to transfer loads from the super structure.

By IS 2911-2010, the pile cap could be arranged that the column’s load is spread at 45° out of the top of the cap.

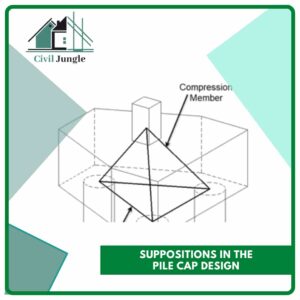

1. Suppositions in the Pile Cap Design

- The pile cap is must be rigidly set to the structure.

- Though piles are slight elastic column, that’s why some distortions will be found, and we need to measure those in the plan.

- The heads of the pile are pivoted to the pile cap to provide safety from the bending moment occur in a pile.

2. Limitations of Pile Cap Designing

- Shape and form of the pile cap.

- Quantity of steel is used in the pile cap.

- Reinforcement placing in the pile cap.

- Depth of pile.

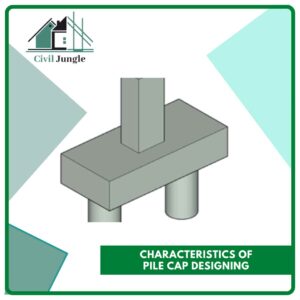

3. Characteristics of Pile Cap Designing

- The dimension of the pile is considered by the overhanging portion of the pile cap is not less than 100 mm, it would be highly preferable if you provide 150 mm.

- The thickness of the pile cap is needed to be higher because the reinforcements of columns may come out and overlay to the reinforcement of the pile cap.

- In pile cap construction, the clear cover must be more than 40 mm.

- The pile cap’s span to thickness ratio must be not excess than 5. The pile cap must be relatively rigid to transfer the load to the pile section to downwards.

- The thickness must not be below 500 mm, and it’s decreased to the 300 mm on the peripheries.

- The pile must not less than 50 mm into the pile cap.

- The upper coarse of pile cap is not less than 75 mm thick concrete.

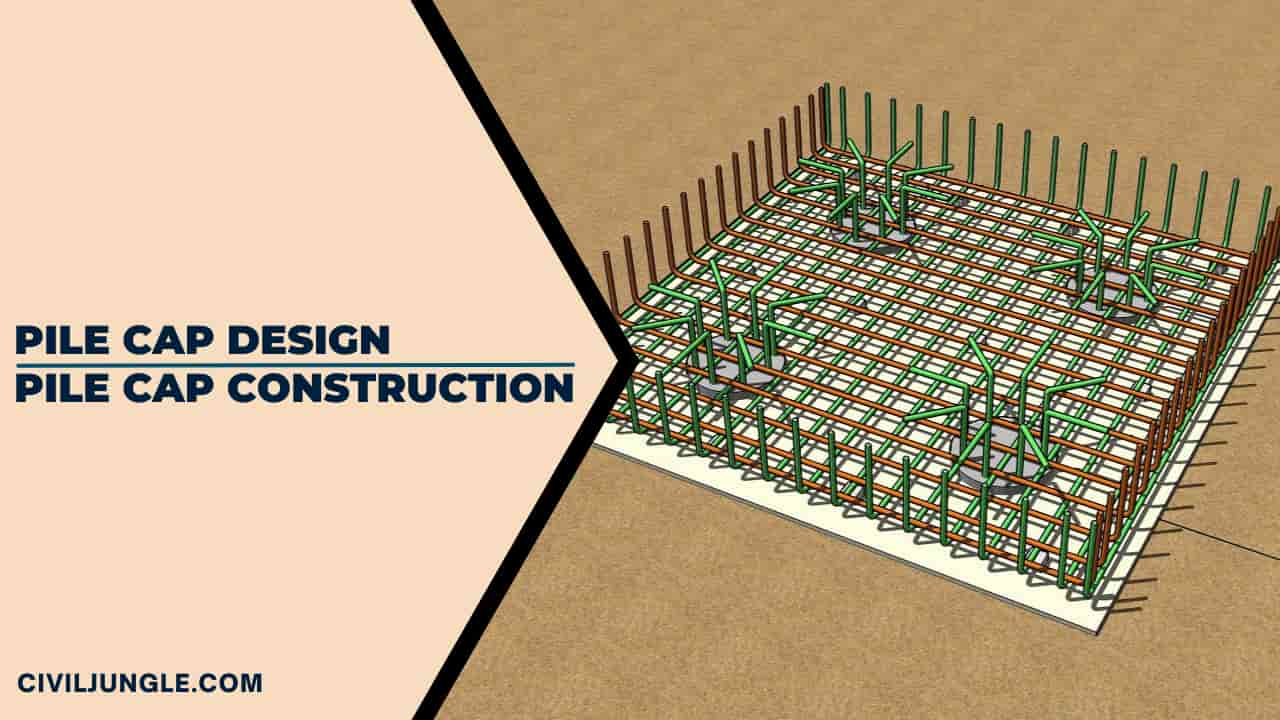

Pile Cap Construction:

- The pile cap is a mat-like structure which is made of cement, sand and small aggregates.

- This mixture is placed in the required place, and it is supported by the framework to resist the whole structure from sagging and crack, this entire process is termed as shuttering and reinforcing.

- In a pile, cap reinforcements are placed in the longitudinal section of the pile cap, and it creates a wire type of reinforcement.

- At first, the reinforcement cage is placed in the pointed place; then the framework is done by timber to hold the wet concrete.

- After the concrete has placed then the most vital job is to remove the air bubbles from the concrete; otherwise, the concrete gets porous, and it may be weaker.

- After concrete placing, compaction and finishing happen then the concrete starts its internal reaction and it generates a lot of amount of heat that’s why we need to cure the concrete by the water curing process.

- In the vast amount of concrete placing, there is a coolant that is used to reduce the heat, which is produced by hydration is called refrigerant coolant.

- So, these are those actions which are very useful during the construction of the pile cap.

Piles Structure:

The pile is generally a strong cylinder structure which supports loads of superstructure and transfers it to the subsoil. The pile cap is constructed just above the pile.

Pile foundation is used in some following situations, those are-

- Pile foundation is used when the subsoil is weaker, but the superstructure load is too heavy to carry that by shallow footing, then we use a pile foundation structure.

- When the structure load is too heavy like a bridge, water tank, high rise building, etc., we need to use a pile foundation.

Piles are mainly two types, those are-

- End-bearing Pile: In this type of pile, the end portion of this pile rests on the hard starts below the ground. In this type of pile is acting as a vertical column.

- Friction Pile: when the structural load is too heavy, but the subsoil is not too hard, and we can not find hard strata in a reasonable depth, then we need to use friction pile. This type of pile dia is too large because to increase the surface area for the friction.

Pile Cap Foundations:

Foundation of the pile cap depends upon various points, those are-

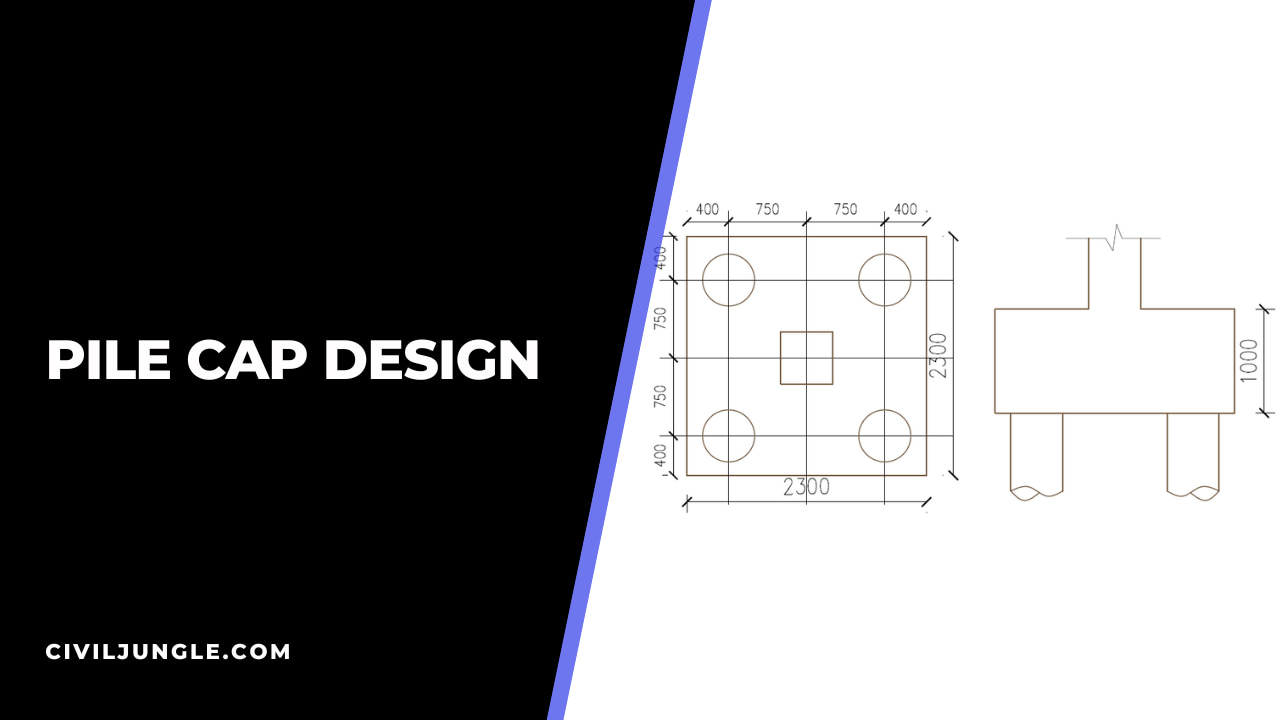

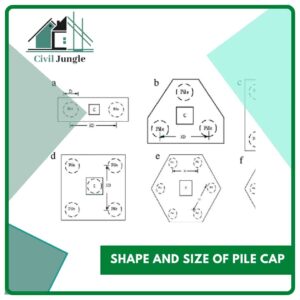

1. Shape and Size of Pile cap

The shape and dimensions depend upon the numbers of the pile and the spacing between two piles.

Like- Triangular pile cap for three piles, hexagonal pile cap for 6-7 piles, rectangular pile cap for other numbers of the pile, etc.

This type of pile cap is used to reduce the pile cap area because it’s compact the position of the pile.

The pile cap should not be overhanging more than 150 mm. This minimum area provides sufficient length to:

- Tension reinforcement has a large radius bend.

- Make sure that enough reinforcement cover.

- Must satisfy construction tolerance.

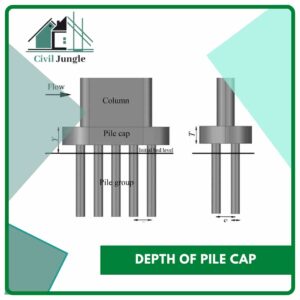

2. Depth of Pile Cap

Depth of pile cap is another section in the pile cap foundation works. The following criteria are considered-

- Shrinkage of clay

- Shear capacity of the pile cap

- Pile anchorage

- Natural condition like frost attack

- The water table of the ground surface

Naturally, the depth of the pile cap is much more than pad footing; that’s why it can carry more concentrated loads.

Pile cap depth for different diameters of the pile-

| Pile Diameter (mm) |

Depth of Pile (mm) |

| 300 | 700 |

| 350 | 800 |

| 400 | 900 |

| 450 | 1000 |

| 500 | 1100 |

| 550 | 1200 |

| 600 | 1400 |

| 750 | 1800 |

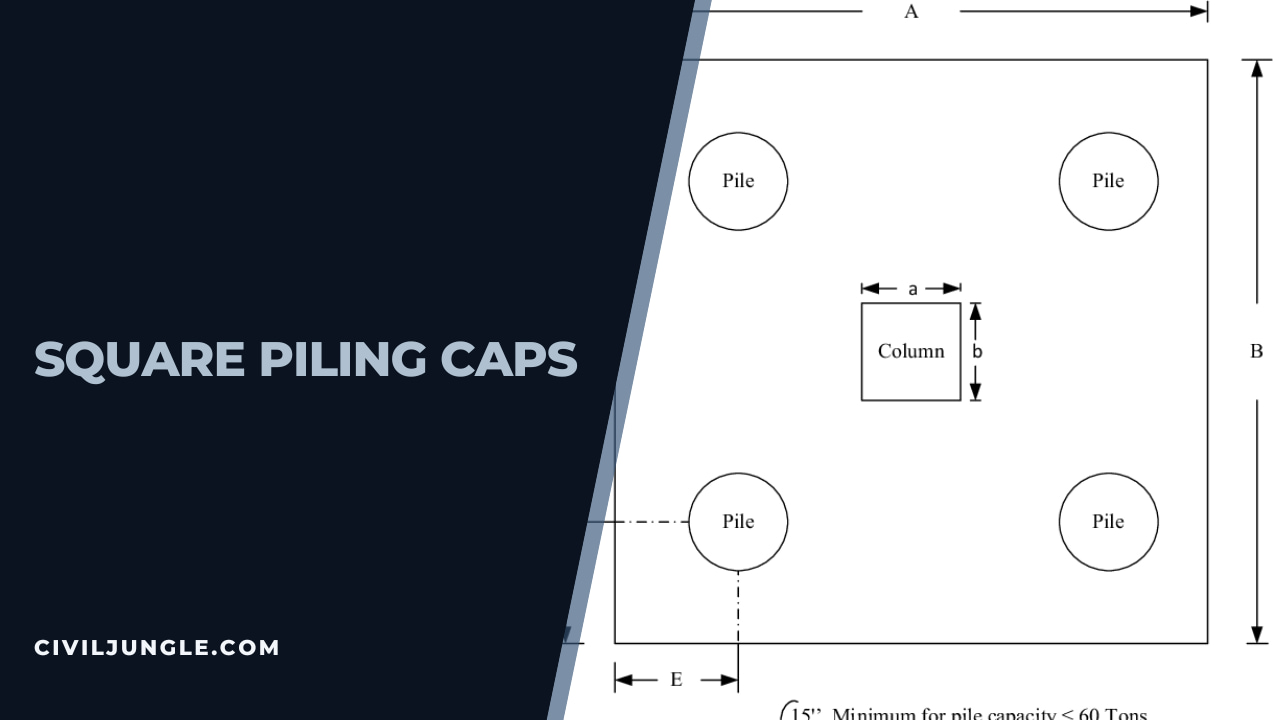

Square Piling Caps

- The square pile cap is one type of popular pile cap structure.

- In this pile cap structure, all the piles are situated in a combined and compacted way.

- The square pile cap is provided when the number of piles is even; it may be four, six, eight etc.

- The square pile cap is highly used in bridge structure, high rise building, etc.

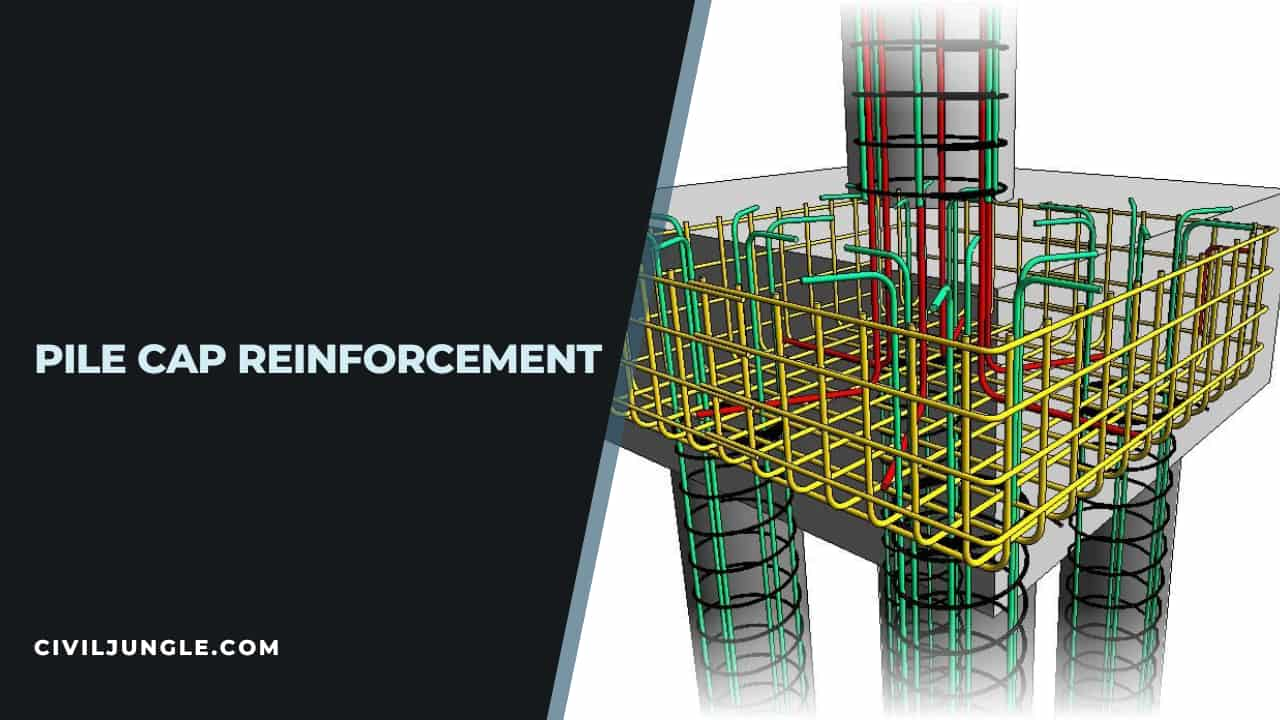

Pile Cap Reinforcement

- Pile cap reinforcement and it’s calculation is one of the most essential things in the pile cap section.

- Before starting the main calculation, we need to find out the main volume of the pile cap that is (length x breadth x height)

- Bar bending schedule table for reinforcement:

|

Spec |

Dia of Rod (mm) | No. of Rods | Length of Rods. (M) |

Total Length |

| Vertical bar |

12 |

12 |

21.3 |

255.6 |

| Inner spacer ring |

16 |

11 |

1.59 |

17.49 |

| Outer spiral ring |

8 |

101 |

1.65 |

166.65 |

- In pile cap designing, we use reinforcement cage; it increases the strength of vertical concrete column when the soil condition is not good.

- In the case of the prefabricated pile, the piles are directly placed in the site, and then the pile cap reinforcement works are done.

Also, Read: What Is Soil Vent Pipe | How Does Soil Stack Pipe Works | Soil Vent Pipe Material | Types of Plumbing System

Pile Cap Design

The structural design of a pile cap is similar to the design of spread footing. The load acting on the pile cap from the superstructure and piles are resisted by the developments of bending moment and shear force in the pile cap.

Piles Structure

A pile foundation is defined as a series of columns constructed or inserted into the ground to transmit loads to a lower level of subsoil.

A pile is a long cylinder made up of strong material, such as concrete. Piles are pushed into the ground to act as steady support for structures built on top of them.

Also, Read: Difference Between Tied Column and Spiral Column | What Is Spiral Column | What Is Tied Column

Pile Cap Design Example

consider 150mm offset from the pile and space between piles as 2.5 times pile diameter.

Effective depth, d = 1000-50-20/2 = 940 mm > 750mm; (2.5×600/2) Ok.

The critical section of the pile shall be considered as 20% of the diameter of the pile inside of the face of the pile.

Concrete Piles

What is a concrete pile? A concrete pile is a foundation driven deep into the ground to support the structure, unlike shallow or wide foundations such as Isolated Footings or Combined Footings. They are usually much thinner in diameter or width than in length.

Pile Cap Foundations

What is a Pile Cap? Basically, a pile cap is a thick concrete mat. This mat can be found on concrete or timber piles and those piles are driven into the unstable ground, or soft ground, to create a stable foundation. The concrete pile cap will then distribute the entire load of the building.

Pile Cap Formwork

Pile caps are constructed by excavating an area around the group of piles to enable formwork to be inserted. The pile tops may be trimmed to ensure they are at the same height. A reinforcement cage is then built and positioned in the formwork cast box and fastened to the piles.

Pile Cap Reinforcement

The reinforcement of a pile cap is designed to resist the bending moments and shear forces that are induced by the load from the columns or walls. The reinforcement layout and spacing are determined by the structural engineer based on the loads and soil conditions. Typically, the steel bars are placed in two perpendicular directions to provide both longitudinal and transverse reinforcement.

Pile Caps

The concrete cover over the reinforcement bars in a pile cap is also an important consideration. The cover is the thickness of concrete between the surface of the reinforcement bars and the surface of the concrete. It is important to maintain an adequate cover to prevent corrosion of the steel bars and ensure the durability of the structure. The required cover thickness is specified in the design and should be checked during construction to ensure compliance.

Pilecap

A pile cap is a type of foundation that is used to support columns or multiple piles. It is a thick concrete mat that is placed on top of the piles, spreading the load from the columns or walls over a larger area. The pile cap is designed to transfer the load from the columns or walls to the piles, which are driven deep into the ground to provide support for the structure.

What Is Pile Cap?

Pile caps are typically used in situations where the soil conditions are not strong enough to support the weight of the structure directly or where the loads are too heavy for individual piles to bear. They are commonly used in bridges, high-rise buildings, and other structures that require a deep foundation system.

Pile and Pile Cap

Piles and pile caps are both components of a deep foundation system used to support heavy structures, such as high-rise buildings, bridges, and industrial facilities. Piles are long, slender columns made of concrete, steel, or timber that are driven deep into the ground to provide support for a structure.

Concrete Pile Caps

A concrete pile cap is a type of foundation system used to transfer the load from a column or wall to a group of concrete piles. It is essentially a thick concrete mat that is placed on top of the piles and serves to distribute the load from the structure over a larger area. Concrete pile caps are commonly used in situations where the soil conditions are too weak to support the weight of the structure directly or where the loads are too heavy for individual piles to bear.

Pile Cap Details

Pile cap details vary depending on the specific project and the requirements of the design. However, there are several common features that are typically included in a pile cap design. Here are some details that may be included in a pile cap design:

- Reinforcement: Pile caps are typically reinforced with steel bars or mesh to provide additional strength and prevent cracking. The reinforcement is typically placed in both the top and bottom of the pile cap.

- Pile layout: The layout of the piles is an important factor in the design of a pile cap. The spacing, size, and number of piles are all taken into consideration when designing the pile cap.

- Size and shape: The size and shape of the pile cap are determined by the loads that it will be supporting. The pile cap is typically designed to be larger than the column or wall it supports, and it is often rectangular or square in shape.

Pile Cap Meaning

A pile cap is a structural component used in building foundations to transfer the load from a column, wall, or superstructure to a group of piles. It is essentially a thick concrete mat that sits on top of the piles and distributes the load from the structure over a larger area, reducing the stress on each individual pile.

Pile Cap Reinforcement Details

Here are some of the typical reinforcement details that may be included in a pile cap design:

- Main reinforcement: The main reinforcement bars are placed in the bottom of the pile cap and are designed to carry the majority of the load. The number, size, and spacing of the bars depend on the loads that the pile cap will be carrying and the soil conditions.

- Top reinforcement: Top reinforcement bars are also included in the pile cap to provide additional strength and prevent cracking. These bars are typically placed in a grid pattern and are designed to resist bending and shear forces.

- Stirrups: Stirrups are used to hold the main and top reinforcement bars in place and provide lateral support. They are typically placed at regular intervals along the length of the main reinforcement bars.

- Hooks and bends: Hooks and bends are used to connect the reinforcement bars and ensure that they are properly anchored to the concrete. These details are critical in preventing the reinforcement bars from slipping or pulling out of the concrete.

Types of Pile Cap

The shapes of pile caps are typically either:

- Triangular (for 3 piles).

- Hexagonal (for 6-7 piles).

- Rectangular (for all other number of piles).

Like this post? Share it with your friends!

Suggested Read –

- Foundation Structure

- Polysulfide Sealant Vs Polyurethane Sealant | Functions of Sealants | What Is Polysulphide Sealant | What Is Polyurethane Sealant

- What Are Survey Levelling | Important Terms Related to Levelling | What Are Different Types of Levelling | Types of Trigonometric levelling

- Parking In India | What Is Parking | Parking Statistics | Types of Car Parking | How to Park a Car Perpendicular | Types of Parking Spaces

- Building Layout | How to Building Layout | What Is Method of Layout of Building | Control Lines of Construction | Construction Layout

- What Is Road Pattern | Different Types of Road Patterns | Grid Pattern Definition | Radial Pattern | Rectangular or Block Pattern | Minimum Travel Pattern

- Definition of Shear Force and Bending Moment | What Is Shear Force | What Is Bending Moment | Relation Between Loading, Shear Force & Bending Moment

Originally posted 2023-04-15 17:38:22.

Leave a Reply