What Is Quarrying of Stones?

Important Point

You must have heard the word mine and quarry. The operations of taking out the materials from the ground at great depths are known as mining, whereas in the case of the quarry, the operations for taking out the match as (Stone) are carried out at ground level in an exposed condition.

The process of taking out stones from the natural rock is known as “quarrying” stones thus obtained are used for various engineering purposes.

Before discussing the methods of quarrying, let us discuss the natural bed and plane of cleavage, which ply an important role in quarrying operation.

Natural Bed

The building stones are obtained from rocks. These rocks have a distinct plane of division along which the stones can be easily split-up. This plane is known as a “natural bed of stone.”

In stone masonry, the general rule to be observed is the direction of the natural bed should be perpendicular to the direction of the pressure, such an arrangement of stones gives maximum strength of stonework.

Natural beds of stone can be detected by pouring water and observing its fall in the direction of layers. Which respect to natural beds, stones for different work are placed in different situations as follows.

In stone arches, the stones are placed with their natural beds in a radial manner.

Stone in case of cornices, string courses, etc.Should be placed in the vertical direction of natural beds.

Stones of building walls should be placed horizontally in the direction of their natural beds.

Plane of Cleavage

Some rocks possess planes of stratification or cleavage. The rocks can be easily split along these planes.

All sedimentary rocks have a distinct layer of stratification or cleavage. They are called stratified rocks.

Also, read: What Is Pier Foundation | Types of Drilled Piers | Advantages and Disadvantages of Drilled Pier Foundations

Considerations for Quarrying of Stones

After the site selection, some important considerations are to be followed before starting the quarrying of stones.

Which are as follows:

The rock surface should be properly checked for cracks and fissures. The presence of these may cause planes in the stones, along which they may split. Then, the quarrying will be easy and quick as well as economical.

- Layout should be prepared, which contains different stages involved in quarrying operation.

- The machines used should be tested to operate them easily and quickly.

- If the top surface of the site contains soft soil, then it should be removed and dumped.

- The removal of stones should be done carefully, otherwise, there may be chances of landslides or slips, which can cause severe damage to the lives of labor.

Methods of Quarrying

Following are the common methods of quarrying

- Digging.

- Heating.

- Wedging.

- Blasting.

#1. Digging-

In this method, stones arlr merely excavated with the help of suitable instruments. This method is useful when soft stones occur at low levels in the ground.

#2. Heating-

In this method, the top surface of the rock is heated. Due to unequal expansion, the upper layer of the rock separates out and is indicated by a dull bursting noise.

The detached blocks are then removed. This method is useful when the rock formation consists of horizontal layers at shallow depth.

#3. Wedging-

If the rock surface contains cracks of fissures, this method is adopted. Steel wedges or points are driven through such cracks by means of a hammer.

Blocks of stones are then shifted, and they are removed with the help of suitable instruments.

If natural cracks are not available, artificial cracks are formed. This method is adopted for rocks that are comparatively soft.

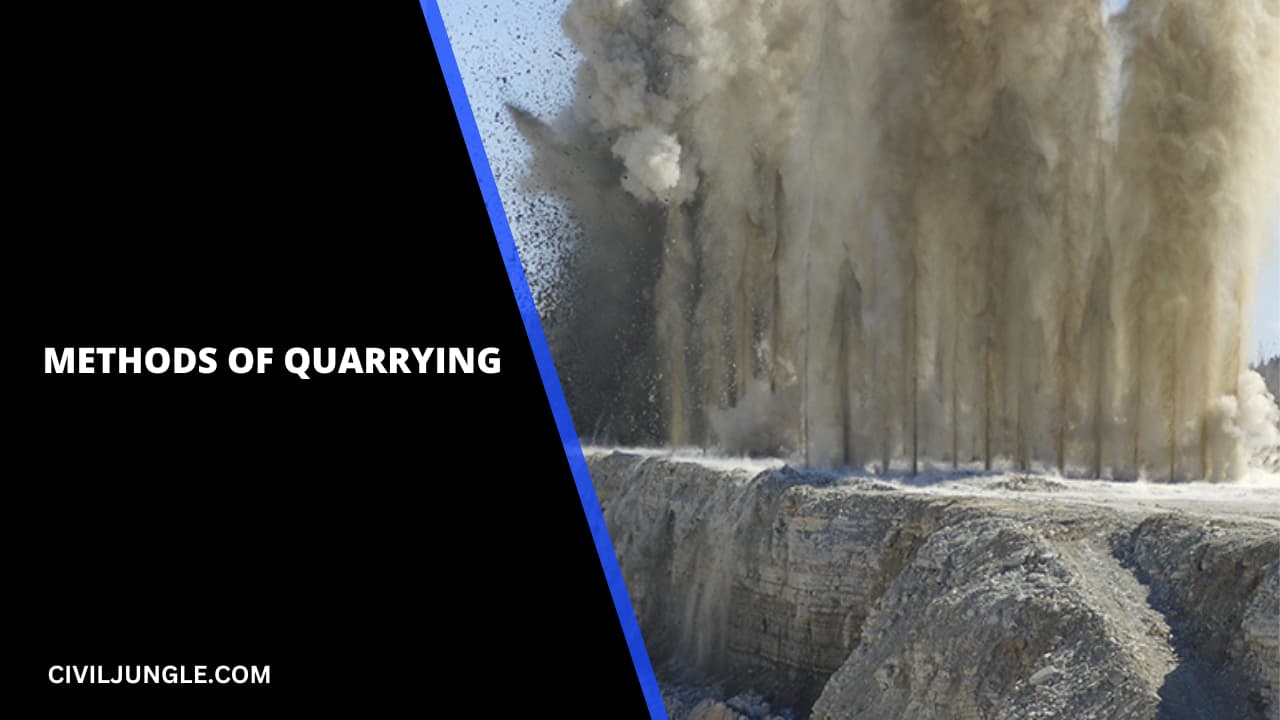

#4. Blasting-

Explosive is adopted in this method of quarrying to convert rocks into small pieces.

This method is used when hand rocks having no fissures or cracks are to be broken down into small pieces.

Stone obtained by blasting is usually of small size, and they are used as ballast in railway, aggregate for concrete road metal. Etc.

The following tools are required in the process of blasting. Dipper, Jumper, Priming needle, Scraping spoon, and Tamping bar.

The following materials are required in the process of blasting.

- A detonator is in the form of a copper cylinder, closed at one end. It contains 6 to 9 gm of culminating of mercury. It is used when dynamite is used as an explosive and is fired either by a fuse an electric spark.

- Explosive adopted and are generally blasting powder and dynamite. Blasting powder is also known as gun powder. It is a mechanical mixture of charcoal, saltpeter, and sulfur.

- Dynamite consists of 25% of sandy earth saturated with 75% of nitroglycerine. It is in the form of a thick paste.

- Fuses are required to ignite the explosives. They are in the form of cotton rope with a core of continuous thread of fine gun powder.

Also, read: Introduction of Gantry Girder | Load on Gantry Gutter | Type of Load on Gantry Gutter

Selection of a Site for Quarrying of Stones

- Available of tools, materials, and labour.

- Transportation facilities.

- Geological data.

- Quality of stone

- Quantity of stone

- The clean water source should be available near the quarry site.

- The site should be far from permanent structures like bridges, dams, etc. because the vibrations due to blasting in the site may cause harm to them.

- The non-living area should be available to dump the refuse obtained in quarrying.

- A proper drainage facility should be available.

- Geological information on the site should be read.

Methods of Quarrying

- Digging or excavating.

- Wedging.

- Heating.

- Quarrying with Channeling Machine.

- Blasting.

Quarrying Process for Natural Stones

Quarrying is the process of extracting natural stones from the earth’s crust for use in construction, decoration, and various other applications. It involves several stages and techniques to extract, process, and transport the stones. Here’s a general overview of the quarrying process for natural stones:

- Exploration and Site Selection: Quarrying begins with the identification of potential stone deposits. Geologists and surveyors study the geological formations and identify areas with suitable stone resources. Factors such as stone quality, quantity, accessibility, and market demand are taken into consideration during site selection.

- Clearing the Land: Once a suitable site is identified, vegetation, topsoil, and other debris are removed to expose the stone deposit. This clearing process ensures easy access to the stones and prepares the site for further operations.

- Drilling and Blasting: Quarrying often involves the use of explosives to break the stone into manageable sizes. Holes are drilled into the rock formation using specialized equipment. Explosives are then placed in these holes and detonated, fracturing the stone into smaller pieces. This process is carefully controlled to minimize the impact on the surrounding environment and neighboring structures.

Quarrying of Stones Methods

Methods of quarrying include:

- a) Digging – This method is used when the quarry consists of small & soft pieces of stones.

- b) Heating – This method is used when the natural rock bed is horizontal and small in thickness.

- c) Wedging –This method is used when the hard rock consists of natural fissure.

Quarrying of Stones Process

Development of most modern rock quarries involves stripping the overlying soil and weathered rock to get to the hard rock underneath. This is then worked in a ‘bench’ system, removing the rock in layers that can be returned to year after year as the quarry is developed.

Quarrying of Stones Equipment

The quarrying of stones refers to the process of extracting stones from natural rock formations or beds. It is an essential activity in the construction industry as stones are used for various purposes such as building materials, road aggregate, landscaping, and decorative purposes. Quarrying requires specialized equipment to ensure efficient and safe operations.

Quarrying of Stones Hazards

Quarrying of stones involves various hazards that can pose risks to workers’ safety and health. It is important for quarry operators and workers to be aware of these hazards and implement appropriate safety measures to mitigate the risks. Here are some common hazards associated with quarrying of stones:

- Rock Falls and Collapses: Quarrying activities can destabilize rock formations, leading to the risk of rock falls and collapses. Loose rocks or unstable slopes can pose a significant hazard to workers, causing injuries or fatalities. Proper slope stabilization measures, such as scaling and rock bolting, should be implemented to minimize the risk of rock falls.

- Dust Exposure: Quarrying of stones generates a significant amount of dust, which can lead to respiratory issues such as silicosis, a lung disease caused by inhalation of crystalline silica dust. Prolonged exposure to dust can also cause other respiratory problems, eye irritation, and skin conditions. Dust suppression techniques, such as using water sprays and dust collectors, should be employed to reduce dust levels and provide adequate ventilation in work areas.

- Noise Pollution: Quarrying operations can produce high levels of noise, especially during drilling, blasting, and crushing activities. Prolonged exposure to excessive noise can cause hearing loss and other hearing-related problems. Workers should wear appropriate hearing protection, and noise control measures like enclosing noisy equipment or using noise barriers should be implemented to minimize exposure to high noise levels.

Quarrying Meaning

Quarrying refers to the process of extracting natural resources, specifically minerals, rocks, or stone, from the earth’s surface. It involves the removal of materials from a quarry or an open-pit mine, typically through the use of heavy machinery, explosives, or drilling and cutting techniques.

Types of Quarries

Types of Quarries

- Hard rock.

- Natural sand.

- Natural sand and gravel.

- Sandstone (building stone and sand)

- Marine/ocean.

- Limestone.

What Is Quarrying of Stone?

Quarrying is the process of removing rock, sand, gravel or other minerals from the ground in order to use them to produce materials for construction or other uses. So, a quarry is any such working on the surface of the earth where minerals are extracted.

What Is Quarrying?

Quarrying is the process of extracting natural resources, typically minerals, rocks, or stone, from the earth’s surface. It involves the removal of materials from a quarry or an open-pit mine, using various methods such as drilling, blasting, cutting, or excavation.

Describe a Method Used to Remove Rock Blocks?

One method commonly used to remove rock blocks in quarrying is the use of wire saw machines. Wire sawing is a technique that involves using a diamond-studded wire to cut through large blocks of stone or rock. It is particularly useful when dealing with hard and dense materials such as granite and marble.

Quarrying of Stones

Quarrying is the extraction of stones from natural rock surfaces. Stone quarrying is not the same as mining. Mining is only done underground, whereas quarrying is done on the exposed surface of natural rocks to the sun’s light. Stone quarrying is typically done in hilly areas with a plentiful supply of stone.

Marble Mining Process

Mining marble from a quarry involves creating a bench wall, which requires synthetic diamond wire and diamond-tipped drills to separate the rock to form a vertical plane. This involves drilling holes in the marble from the top of the quarry and lining up another drill hole from the side.

How to Quarry Stone?

The quarrying process begins by drilling a series of intersecting holes into the quarry walls. Diamond-tipped wires are fed into the holes creating a continuous loop. Powered by a motor the wire spins until the desired block is cut.

Like this post? Share it with your friends!

Suggested Read –

- West Point Bridge Designer

- What Is Plaster | Type of Plaster | Defects In Plastering

- Difference Between One Way Slab and Two Way Slab | What is Slab

- What are Traps | What Does Trap do | 12 Types of Traps In Plumbing

- Introduction of USCS | USCS Classifies Soils into Two Broad Categories

- What Is Structural Settlement | Causes For Structural Settlement | What Is Soil Settlement & Foundation Structural Settlement

Originally posted 2023-05-31 12:45:27.

Leave a Reply