Introduction of Movement Joint In Concrete

Important Point

All buildings move, especially when considering factors like expansion joint in concrete. If there is no restraint to movement, then it can occur freely without the development of internal stresses that could lead to damage.

In practice, some restraint will always be present, even in the smallest building element.

The concrete designer is concerned to identify sources of movements, assess their magnitude, and then to consider whether the structure will be damaged if and when movements occur.

If so, joints offer one solution for avoiding or controlling such damage. (Other solutions include the use of prestressing to prevent or limit tensile stresses, and the use of additional reinforcement to control cracking.)

Failure to provide movement joints where needed may lead to the structure making its own – by cracking.

Also, read: What Does Parapet Mean | Types of Parapet Wall | Uses of Parapet Wall

Why Required Movement Joint In Concrete?

Sources of movement can be external or internal.

External sources include:

- Temperature variation

- Loading (Static and Dynamic, Including Gravity, Wind, and Earthquakes)

- Atmospheric humidity changes

- Ground movements (Settlement, Consolidation, Shrinkage, Heave, etc.).

Sources of movement also arise from within the concrete itself.

These are principal:

- Early-age thermal movement from the rise in concrete temperature during cement hydration and, more significantly, the subsequent drop back toward ambient temperature

- Irreversible drying shrinkage

- reep under stress.

Also, read: Hip Roof Vs Gable Roof | What Is Gable Roof | What Is Hip Roof

Useful Article for You

- Why Do They Put Gravel on Roof

- Why Are Blocks Placed in Trenches

- Why Is Knowing Properties of Matter Important for Engineers?

- Why Are They Called Cinder Blocks

- Why Is It Called a Flight of Stairs

- Why Does Mortar Crack When Drying

- Why Is Quicksand Called Quicksand

- Why Is It Called a Pony Wall

- Why Is an I Beam So Strong

- Why Does Concrete Get Hot

- Why Are Plasticizers Added to Polymers

- Why Are My Tiles Popping Up

- What Are 4 Types of Arches

- Why Do They Put Lines in Concrete

- Why Is It Called the Golden Gate Strait

- Why Are Arches So Strong

- Why Is Fly Ash Used in Concrete

- Why Does Concrete Have Lines

- Why Is Bamboo So Strong

- Why Is Cedar Wood Good

- Why Are Washers Called Washers

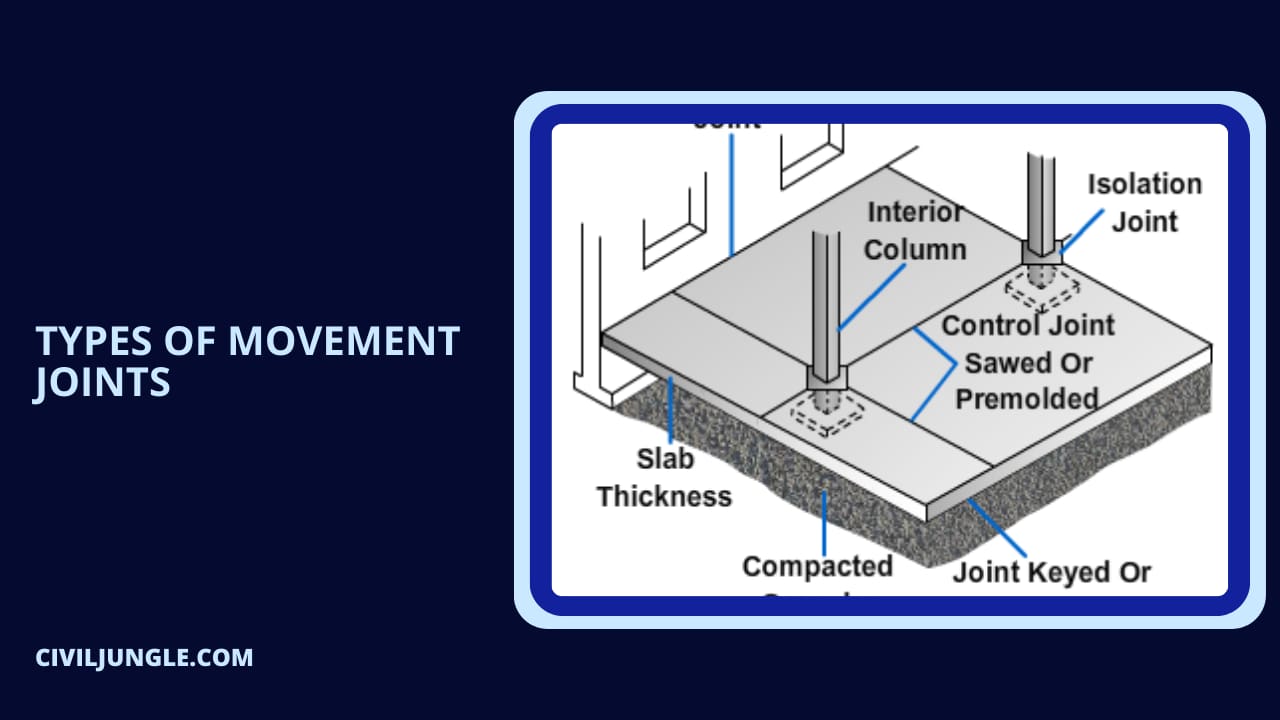

Types of Movement Joints / Joints in Concrete

- Isolation Joints / Free Joints.

- Free Contraction Joints.

- Partial Contraction Joints.

- Tied Partial Contraction Joints.

- Debonded Partial Contraction Joints.

- Expansion Joints.

- Hinged Joints.

- Sliding Joints and Bearings Joints In Concrete.

- Seismic Joints.

#1. Isolation Joints / Free Joints In Concrete:

Isolation Joints

As its name implies, this joint allows free translation and rotation in all directions. See the above figure. It is most commonly used in the following circumstances:

- In structures above ground level (particularly in roof slabs and exposed soffit slabs) to accommodate temperature variation movements.

- Temperature variations are both of smaller magnitude and slower to occur below ground level, due to the ‘heat sink’ effect of the subsoil and reduced exposure to climatic extremes.

- In structures generally, to accommodate differential ground movements, especially when adjacent elements or blocks exert different levels of bearing pressure and/or have foundations with different settlement characteristics, such free movement joints are also known as settlement or isolation joints.

Also, read: Grades of Cement | Types of Cement Grades | Which Grade Cement Is Used for Slab

#2. Free Contraction Joints In Concrete:

Free Contraction Joints

This type of joint is formed and has no initial gap. It is for use where the movement will lead to opening of the joint only (see above figure ).

It is most commonly used in water-containing structures to deal with early-age thermal movements and irreversible drying shrinkage, where no load transfer or equalizing of deflection in the plane of the joint is required.

Such a joint may be applicable in circumstances where some expansion may occur, for example, due to temperature rise – but only when this follows and is of lesser magnitude than initial contraction.

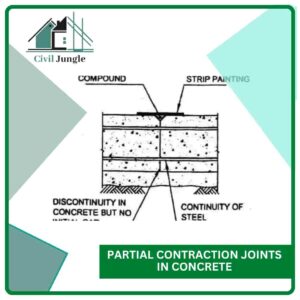

#3. Partial Contraction Joints In Concrete:

In this type of contraction joint, reinforcement continues across the butt joint in the concrete, although it is either reduced in section or debonded so that the joint will indeed be able to serve as a plane of weakness at which contraction can occur.

Steel is provided to ensure that shear loads can be transferred across the joint and/or when equalizing of deflection in the plane of the joint is required.

Such joints are provided to deal with early-age thermal movement and irreversible drying shrinkage in water-containing structures, retaining walls, and large ground-bearing slabs.

There are two basic variants – the tied and the debonded joint. They may be formed by placing concrete either side of the joint in two pours, or alternatively, the concrete is placed in a single pour.

In the latter case, separation at the joint is achieved by the use of a crack-inducing strip and/or sawing a groove in the concrete surface.

Useful Article for You

- Difference Between Silt and Clay

- Difference Between Tension and Compression

- Difference Between Footing and Foundation

- Types of Cranes

- Types of Stones

- Types of Curtains

- Types of Shovels

- Types of Vaulted Ceilings

- Types of Porches

- Types of Gable Roofs

- Types of Plasters

- Difference Between Azimuth and Bearing

- Difference Between Pile and Pier

- Difference Between Nail and Screw

- Difference Between Truss and Rafter

- Difference Between Steps and Stairs

- Difference Between Timber and Lumber

- Difference Between Fine and Coarse

- Difference Between Gunite and Shotcrete

- Difference Between Basalt and Granite

#3.1. Tied Partial Contraction Joints In Concrete:

Tied Partial Contraction Joints

- The tied contraction joint has a reduced area of reinforcement across the joint.

- This assists shear transfer and prevents overall free opening of the joint while permitting relief of early-age thermal movements and shrinkage on the surface.

- This reduces the possibility of unwelcome surface cracking from such causes occurring elsewhere.

- This type of joint is much used between adjacent pours in water-containing structures and large ground-bearing slabs.

#3.2. Debonded Partial Contraction Joints In Concrete:

Debonded Partial Contraction Joints

- In this variant, some reinforcement is provided across the joint as for the tied contraction joint.

- It is debonded on one side of the joint so that unrestrained contraction can occur across the full thickness of the section to allow early-age thermal movements and shrinkage to occur.

- This type of joint is used less often than tied contraction joints.

- It is most commonly used in large ground-bearing floor slabs, roads, and hard-standing.

- The reinforcement is usually provided in the form of dowel bars.

Also, read: What Is Unit Weight | What Is Density | What Is Unit Weight Material | Unit Weight Building Materials

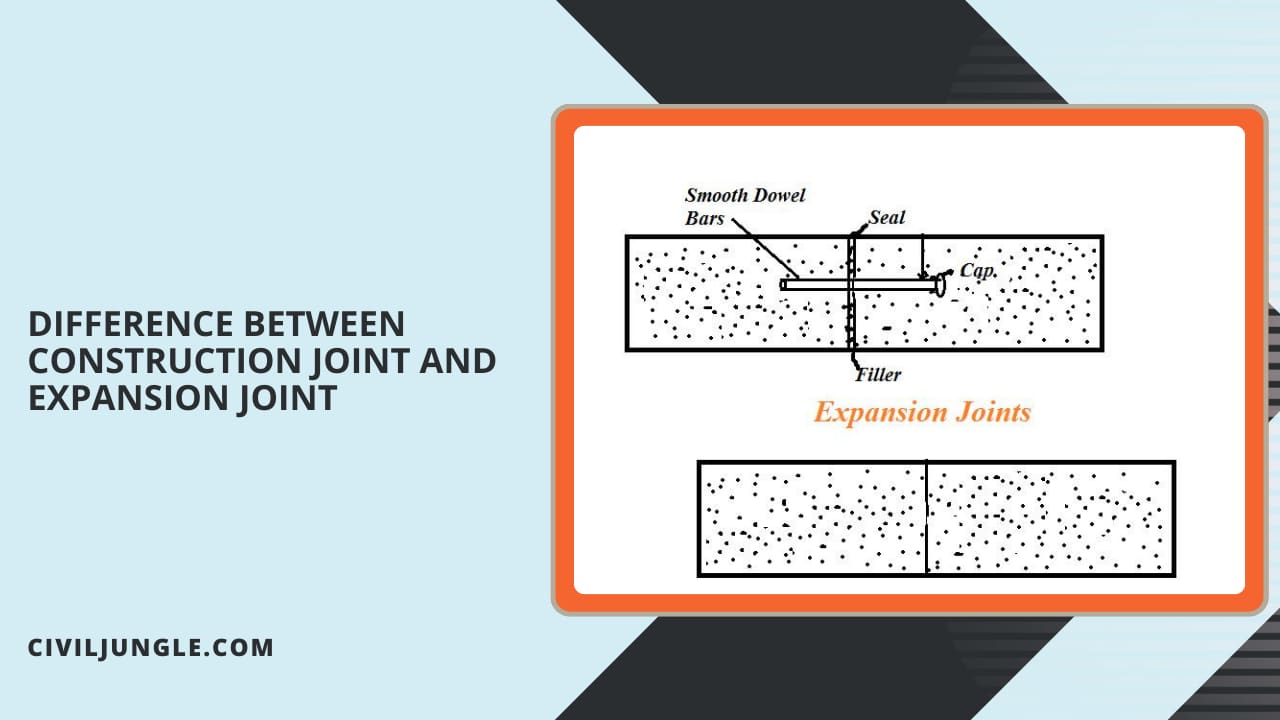

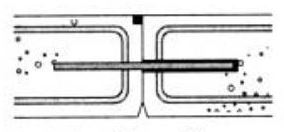

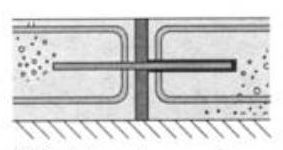

#4. Expansion Joints In Concrete:

This term, often referred to as expansion joint in concrete, is commonly, but loosely, used to describe any formed gapped joint, whatever its structural role and irrespective of whether opening or closing movements are expected.

Such a joint is intended to allow expansive movement to occur freely. It may be free (See above figure free expansion joints) – in which case it is essentially a free movement or isolation joint – or have reinforcement (See below figure reinforced Expansion joints) to transfer shear and equalize deflections.

Reinforced Expansion Joints

The reinforcement, if present, must be debonded to allow free axial movement.

This type of joint is used for elements exposed to significant temperature variation (notably solar gain) such as roof slabs, footbridges, and ground-bearing slabs outdoors.

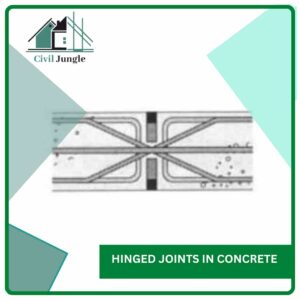

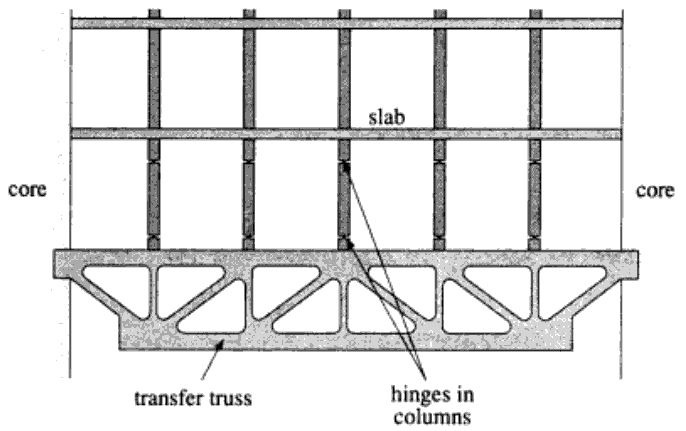

#5. Hinged Joints In Concrete:

Hinged Joint

The hinged joint (See above figure) is more common in bridges, particularly arches, than in building structures.

It has a narrow concrete throat with concentrated reinforcement to allow rotational freedom (minimizing moment transfer) while providing shear and axial load transfer and equalizing deflections across the joint.

It has been used in a few structures to provide effectively ‘pinned’ concrete connections, for example, to minimize potentially damaging horizontal shear forces in the lowest of column carrying floors down to a progressively – post-tensioned long-span transfer (See below figure)

Hinged Joints

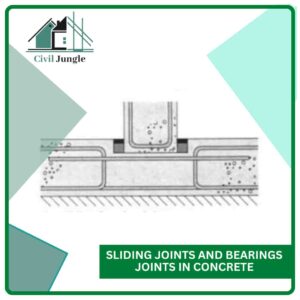

#6. Sliding Joints and Bearings Joints In Concrete:

Sliding / Bearing Joints

Sliding joints and bearings are generally used in precast concrete structures and in larger civil engineering structures such as bridges, although sliding joints are also found at the wall-floor and wall-roof junctions in water-retaining structures.

Such joints are similar to free movement joints except that loads are carried from one element to the other by bearing.

This may be achieved either directly across smooth concrete surfaces or (preferably, to minimize friction) by purpose-made bearings or membranes designed to allow the required freedom of movement while still transmitting loads.

Such bearings, suitably designed, can also provide acoustic and vibration isolation (e.g., for a hospital built next to a railway line) and base isolation to protect structures in seismic zones.

A common example of a sliding joint is the slip membrane provided under a ground-bearing slab to allow shrinkage contraction. This is discussed in Deacon”.

Figure sliding and bearing joints show a typical sliding joint at a floor-wall junction in a water-retaining structure.

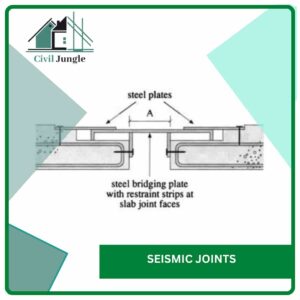

#7. Seismic Joints:

Earthquakes can cause large movements to occur in buildings and other structures. This calls for particular attention where open movement joints have been provided; these joints will have to be of sufficient width to accommodate the cumulative anticipated movement across the joints.

This may be 100mm or more, which is well beyond the capability of any orthodox joint sealant or gasket. Choosing a suitable bridging material for such joints may be complicated by the need to accommodate pedestrian or vehicular traffic.

Also, read: What Is Composite Masonry | Type of Composite Masonry

Construction Joint Vs Expansion Joint

| Sr.No. | Construction Joint | Expansion Joint |

| 1 | A construction joint vs control joint occurs when there are multiple concrete placements. | An expansion joint is used in concrete and steel. |

| 2 | It can occur between different days of concrete placements. | An expansion joint allows the concrete or steel to expand or contract with daily temperature variations. |

| 3 | If you don’t allow this, you may get crake to develop in concrete | If you don’t allow this, you may get buckling, or spalling, or total failures. |

| 4 | Type of Construction Joint 1. Free Contraction Joints 2. Partial Contraction Joints 2.a. Tied Partial Contraction Joints 2.b. Debonded Partial Contraction Joints |

Type of Expansion Joint 1. Free Expansion Joints 2. Reinforced Expansion Joints |

Concrete Expansion Joint

Expansion joints are put in place before the concrete is poured. Expansion joints are used to allow the slab to move and not put stress on whatever it abuts. These joint are placed where a slab meets a building, where a slab meets another slab, and where a pool deck meets the coping.

Expansion Joint in Building Construction

In building construction, especially when considering the foundation expansion joint, an expansion joint is a mid-structure separation designed to relieve stress on building materials caused by building movement induced by: thermal expansion and contraction caused by temperature changes, sway caused by wind. seismic events.

Types of Expansion Joints in Buildings

They include joints for small movement (EMSEAL BEJS, XJS, JEP, WR, WOSd, and Granor AC-AR), medium movement (ETIC EJ, Wd), and large movement (WP, ETIC EJF/Granor SFEJ). Modular expansion joints are used when the movements of a bridge exceed the capacity of a single gap joint or a finger type joint.

Joints in Buildings

The construction joint, control joint, expansion joint, settlement joint, and the seismic joint are some of the common types of joints in building construction. Building joints allow for movement along the depth of the structure.

Expansion Joint Between Buildings

They are required to break the bond between building sections to ensure the sections can separate. Since the material is compressible, it can accommodate the movement of adjacent materials.

When Should Expansion Joints Be Used?

Expansion joints are required in large ducted air systems to allow fixed pieces of piping to be largely free of stress as thermal expansion occurs. Bends in elbows also can accommodate this.

Expansion Joint in Building

Expansion joints occur through all parts of a structure to provide complete separation – through floors, walls, ceilings, and roofs (interior & exterior).

How Many Expansion Joints Are in a Building?

Expansion joint spacing is dictated by the amount of movement that can be tolerated, plus the allowable stresses and/or capacity of the members. As with contraction joints, rules of thumb have been developed. These range from 30 to 400 ft (9 to 122 m) depending on the type of structure.

Keyed Concrete Joint

A key joint is a pre-manufactured device used to create control joints in concrete structures. As freshly-poured concrete begins to dry, it tends to shrink or contract. This contraction can lead to cracks or breaks in the surface of the concrete, or in tiles and other floor finishes installed over the slab.

Expansion Joint in Construction

Expansion joints are separations between structures, simply gaps, to allow them to move and reduce stresses that may occur. Often, these gaps are filled with an Expansion Joint System to fill in the void to ensure walkability, a complete building enclosure, waterproofing, and general serviceability of the structure.

Is Expansion Joint a Construction Joint?

An expansion joint, often debated in the context of construction joint vs control joint, separates the building components above foundation such as walls, floors, roofs (except wooden roof) into several separate parts, so that the building can expansion or contraction in horizontal direction.

What Is the Purpose of Expansion Joints in Concrete?

A concrete expansion joint – or control joint – is a gap which allows the concrete to expand and contract as/when the temperature changes. It forms a break between the concrete and other parts of a structure to allow movement without causing stress, which can lead to cracking.

Like this post? Share it with your friends!

Suggested Read –

- Stone Joints

- Concrete Cantilever

- Steps of Construction

- Control Lines Construction

- Manufactured Sand Concrete

- Road Development Plans in India

- What Is Dry Pack Mortar | Advantages of Dry Pack Mortar | Disadvantages of Dry Pack Mortar

- Difference Between Whole Circle Bearing and Quadrantal Bearing | What Is WCB | What Is QB

- What Is Injection Grouting | Types of Injection Grouting | Different Types of Grouting Materials

- What Is Hempcrete | Hempcrete Blocks | Advantages & Disadvantages of Hempcrete Blocks | Applications of Hempcrete

- What Is Hard Hat | Hard Hat Colour Definition | Different Hard Hat Colour Codes | Types of Safety Helmets | Classification of Hard Hats

Leave a Reply