The Best Concrete Mix for Countertops

Important Point

Concrete is a fantastic material used worldwide to build everything from residential homes to large-scale buildings, damns, and bridges.

But it’s also used for smaller projects like cast statues, steps, walkways, and countertops.

The world changes and technology advances and human advancement grows with it.

So keeping up with the latest trends and innovations isn’t always easy. Because of these factors, conducting some study before investing in something to benefit the long term is essential.

Concrete is one of the more popular countertop options that are on trend for 2021. These countertops provide a studding modern-industrial aesthetic and are customizable to suit various kitchen styles.

However, suppose you desire the aesthetic of concrete but could do with less maintenance.

In that case, Caesarstone’s premium quartz countertops come in several premium styles that mimic concrete, such as 4004 raw concrete and 4003 sleek concrete.

This is a huge benefit compared to stone which has size limitations. But you have to use the right concrete mix for countertops.

Many concrete countertop pros have experimented with their mixes over the years, fine-tuning them to perfection to achieve consistent, reproducible results.

Some major manufacturers of bagged concrete and mortar mixes now also offer formulas developed specifically for countertops.

The best concrete mix for countertops is one with high compressive strength, smaller, rounder stones, and some flexibility.

If you prefer mixing your batch, I use a formula: 1 part Portland cement, 2 parts sand, and 3 small round stones.

Use just enough water to activate all the cement, not a drop. Mix in some chemical additives that increase strength and flexibility.

If the countertop sections are long, I use fiber reinforcement, micro rebar, or wire mesh.

Also, Read: Best Concrete Mix for Driveways

What Type Of Concrete Is Best For Countertops?

Most standard concrete mixes are designed for structural jobs like pouring footings, a sidewalk or setting a fence post.

The best concrete mixes for countertops use smaller stones which provide a smoother surface and additives to increase strength and flow.

This means the concrete will penetrate the corners and not hold as many air bubbles.

- Concrete countertop mixes use additives to increase strength and reduce cracks.

- Other additives are used to make the concrete flow better. This makes it easier to jig the concrete and release air bubbles.

- To build the best countertops, you need the right concrete mix. You have two main options, buy pre-mixed concrete or make your batch.

- A good mix for concrete countertops should.

- Have a law water-cement ratio to prevent shrinkage cracks.

- Provide high compressive strength.

- Be easy to work with.

- Have good surface quality.

- If this is your first time making concrete countertops, I recommend buying premixed ones. Just use the correct amount of water and pour it into the forms.

And if you are experienced with concrete countertops and need something special, you can mix your own.

Mixing your concrete is the best way to control how it’ll perform during the job and after the concrete has hardened.

Concrete Countertops Need Very Strong Concrete

Strength is essential when creating concrete countertops because the slabs are typically large but thin, averaging just two inches thick.

At this thickness, concrete is prone to cracking. But quite concrete mix uses additives that increase strength and resist cracks.

Using a concrete mix with a higher PSI provides better defense against cracks.

- Three days after pouring a counter with quikrete countertop mix, the compressive strength is already at 2,000 pounds per square inch (PSI).

- At seven days, it reaches 4,000 ps.

- At full cure (28 days), the countertop slab will reach 6,000 PSI.

The average concrete mix with a PSI of 3500 would crack under this usage.

Concrete countertops will be used in your kitchen, bar, grill area, or bathroom. It needs to resist spills and everyday wear and tear.

Useful Article for You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is a Frame Structure

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is Mdf Mean

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Overhang

- Cracking Moment Formula

- What Is Sand Blasting

- What Is a Span Bridge

- What Is a Soil Stack

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- What Is Pedestal

- Super Plasticizer Admixture

- What Is Plumbing Fixtures

- What Is a Highway Flyover

- What Is Slab Construction

- What Is Calacatta Quartz

- What Is Auxiliary View

- Sheepsfoot Roller

- Live Load Vs Dead Load

- What Is 1 Flight of Stairs

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- What Is a Moment Frame

- Arch Foundation

- What Is a Stair Landing

- What Is Stone Masonry

- What Is a Spandrel Beam

- What Is Pier and Beam Foundation

- What Is Levelling

- What Is a Pile Cap

- What Is a Mat Foundation

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is Modulus of Rupture

- What Is a Flush Door

- What Is a Weep Hole

- What Is Residential Construction

- What Is Cinder Block

- What Is a Concept Sketch

- What Is Tie Beam

- What Is the Best Foundation for a House

- What Is Oblique Drawing

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is a Monolithic Slab Foundation

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is False Ceiling

- What Is a Parapet Wall

- What Is a Caisson in Construction

- What Is a Tremie

- What Is Rebar in Construction

Countertop Concrete Needs Good Workability

The best concrete countertop mixes are workability, a.k.a. Flow. This is one of the reasons why a standard concrete mix doesn’t work.

Pour concrete in a two-inch thick form; it has to flow into the tight 90-degree angle corners and edges.

And if it can’t sit tight to the edge, the countertop won’t look very good. Because of bad flow and large rocks, standard concrete can’t produce as sharp an edge as a countertop mix can.

A precast concrete countertop from your shop to an installation site knows that concrete is heavy.

And it’s just the nature of the beast. Precast concrete countertops are typically made 1.5” thick and weigh 18 pounds per square foot.

A pre-mixed concrete countertop mix like quiet. It’s super strong and has a great flow. However, if you went to Create your mix, buy an additive that adds strength and another that increases flow.

Bubbles are another issue with concrete countertops if you want a smooth, hard surface finish.

The mix has to have a good flow. Concrete mixes are used to make countertops. The result is bubbles and a less-than-desirable surface finish.

Also, Read: How to Mix Quikrete Concrete: A Step-by-Step Guide

Quikrete Countertop Mix

The mix creates a smooth concrete surface that can be polished to a beautiful sheen without cracking.

It contains a smaller aggregate and a super-plasticizer additive, forming a dense and smooth countertop.

The mix is also self-consolidating, meaning it flows into the edges and corners of the form without a lot of vibrating.

Quickrete countertop mix is a specially formulated flowable high-strength concrete mix for pre-cast and cast-in-place concrete countertop applications.

- Super-plasticizer additives provide a flowable mix at a low water/cement ratio.

- High-flow formula minimizes the need for mechanical vibrations.

- Reduce-shrinkage formulation.

- High compressive strength at 6000 PSI.

- Good workability.

- $20 per 80 lb. bag.

- Forms can be removed in just 18 hours which makes countertop jobs faster.

Available in:

80 lb. (36.2 kg) bags

Compressive strength (ASTM C 109 modified):

1day – 2000 PSI (13.8 MPa)

7 days – 4000 PSI (27.6 MPa)

28 days – 6000 PSI (41.4 MPa)

It’s great for pouring precast and cast-in-place kitchen and bathroom countertops.

It’s a very durable mix that is designed specifically for countertops. It has very high strength and additives, making it flow better than a standard mix.

This is handy because you don’t need to vibrate it that much to release air bubbles.

I almost always use this premix unless I need a lot of concrete for a huge countertop job.

Moon Decorative’s EnCounter Concrete Countertop Mix

As concrete countertops become more mainstream, many professionals and DIYers are seeking a better alternative to the “mix your own” formulations and are choosing to go with more proven, consistent pre-packaged concrete countertop mixes.

Moon decorative’s encounter mix blends white limestone rocks, well-graded aggregates, cement, and performance-enhancing admixtures to minimize shrinkage and cracking, improve the finish, and achieve strength topping 8000 psi after 28 days.

It’s great for large cantilevered countertops or long single spans.

- Packaged in 50-pound bags.

- Available in white or gray.

- It can be colored with liquid pigments.

- 8870 psi in 28 days without additional admixtures.

- $40.98 per bag. This is more than double the cost of a quikrete countertop mix.

- Lower water content minimizes curling.

Benefits Of Concrete Countertops

Concrete countertops have a beautiful, modern look that can update just about any space. A versatile look that fits in with any color scheme or house design.

Customization:

concrete countertop mix can be cast into any shape and size. And it’s easy to drill holes in sinks and soap dispensers.

Colors:

concrete’s natural color is a cool gray or subtle white; color can be added when mixing or spread on top to create various shades and hues.

Added features: the countertop’s surface can be enhanced with embedded stones, marble, glass chips, tile, or veining.

And once you pour the countertop, experiment. To create all sorts of unique surface effects.

Diy:

can you imagine the average homeowner cutting and setting these own marble? But the average handy homeowner can pour concrete countertops. It’s quite easy to use quicker countertop mix and form kits you can buy online.

Affordable:

concrete countertops are considered a high finish similar to quartz, quartzite, and marble. But they’re a lot cheaper.

Durability:

Concrete countertops built using the right concrete mix, like quicker countertop concrete, are extremely durable.

Cleaning:

if you seal your concrete countertops properly, they’re very easy to keep clean.

Useful Article for You

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Cmu Wall Meaning

- Gradient Road

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- Well Points

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

- How Heavy Is Dirt

- Tender Meaning in Architecture

- Dark Olive Green House

- Cast in Place Concrete

- Lean to Roof

- How Tall Is an Average Door

- Grade Beam Foundation

- Window Sill Height

- Concrete Cold Joint

- Types of Traps

- Types of Pipe

- Wood Supporting Beams

- Finishing Plaster

- Concrete Wall Finishes

- Home Depot Scrap Wood

- Lvl Beam Size Calculator

- Structural Shell

- Curb Types

- Msand

- Optimum Dry Meaning

- Disadvantages of Low-E Glass

- Bridge Abutment Definition

- Plumbing Joints

- Build Materials List

- Composite Masonry Wall

- Is Cedar a Hardwood or Softwood

- Modified Proctor Test

- Construction Joint Vs Control Joint

- Physical Properties of Sand

- Sugar in Concrete

- Crane Machine Construction

- Types of Gable Roofs

- Different Types of Walls

- Door Frame Types

- How Much Does 55 Gallons of Oil Weigh

- Dog Leg Stairs

- Concrete Salt Finish

- Westpoint Bridge Builders

- Types of Porches

- Hempcrete Disadvantages

- Roof Pitch Types

- Types of Weirs

- Asphalt Floor

- Dutch Roof

- #6 Rebar Weight Per Foot

- Prizmatic Compass

- Bond Break Concrete

- Poured Concrete Wall Cost Calculator

- How Many 60 Lb Bags of Concrete in a Yard

- Wood Fence Post Spacing Chart

- Fly Ash Brick

- Falsework

- Design of Building Structures

- Topping Slab

How To Turn Regular Concrete Into A Countertop Mix?

Quickrete countertop mix is my go-to best concrete countertop mix because everything’s been done for me.

All the ingredients, ratios, and additives are already there, so I don’t have to worry about anything.

The brute strength of concrete has made it the go-to building material for various outdoor installations, driveways, walkways, and patios.

But some love concrete not only for its high durability and low maintenance but also for its distinctive look.

Z liquid- Crete from concrete countertop solutions: it’s described as an exclusive blend of additives and ultra-fine fibers that transform a 60 lb. bag of standard concrete into a high-strength flowable mix.

Designed for cast-in-place countertops, it produces a high-strength fiber-reinforced countertop that’s easy to trowel smooth.

Counter- Flo from fritz-pack: it’s a mixture of water reducers and mineral admixtures specially designed for use in the making of concrete countertops.

Simply add 1 level scoop of counter-flow per each 80-lb bag of concrete.

Counter-flow modifies regular concrete, making it easier to pour and stronger, reduces water shrinkage cracks, and produces a smoother finish.

Also, Read: 10 Free Outdoor Fireplace Construction Plans

Indoor Or Outdoor Concrete Countertops?

Concrete is a great indoor and outdoor material. Most concrete countertops are built indoors but are also great for outdoor kitchens and bar areas.

Unlike many building materials, concrete tolerates climate-controlled environments and some temperature and humidity fluctuations.

Concrete countertops are often the focal point of indoor kitchens. They’re equally at home out on a deck or patio.

And they’re great for more than just food prep. Imagine using a countertop mix to create a beautiful outdoor countertop to serve as a sturdy work surface for all your potting and transplanting needs to the concrete countertop.

The best concrete mix for concrete countertops is the same, no matter where you install them, indoors or outside.

No additional additives or ingredients are required, and the forms are the same. They use a good quality concrete sealer to protect against water damage and stains.

How Much Concrete Do I Need For A Countertop?

An 80lb bag of quikrete countertop mix yields approximately 0.6 cubic feet of concrete.

For example, making a 2-foot by 3-foot countertop approximately 2 inches thick requires two 80-pound bags, 360-pound bags, or 440-pound bags of concrete.

Use these free concrete calculators to estimate how much concrete you’ll need for slabs, footings, or columns.

It is a good idea to overestimate the amount of concrete needed so you won’t fall short on the job site.

Many concrete calculators are available for free online to help you make the calculations.

Simply input the length, width, and thickness of your countertop, and they’ll tell you how many bangs you need.

Also, Read: Glulam Weight Calculator

How Much Do Concrete Countertops Weigh?

The concrete countertop is very heavy. A small 2-foot by 3-foot countertop that’s 2 inches thick weighs around 150 pounds when complete.

And most concrete countertop jobs are poured in place, so you won’t have to carry them around.

The normal one-and-a-half-inch thick concrete slab weighs around 18.75 pounds.

However, depending on the concrete used to make the slab, concrete slabs can weigh much lighter. However, this material is less durable and more prone to cracking.

Can You Add Color To the Concrete Countertop Mix?

Color can be applied throughout the entire mix with integral pigments or to the surface of cured concrete with stains or dyes.

There are different brands of pigments, stains, and aggregate colors, so concrete countertops will always be unique.

The best part about coloring concrete is that if you do it correctly, there is no need to tear or damage your concrete and have to repour it.

And these processes will give you great color without harming or weakening your concrete. It comes in two basic forms.

Liquid: liquid colors are added to the wet concrete mix before it’s poured.

The color can be thoroughly mixed from a uniform color throughout the concrete or lightly mixed to create a marbled or veined appearance.

Powder: powdered coloring can be spread on top of the concrete countertop slab as it’s curing. This is just a surface coloring similar to the look of a stamped concrete patio.

Also, Read: How Many Cubic Feet in a Bag of Concrete?

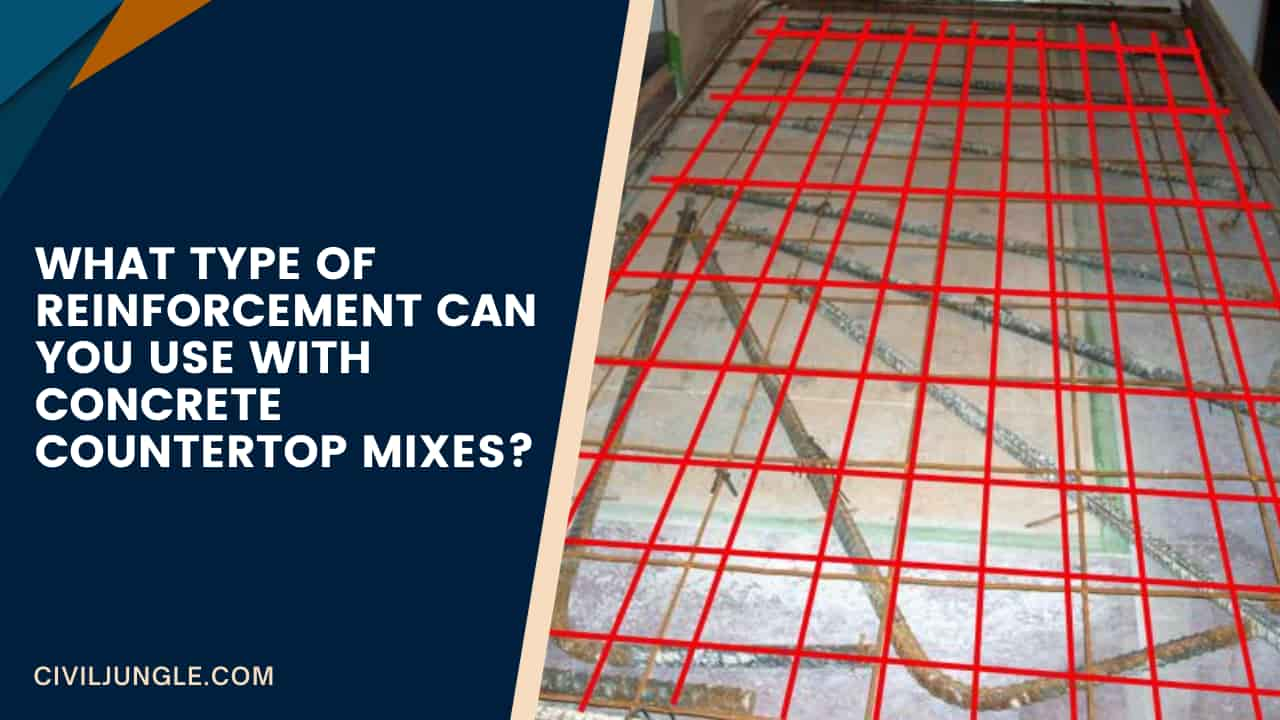

What Type Of Reinforcement Can You Use With Concrete Countertop Mixes?

Concrete countertops are not supported by a subgrade, as are floors and other slabs.

They are like cantilevers and must be reinforced to limit structural cracking and ensure sufficient tensile strength and ductility.

Additional reinforcement adds even more strength and durability to the best countertop mixes.

Rebar: steel rebar can be used inside the concrete countertops to add strength, crack resistance, and durability. This is a great option when the slabs are especially long.

Wire mesh: this is a countertop reinforcement when the slabs aren’t that big. It strengthens the concrete, increases durability, and resists cracks. But it isn’t as strong as rebar.

Fiber: fiber is a good all-around reinforcement added to the wet mix. It strengthens the concrete itself from the inside.

Micro Rebar: micro steel rebar is another form of reinforcement that’s added into the wet mix. It’s stronger than fiber, and some say even stronger than raber.

What Forms To Use With Concrete Countertop Mix?

Some say you could make your concrete mix, but that takes time and patience.

The best form to use with concrete countertop mixes is melamine-coated particle board or plastic concrete countertop forms.

Melamine: Melamine is a water-resistant material that’s very smooth. It’s a strong material that, when screwed together, can hold the weight of poured concrete.

Plastic Forms: Factory-made plastic concrete countertop forms are sold in various shapes and sizes. Simply install them, pour the concrete, and then snap off the excess plastic.

Pro tip: after you’ve built your forms, apply a bead of silicone caulk to the inside joints.

Also, Read: Concrete Construction Tools for Construction Sites

How Much Water Do You Use With Concrete Countertop Mix?

Always add water to concrete slowly as you mix it. Concrete countertop mixes typically require a low water content.

Too much water will make weaker concrete, and it’ll be harder to work with.

The consistency you’re looking for is like oatmeal. You should be able to pick up the concrete with your hand and form it into a ball.

If the concrete is too wet to form or won’t hold the bold shape, you use too much water.

If you see powder in the tray, add a small amount of water and keep mixing until it’s all activated.

Note: Final water content should be 8-9 pints (3.8 – 4.3 L) per 80 lb (36.3 kg) bag of concrete.

Does Concrete Countertop Mix Form Bubbles?

The way to release air bubbles from the countertop concrete mix is easy. Pinholes are aggravating. These tiny holes in the concrete surface are formed by air bubbles trapped in the concrete.

Bubbles become pinholes when they form on the surface of the concrete during casting and when the concrete is ground or honed.

Simply tap or shake the forms as you pour concrete into them. Once the forms are full, continue to tap and shake the forms. The more you vibrate the forms, the smoother the sides will be.

Can You Sand Concrete Countertop Mix?

After removing the forms, I wet the concrete countertops with fine sandpaper and water.

Work out rough spots and edges with a wet sanding sponge. I like to use the same mix to fill voids as the rest of the countertop so the color will match.

Sanding the edges can create a slightly rounded corner, just like stone countertops.

Also, Read: Why Hairline Cracks in Concrete | Types of Cracks in Concrete

Does Concrete Countertop Mix Need To be Sealed?

Like most natural countertop materials, concrete is porous and needs to be sealed to prevent staining.

And depending on the sealant used, some discoloration and patina may develop —a chance outcome that’s appealing to some, and appealing to others.

Always wait the full 28-day curing time before sealing your concrete countertops. Bagged Concrete Countertop MixesBagged mixes offer simplicity and convenience as their key feature.

Casting: choose a mix that’s right for the casting, forming, and finishing methods you plan to use. Some mixes are stiffer and need mechanical vibration, while others have higher slumps and can simply be poured into the forms with little vibration.

Performance: bagged mixes are proprietary products, so they perform differently regarding compressive strength.

Concrete Countertop Maintenance

- Concrete countertops are strong, durable, scratch and water-resistant.

- Seal exterior countertops with Quikrete’s high gloss acrylic sealer once a year.

- Don’t use abrasive cleaners on concrete countertops. They could damage the sealer coat.

- Clean the countertop with a diluted solution of plain dish soap and water.

- Apply a food-safe wax on countertops that will be exposed to food.

- Always seal concrete countertops whether they’re installed inside or out

Countertop Concrete Mix Vs Regular

Remember: There’s no substitute for Concrete Countertop Mix. That’s because it has a special ingredient — super-plasticizer — that helps the mix flow better, and prevents shrinking, cracking and air bubbles.

Do I Need Rebar in Concrete Countertop?

“No material more than 3/16-inch in diameter should be used in a countertop less than 3 inches thick.” Michael Karmody, a founding partner of Stone Soup Concrete, agrees that rebar is only useful in a situation where you have a large volume of concrete.

How Thick Should Concrete Countertops Be?

HOW THICK ARE CONCRETE COUNTER- TOPS? Standard thickness is 1 1/2” with a minimum of 1 1/4” and maximum of 3”. Any thickness beyond 3” can be achieved using techniques to give the appear- ance of the desired thickness, yet still maintain weight and size within desirable limits.

Can I Use Quikrete 5000 for Countertops?

Quikrete 5000 is an awesome mix!

As for durability, I’ve had outdoor kitchen counters made from Quikrete 5000 sitting in the elements the last 5 years. They still look great.

Do You Need Rebar in Concrete Countertop?

Concrete countertops are not supported by a subgrade, as are floors and other slabs. They are like cantilevers and must be reinforced to limit structural cracking and ensure sufficient tensile strength and ductility.

Disadvantages of Concrete Countertops

Cons of White Concrete Countertops

- Cement is permanent. Cement is a popular choice as a countertop surface right now, but in ten years, it might feel dated and old, and removing them will be difficult.

- Concrete countertops scratch & stain easily.

- Sealing cement properly is difficult.

- Cement cracks.

What Are the Pros and Cons of Concrete Countertops?

Pros and Cons of Concrete Countertops

- Pro: Concrete is durable. The strength of the cement-and-sand mix alone has some hailing it as a rock solid (we had to) design choice.

- Con: But it can crack.

- Pro: Cracks can be fixed.

- Con: Concrete is susceptible to stains and scratches.

- Pro: So is basically everything else.

Can You Put Hot Pans on Concrete Countertops?

Do not place hot pots and pans directly on your concrete countertop. The sudden change in temperature can cause damage to the sealer on your countertop. Always use trivets and hotpads. Likewise, cutting directly on your concrete countertop should be avoided.

Can You Use Regular Quikrete for Countertops?

Before all else, do not use regular Quickrete for concrete countertops. Instead, make sure to choose concrete with a PSI of at least 6000.

Problems with Concrete Countertops

Prone to chipping and staining: Just like with other stone surfaces, concrete countertops can and will chip if you’re not careful. It can also crack and sustain scratches. Concrete is also porous, which means it will absorb any spills and can even see bacteria growth if it’s not properly sealed.

Are Concrete Countertops Expensive?

The cost of concrete countertops ranges from $65 to $135 per square foot. This price usually includes the countertop design, materials, construction, and installation. Concrete countertops cost is not in the material, but rather in the artisan’s skill and creativity.

How Much Concrete Do I Need for a Countertop?

To find the amount of concrete you need, use our concrete calculator or this simple volume formula: Length × Width × Thickness. Measure your project and multiply the dimensions to get cubic feet or meters. Divide by 27 to convert cubic feet to cubic yards.

How Much Do Concrete Countertops Weigh?

Concrete countertops are extremely heavy and weigh in at around 20-25 pounds per square foot. This often requires reinforcing cabinetry and flooring so they’re capable of bearing the load. Despite its common use, concrete is actually one of the more expensive countertop options.

How to Reinforce Cabinets for Concrete Countertops?

Reinforcement should start with the bases. If adjustable plastic legs support the cabinets, we remove the legs and replace them with frames made of a double thickness of 3/4-in. plywood. If the cabinets have integral kick frames, we reinforce those frames with 3/4-in.

How Thin Can You Make Concrete Countertops?

Glass Fiber Reinforced Concrete can go as thin as 3/4″ for the same kitchen countertop slabs that would need to be 1.5″ thick for precast. This instantly cuts the weight in half.

How to Reinforce Concrete Countertop?

Steel rebar and wire mesh

This wire has a tensile strength, making it ideal for reinforcing countertops. To be effective, steel reinforcing materials should be placed in the bottom half of the countertop slab. Sufficient concrete cover is required to prevent corrosion and rust stains.

Quikrete Countertop Mix Color

Countertop Mix is available in standard gray (-80) and as a light colored tint-base (-81) for use with QUIKRETE® Liquid Colors.

Concrete Countertop Mix Design

Wet Cast 50-50-38-11 Mix

- Sand, 50 lbs.

- Stone, 50 lbs.

- Cementitious material, 38 lbs.

- Water 11 lbs.

- Plasticizer (water reducing agent) – This admix is used to increase the fluidity of the material without lowering the strength.

- If you want to make higher strength material, use more of the plasticize and less water.

How to Fix Rough Concrete Countertops?

The first and most common method is to grind and polish using a wet polisher and diamond polishing pads (and possibly a diamond cup wheel, depending on the severity of the imperfections). You would begin with the lowest grit necessary and work your way up. Usually you will go up to at least 200 grit.

Like this post? Share it with your friends!

Suggested Read –

Leave a Reply