What Is Formwork?

Important Point

The construction of a concrete building requires formwork to support the slabs (horizontal formwork) as well as columns and walls (vertical formwork).

The terms concrete formwork and concrete form carry the same meaning and are used interchangeably in this book.

Formwork is defined as a temporary structure whose purpose is to provide support and containment for fresh concrete until it can support itself. It moulds the concrete to the desired shape and size and controls its position and alignment.

Concrete forms are engineered structures that are required to support loads such as fresh concrete, construction materials, equipment, workers, various impacts, and sometimes wind. The forums must support all the applied loads without collapse or excessive deflection.

Use Full Article For You

- Causes of Failure of Foundation

- Best Concrete Bonding Agent

- Dead Load Formula

- Hemp Building Blocks

- Hempcrete Vs Concrete Cost

- Skeleton Frame

- Queen Mattress Size in Feet

- Types of Construction Cranes

- How to Determine Zero Force Members

- Shower Floor Cement

- How Many Cubic Yards in a Bag of Concrete

- What Is a Shovel

- How Long Does Mortar Take to Dry

- Definition of a Flight of Stairs

- What Is the Contour Interval of This Map?

- Plywood Tensile Strength

- Upstand Beam

- Inverted Arches

What Is Shuttering?

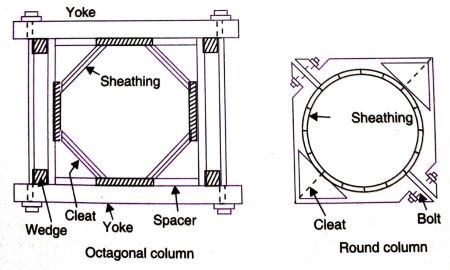

Vertical formwork is known as shuttering. Formwork for columns, retaining walls, footings are known as shuttering.

It is a part of formwork, which is quite popular now a days & constructed on sites by using Steel & plywood. formwork that supports vertical arrangement is known as shuttering.

It acts as moulds for pouring concretes, which supports the surface vertically during the construction process for instance column, beam, slab, wall sides & so on.

Moulds can be temporary or permanent wherein concrete or similar material is poured & formed. During shuttering, it is advisable to use waterproof & good quality plywood. In concrete construction methodology, the falsework supports the shuttering moulds.

Shuttering work is a vertical temporary arrangement that is arranged to bring concrete in the desired shape.

Also, read:Mivan Shuttering | Merit & Demerit Mivan Technology | Mivan Formwork Assembly Process

Types of Shuttering

- Wood Shuttering.

- Steel Shuttering.

- Aluminum Shuttering.

- Glass-Reinforced Shuttering.

What Is Centering?

Centering is a part of formwork. It is used to support horizontal members like slabs. Formwork for slabs and floor beams is known as centring.

Formwork that supports the horizontal surface such as beam, slab bottoms is call centring. It is the specialized formwork used in the construction of arches, shells space structure where the entire false-work is (struck or de-centred) as a unit to avoid introducing injurious stress in any part of a structure.

Types of Centering

- Wood Centering.

- Steel Centering.

- Aluminum Centering.

- Glass-Reinforced Centering.

Also, read: Test for Compressive Strength of Brick | Water Absorption | Dimensions Test

What Is Staging?

Staging is a temporary member which is used to support formwork, after completion of columns up to roof beam bottom construction of roof slab is stats.

The first stage is staging. Staging is noting but the erection of staging forms on which shuttering of roof slab or beam will rest.

Staging can be made of different type of materials starting wooden to metal parts, which hold is shuttering. Staging should be stable and firm to hold the load of the slab.

It should be firm enough so that during concreting it should properly hold the concrete & shuttering so that shuttering does not bulge of settle.

Also, read: Difference Between One Way Slab and Two Way Slab | What is Slab

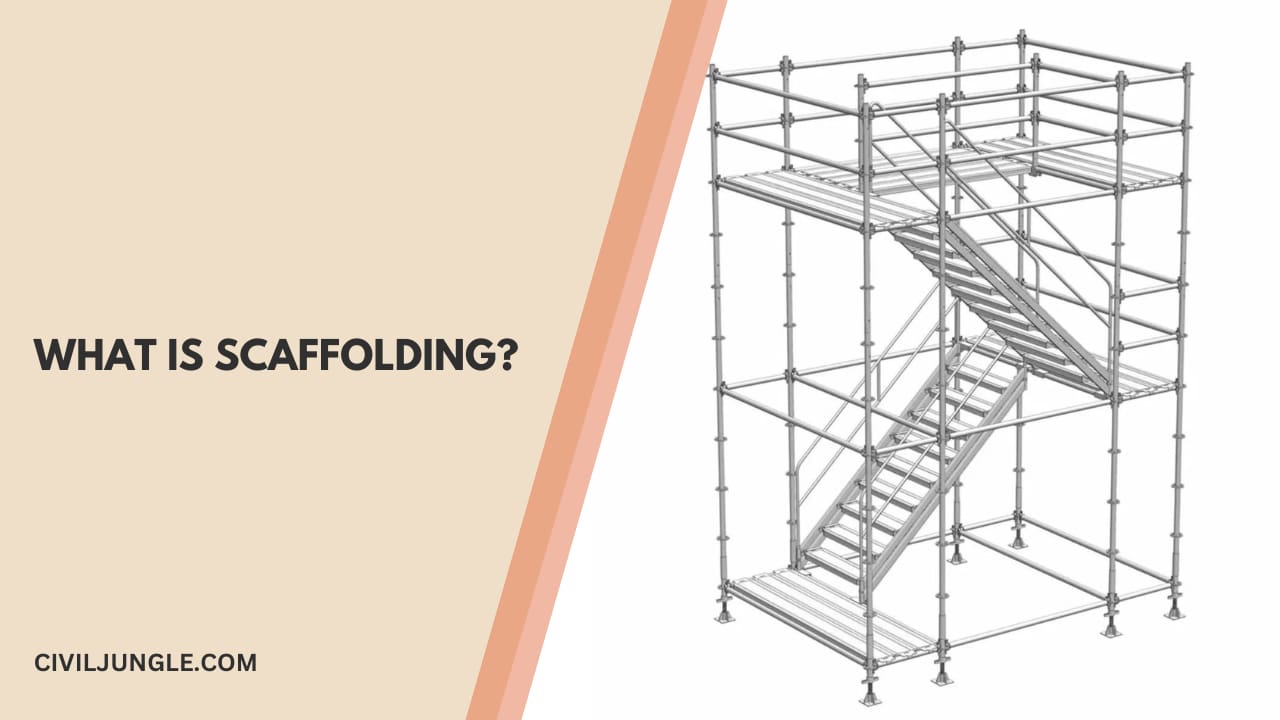

What Is Scaffolding?

Scaffolding is a temporary platform used to lift, support, and supply materials during a construction process for the repair or cleaning of a structure.

It is installed before construction or maintenance work begins. Therefore, whatever the size of a building, scaffolding will always be necessary.

This is done to ensure the safety of workers while the building is being maintained or constructed. In addition, it also provides some degree of support for a standing structure during the construction phase.

Scaffolding is made of wood or steel. It must be stable and strong to support workers and other construction materials placed on it.

Types of Scaffolding

- Single Scaffolding.

- Double Scaffolding.

- Cantilever Scaffolding.

- Suspended Scaffolding.

- Trestle Scaffolding.

- Steel Scaffolding.

- Patented Scaffolding.

- Wooden Gantries Scaffolding.

Shuttering Work

Shuttering is a part of formwork. It is a vertical temporary structure that is used to bring concrete in the desired shape. Or Vertical formwork is known as shuttering. Formwork for columns, retaining walls, footings are known as shuttering.

Centering Work

Centring, centre, centering, or center is a type of formwork: the temporary structure upon which the stones of an arch or vault are laid during construction. Until the keystone is inserted an arch has no strength and needs the centring to keep the voussoirs in their correct relative positions.

Difference Between Centering and Shuttering

Vertical formwork is known as shuttering. Formwork for columns, retaining walls, footings are known as shuttering. Centering is a part of formwork. Formwork for slabs and floor beams is known as centering.

Types of Formwork Materials for Construction

Types of Formwork Used in Construction

- Timber Formwork.

- Plywood Formwork.

- Metallic Formwork.

- Plastic Formwork.

- Fabric Formwork.

- Stay-in Place Formwork.

- Permanent Insulated Formwork.

Advantages of Using Shuttering in Building Construction

Shuttering Plywood can withstand intensive heavy-duty uses, resistant to moisture and extreme weather conditions. It is ideal for concrete purposes and other construction activities like repair and maintenance of buildings, bridges, roofing, cooling towers, among others.

How to Set Up Staging for Construction Projects?

Setting up a staging area for construction projects involves careful planning and organization. Here are some steps to help you establish an effective staging area:

- Evaluate the project site: Assess the available space on your construction site and identify the most suitable location for the staging area. Consider factors such as accessibility, proximity to the construction site, and any potential impact on neighboring properties.

- Determine staging area requirements: Understand the specific needs of your construction project to determine the requirements for the staging area. This may include space for storing materials, equipment, and temporary structures like trailers or portable offices.

- Obtain necessary permits and approvals: Check with local authorities and obtain any required permits or approvals for establishing a staging area. Compliance with zoning regulations and environmental restrictions is crucial.

Choosing the Right Scaffolding for Safety and Efficiency

Here are some factors to consider when selecting the appropriate type of scaffolding for your project:

- Height of the Project.

- Weight of the Load.

- Accessibility of the Site.

- Duration of the Project.

- Project Requirements.

- Nature of the Work.

- Ground Conditions.

- Building Regulations.

Benefits of Using Steel Shuttering in Construction Projects

Steel Formwork: Why Use It and What Are Its Main Advantages?

- Long-Term, Durable Solution. Steel formwork is the perfect long-term solution for a concrete construction job.

- Save Money.

- Extremely Strong.

- Great Versatility.

- Clean Concrete Finish.

- Non-Porous and Non-Absorbent.

Staging in Construction

Staging is dividing a construction area into two or more areas to minimize the area of soil that will be exposed at any given time.

Shuttering and Centering

Centering and shuttering are both formworks. Centering term is used when the formwork is horizontal like slab, floor beam, etc. Shuttering term is used when the formwork is vertical as in column, footing, retaining wall, etc. Steel and timber planks are commonly used materials for centering and shuttering.

What Is Centering in Construction?

Centering is essential for creating the desired shape and supporting the weight of the construction materials until they are set and hardened. It provides stability and ensures that the structure maintains its shape during the construction process. Centering is commonly used in the construction of bridges, tunnels, domes, and other structures that involve curved or arched elements.

What Is Shuttering?

Shuttering, also known as formwork, refers to the temporary structure or mold that is used to shape and support freshly poured concrete or other construction materials until they set and harden. It provides the desired form, containment, and support during the construction process.

What Is Centering and Shuttering in Construction?

Centering is used to support horizontal members. Hence, formwork for floor beams and slabs is known as centering. Shuttering is used to support vertical members. Hence, formwork for columns, footings, or retaining walls is known as shuttering.

What Is Formwork in Concrete?

formwork, Mold used to form concrete into structural shapes (beams, columns, slabs, shells) for building. Formwork can be of timber, steel, plastic, or fiberglass.

What Is Concrete Formwork?

Formwork molds the concrete to the desired size and shape, and controls its position and alignment. It is a temporary structure that supports its own weight and the freshly placed concrete, as well as construction live loads including materials, equipment, and workers.

What Is Concrete Shuttering?

Shuttering or formwork is the process of giving support and stability to the concrete before it becomes solid. The shuttering is commonly made using wood and steel. The right way to do shuttering is mentioned below.

Like this post? Share it with your friends!

Suggested Read –

- Road Development Plans in India

- What Is Scaffolding | Types of Scaffolding

- What Is Dry Pack Mortar | Advantages of Dry Pack Mortar | Disadvantages of Dry Pack Mortar

- Difference Between Whole Circle Bearing and Quadrantal Bearing | What Is WCB | What Is QB

- What Is Injection Grouting | Types of Injection Grouting | Different Types of Grouting Materials

- What Is Hempcrete | Hempcrete Blocks | Advantages & Disadvantages of Hempcrete Blocks | Applications of Hempcrete

- What Is Hard Hat | Hard Hat Colour Definition | Different Hard Hat Colour Codes | Types of Safety Helmets | Classification of Hard Hats

Originally posted 2023-06-22 16:58:53.

Leave a Reply