What Is a Concrete Surface Retarder?

Important Point

Surface retarders, also know surface“deactivators,” are applied to fresh concrete to chemically delay the set of the surface mortar. Unlike concrete set retarders, they allow the rest of the concrete to cure normally, without affecting the setting rate or strength gain.

Because surface retarders work their magic by stopping the hydration process down to a controlled depth, the underlying concrete will harden properly while allowing easy removal of this surface paste later.

Whenever you’re ready to expose the aggregate by hosing or high-pressure washing, the depth of aggregate reveal is more uniform with minimal pop-outs.

Also, read: Must-Have Knowledge for Civil Engineers | Civil Basic Knowledge

When Do You Apply Surface Retarder?

The best time to apply surface retarder is after you have completed all finishing operations and the bleed water has dissipated.

Do not seal the concrete first or apply curing compounds, which might prevent the retarder from doing its job.

Apply surface retarder evenly over the surface using a low-pressure sprayer or roller. Many surface retarders are designed to form a film over the surface which acts as a temporary curing agent and protects the concrete from mild wind and rain.

But if extreme wind or rain is expected, you need to protect the surface with plastic sheeting.

Types of Retarders

Retarders are divided into 2 categories depending on the nature of the retarders, they are

1. Organic Retarders

- Phosphonates

- Sugars

- Lignosulphonates

- Hydroxycarboxylic acids and their salts

2. Inorganic or Chemical Retarders

- Salts of Pb, Zn, Cu, As, Sb

- Phosphonates

- Borates

Also, read: What Is Measurement Book | How to Write Measurement Book | Recording Measurement Book

Effects of Retarding Admixtures on Properties of Concrete

- Strength

- Bleeding

- Durability

- Slump Loss

- Workability and Rheological Values

- Heat of Hydration

- Air Entrainment

- Freeze-Thaw Cycles

- Volume Deformation

#1. Strength

- The initial compressive strength of concrete into that retarding admixtures are added is lower than the compressive strength of a similar concrete that wasn’t treated with retarding admixtures.

#2. Bleeding

- Since retarding admixtures delay the beginning of the setting process, retarded concretes are always more likely to bleed.

#3. Durability

- If concrete is correctly cured, retarded concrete needs to be just as durable as equivalent plain concrete.

#4. Slump Loss

- Retarding admixtures have been shown to be very effective in reducing slump loss and in this way increasing the initial workability.

#5. Workability and Rheological Values

- Retarding admixtures have a small effect on the workability of concrete. They could cause an increase of initial slump by 60-100mm.

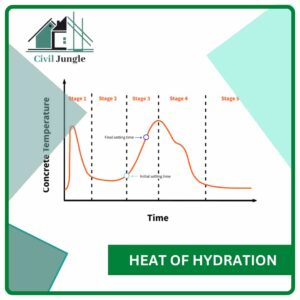

#6. Heat of Hydration

- Retarding admixtures don’t reduce the heat output of concrete however delay the rise of the peak temperatures by a time interval much like the one where the concrete was retarded.

#7. Air Entrainment

- Retarding admixtures do not normally entrain air but there are some kinds of retarders that do. Especially these based on hydroxycarboxylic acid can actually reduced air content.

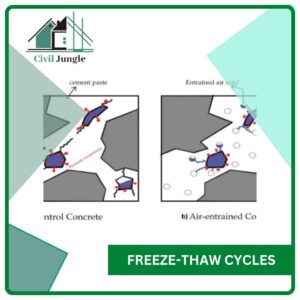

#8. Freeze-Thaw Cycles

- Air entraining admixtures are often utilized to improve the freeze-thaw resistance of concrete. After the water from the concrete starts freezing, the air cells function as microscopic expansion chambers to the freezing water.

#9. Volume Deformation

- Creep and drying shrinkage isn’t significantly affected by the inclusion of retarding admixtures but plastic shrinkage might be slightly increased.

Also, read: What Is Well Foundation | Component of Well Foundation

Advantages of Retarder in Concrete

Considered a boon for the construction Procedure, in the long run, concrete retarders Help with multiple advantages and a Few major advantages are being discussed below for your reference,

- Retarding admixtures extend the setting time of concrete and maintain the workability and cohesion for an extended period of time.

- From the large construction projects, concrete retarder prevents cold joints formation in successive lifts and make concretely workable through concrete placing.

- With the usage of concrete retarders, you can compensate for the accelerating effect of high temperature towards the initial setting time and minimize risks of long-distance delivery in warm weather.

- The usage of retarding admixtures improves the permeability of concrete by delayed setting period and improved workability of concrete.

- Concrete retarders help to reduce segregation and bleeding in concrete where poor sand grading is unavoidable.

Also, read: What Is Crane | Different Types of Cranes

Disadvantages of Concrete Retarders

Everything has a slice of precautions or you may say disadvantages. The same stands true in the event of concrete retarders.

Laid below are a few common disadvantages that you ought to know about before using concrete retarders for your construction process.

- The concrete retarders may be employed with water-reducers however care needs to be taken while curing to avoid bleeding and cracks.

- The dosage of retarding admixtures must be within limits based upon its water-cement ratio, cement content, and amount of C3A from the cement.

- Use of gypsum as a retarding admixture for the purpose of retarding setting time is recommended when adequate control and inspection can be obtained, otherwise, the addition of excess amount can cause undesirable expansion and an indefinite delay in the setting of concrete.

- Concrete retarders could have variable action on different kinds of cement when used in different quantities.

Also, read: What Is Standard Proctor Test & his Detail | Procedure Standard Proctor Test

Uses of Concrete Retarders

Concrete retarders are abundantly used or applied in various construction settings; however, some most popular uses or applications are given over here,

- Retarding admixtures are most commonly used in hot weather concreting.

- Retarder Concrete sprayed to the surface of the formwork to prevent the hardening of this matrix in the interface of concrete and formwork, whereas the rest of the concrete gets.

- Retarders are utilized for large or massive construction work hardened.

- Retarding admixtures are used in grouting oil wells.

Retarders in Concrete

Retarding admixtures, which slow the setting rate of concrete, are used to counteract the accelerating effect of hot weather on concrete setting. Retarders keep concrete workable during placement and delay the initial set of concrete. Most retarders also function as water reducers and may entrain some air in concrete.

What Is Retarder in Concrete?

Retarding admixtures are used to slow the rate of setting of concrete. By slowing the initial setting time, the concrete mixture can stay in its fresh mix state longer before it gets to its hardened form. Use of retarders is beneficial for: Complex concrete placement or grouting.

Types of Retarders in Concrete

There are two kinds of retarders, defined as Type B (Retarding Admixtures) and Type D (Water Reducing and Retarding Admixtures). The main difference between these two is the water-reducing characteristic in Type D that gives higher compressive strengths by lowering w/cm ratio.

Retarding Admixture Setting Time of Concrete

Contact the admixture manufacturer for advice on the likely retardation time at the actual dosage used. Unless an extreme overdose was used, most concrete will set and gain strength normally within 3–5 days. Beyond 5 days, the potential for the concrete not to gain full strength increases significantly.

Disadvantages of Concrete Retarders

The use of retarding admixture has the main drawback of the possibility of rapid stiffening, where rapid slump loss will result in difficulty of concrete placement, consolidation, and finishing.

Retarder Concrete

Concrete retarders are the mixture that slows down the chemical process of hydration so that the concrete remains plastic and workable for a long time, retarders are used to overcome the accelerating effect of high temperatures on establishing the properties of concrete in hot climates.

Retarder in Cement

Set retarders are used to prevent a premature hardening of the cement slurry before it reaches the area to be cemented. Set retarders prolong the setting time of the cement to allow time for the cement to be pumped into place [7]. Common retarders used include lignins and sugars, as well as some metal oxides and acids.

Retarder for Concrete

Retarders for concrete are used to delay the initial setting time of the concrete upto an hour. They are generally used in the hot weather condition to counter the rapid hardening due to high temperature, thus allowing the time for mixing, transporting and placing. Retarders also acts as water reducers.

Cement Retarder

A cement retarder is a chemical additive that is added to cement during the mixing process to slow down the rate of setting or hardening. This helps to increase the working time of the cement, making it easier to use in construction projects.

Use of Retarders in Concrete

Retarders keep concrete workable during placement and delay the initial set of concrete. Most retarders also function as water reducers and may entrain some air in concrete.

Concrete Retarder Admixture

Retarding admixtures, which slow the setting rate of concrete, are used to counteract the accelerating effect of hot weather on concrete setting. High temperatures often cause an increased rate of hardening which makes placing and finishing difficult.

Retarder Used in Cement

The most commonly known concrete retarder is calcium sulphate – gypsum. Sugar is also one of the most common and effective retarding admixture which is used for delaying the setting time of concrete without detrimental effect on the ultimate strength of concrete itself.

Retarder Cement

Retarder cement is a type of cement that contains a chemical additive known as a retarder. This additive is used to slow down the setting time of the cement, which allows more time for placing and finishing the cement.

What Is Concrete Retarder?

Retarding admixtures are used to slow the rate of setting of concrete. By slowing the initial setting time, the concrete mixture can stay in its fresh mix state longer before it gets to its hardened form. Use of retarders is beneficial for: Complex concrete placement or grouting. Special architectural surface finish.

Concrete Retarder Types

Types of Retarders

- Organic Retarders. Lignosulphonates. Hydroxycarboxylic acids and their salts. Phosphonates. Sugars.

- Inorganic or Chemical Retarders. Phosphonates. Borates. Salts of Pb, Zn, Cu, As, Sb.

Like this post? Share it with your friends!

Suggested Read –

- What Is Concrete | 31 Different Types of Concrete

- What is Salt Concrete Finish | How to Create a Salt Finish

- Difference Between CPM and PERT | What Is CPM & PERT

- Difference Between One Way Slab and Two Way Slab | What is Slab

- What Is Sand Blasting | Concrete Sand-blasting Equipment | Key Benefits

- What Is Isometric Projection | Principle of Isometric Projections | Isometric Scale

- What Is Structural Settlement | Causes For Structural Settlement | What Is Soil Settlement & Foundation Structural Settlement

Originally posted 2023-05-02 17:05:44.

Leave a Reply