Fineness Modulus of Fine Aggregate:

Important Point

The sand fineness module (fine aggregate) is an index number describing the mean size of sand particles. By doing sieve analysis with normal sieves, it is measured.

The accumulated percentage kept on each sieve is applied and the sum of the fine aggregate is subdivided by 100. To find the fine aggregate fineness modulus, we require 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, and 0.15mm sieve sizes.

The fineness modulus of the finer aggregate is greater than the coarse aggregate fineness module.

Fineness Modulus of Coarse Aggregate

The fineness modulus of coarse aggregates is the index number of the total particle size of the coarse aggregate. By doing sieve analysis with normal sieves, it is measured. The accumulated percentage retained on each sieve is applied and the coarse aggregate valuation is given by subdividing it by 100.

The fineness module is larger than the fine aggregate, thus the fineness module of the coarse aggregate is greater than the fine aggregate.

We require sieve sizes of 75mm, 37.5mm, 19mm, 9.5mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm and 0.15mm and determine the coarse aggregate fineness modulus.

The Fineness module is the number that is identified when we calculate the particle size from the lower order standard sieves to the higher-order sieve. So, we require all sizes of sieves in the coarse aggregate measurement.

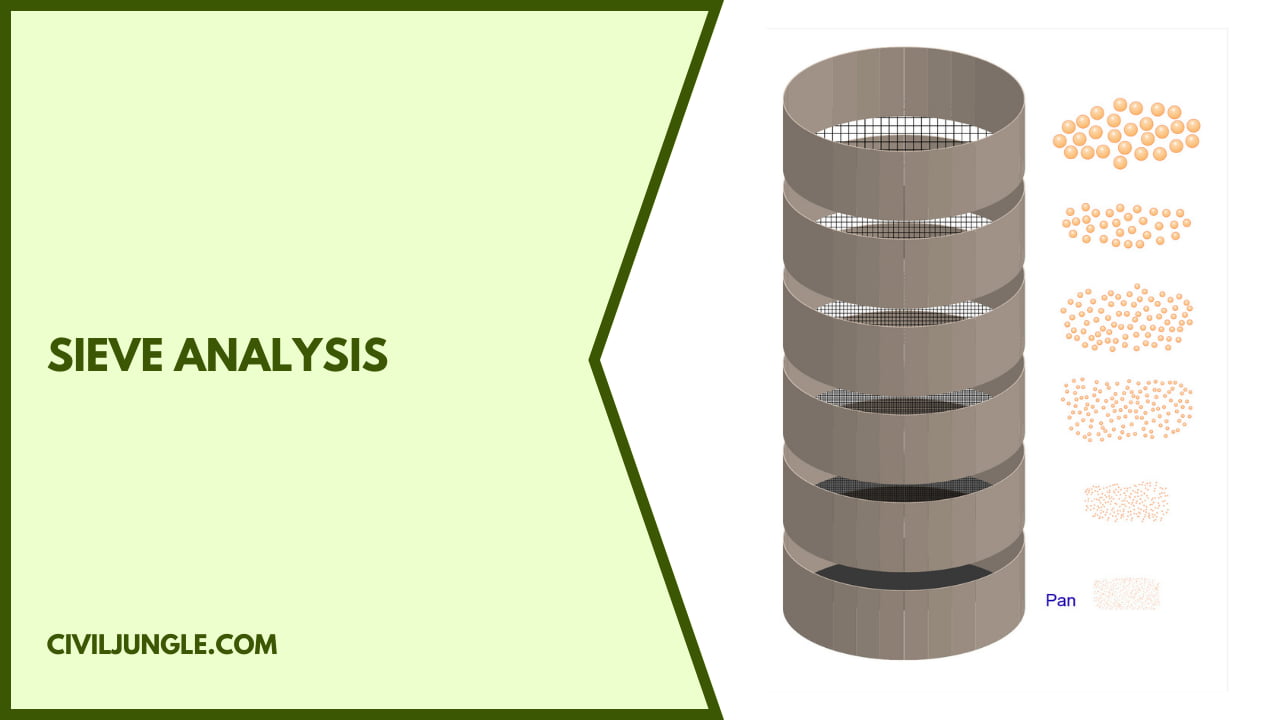

Sieve Analysis

Analysis of the sieve helps to determine the distribution of the particle size of the coarse and fine aggregates. This is achieved by sieving the aggregates according to IS: 2386 (Part I)-1963.

As standardized by the IS code, we use various sieves in this and then pass aggregates through them and thus collect various-sized particles leftover various sieves.

The equipment used are-

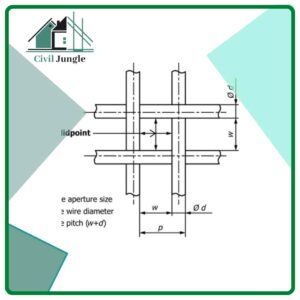

#1. 80mm, 63mm, 50mm, 40mm, 31.5mm, 25mm, 20mm, 16mm, 12.5mm, 10mm, 6.3mm, 4.75mm, 3.35mm, 2.36mm, 1.18mm, 600μm, 300μm, 150μm and 75μm.

#2. Balance or scale with precision to measure 0.1% of the test sample’s weight.

The available sample weight should not be less than the weight given below:

Procedure to Determine the Distribution of Aggregates by Particle Size.

- The test sample is dried and measured at a steady weight at a temperature of 110 + 50

- A set of IS sieves is used to sieve the sample.

- The substance on each sieve is weighed upon completion of the sieve.

- As a proportion of the overall sample weight, the average weight moving through each sieve is measured.

- The fineness module is obtained by applying to each sieve the total percentage of aggregates maintained and by dividing the sum by 100.

Also, Read: What Is Specific Gravity Cement | Why We Calculate Specific Gravity Cement | Specific Gravity Test on Cement

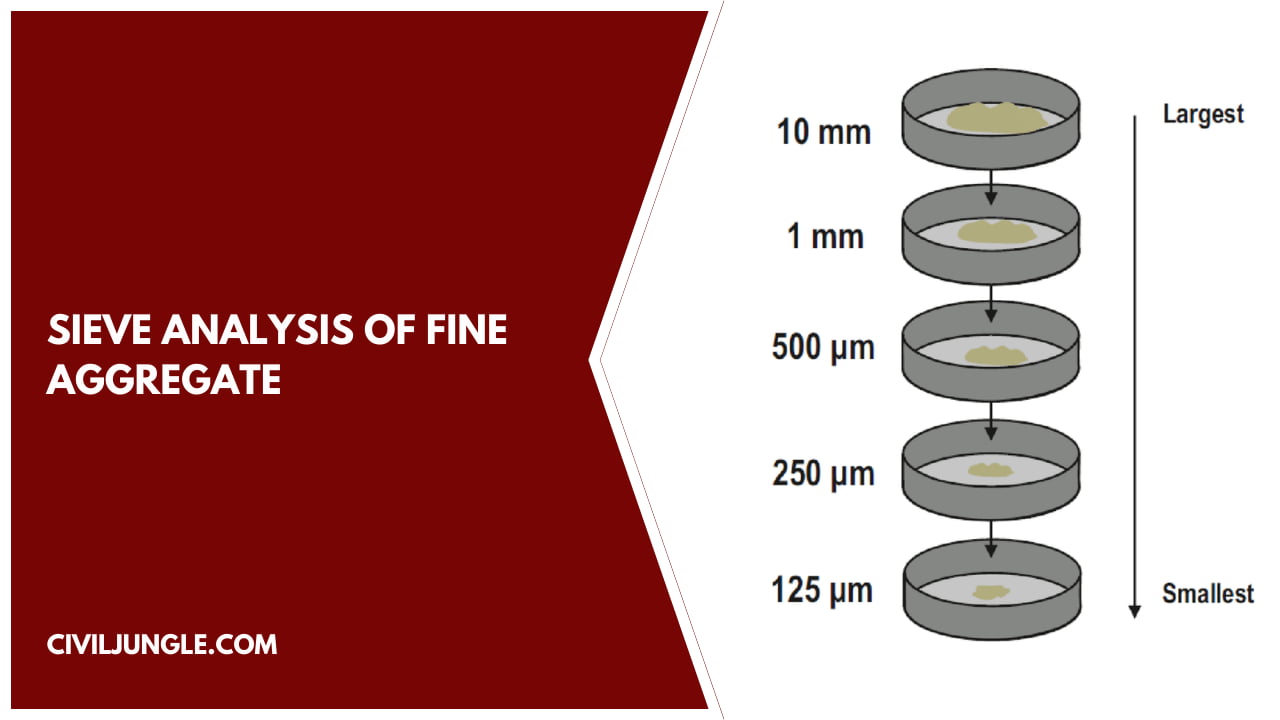

Sieve Analysis of Fine Aggregate:

One of the most relevant experiments conducted on-site is the Sieve analysis of Sand. Aggregates are neutral materials which are combined for mortar or concrete manufacture with binding materials such as cement or lime. It’s also found in mortar and asphalt as fillers.

The size of the aggregate ranges from several inches to the size of the smallest sand particle. In general, the aggregates occupy 60 to 75 percent of the concrete volume or 70 to 85 percent by weight and greatly affect the freshly mixed and hardened properties, mixture proportions, and economy of the concrete.

All IS 4.75 mm sieve pass aggregates and known as fine aggregates. In order to determine conformity with the design, quality control criteria, and verification parameters, all aggregate technicians use a sieve analysis (gradation test) to determine the gradation (particle size distribution, by size, within a given sample).

The sieve analysis is really useful for the monitoring and quality acceptance technique used in combination with other studies.

Gradation implies the distribution of the scale of the particles within the overall size range. On a graph, gradation can be classified as well-graded, uniform, or gap graded (sometimes referred to as skip graded), listed below.

- Well graded means the sizes are in nearly equal proportions across the whole range, although the largest and smallest particles would be very different.

- Uniform gradation means that the particles have a significant proportion of the same dimension. Gap graded or skip graded means that with a few particles of an intermediate scale, most particles are high in size or tiny in size.

- Targets: The whole sieve analysis technique is to determine the distribution of the particle size of the fine aggregates and to determine if it is appropriate for use in concrete mixing.

Equipment for Testing

#1. Sieves for IS 75 mm, 36 mm, 18 mm, 600 mic, 300 mic, 150 mic, 75 mic.

#2.Shovel and Skillet.

#3. Balance or scale with an accuracy representing 0.1 percent of the sample’s weight.

#4. Mechanical sieve shaker.

#5. Fine aggregates of 1000 grams.

Sieve Analysis Test Procedure-

Step 1. Dry the sample at a temperature of 110+ 50 C at a constant weight.

Step 2. Next the sieve and put the sample on the top sieve in order to reduce the scale of the opening from top to bottom.

Step 3. Shake the sieves for a suitable time, say 15 times or 28 minutes, by hand or by mechanical apparatus. A correct series (forward and backward motion, left and right motion, clockwise (CW) and counter-clockwise (CCW) motion and regular jolting) should be done by the manual process.

Step 4. Restricted the volume of material on a given sieve such that all objects have the ability to enter the opening of the sieve several times during the sieving process. For sieves with openings greater than 4.75 mm, the weight maintained on each sieve shall not exceed 6 kg/m2 (4 g/in2) of the sieving surface at the end of the sieving operation.

Step 5. In the case of sieves with apertures of 4.75 mm and wider, the weight in kg/m of the sieving surface must not exceed 2.5 of the product (sieve opening in mm). In no case shall the weight be so high as to cause the sieve cloth to be permanently deformed.

Step 6. Continue sieving for a reasonable amount of time and in such a way that no more than 1 percent of the residue on any particular sieve can move through the sieve after 1 minute of continuous hand sieving after completion.

Step 7. Place the fine aggregate sample in the top sieve, place the cap on top of the sieve stack, and agitate for 10 to 15 minutes by using the mechanical sieve shaker.

Step 8. Carefully extract the sieves one at a time and, with its retained aggregate, measure each sieve. Calculate the material mass stored on each sieve, deducting the resulting sieve’s weight. Determine the weight of each rise in size by measuring the nearest 0.1 percent of the overall initial dry sample weight on a scale or balance.

Step 9. The overall substance weight after sieving should be carefully checked with the original sample weight put on the sieves. If depending on the initial dry sample weight, the sum varies by more than 0.3 percent, the data can not be considered for approval purposes.

Also, Read: Non-Destructive Testing of Concrete | Type of Non-Destructive Testing Concrete

Calculation of Sieve Analysis Test

- Calculate passing ratios, cumulative percentage held, or percentages to the nearest 0.1 percent in separate scale fractions on the basis of the total weight of the original dry sample.

- Calculate the fineness modulus (FM) by applying to the sample the average amount of content that is coarser than any of the normal flowing sieves (Cumulative percentage retained) and by dividing the number by 100:150-m (No. 100), 300-m (No. 50), 600-m (No. 30), 1.18-mm (No. 16), 2.23-mm (No. 8), 4075-mm (3/8-in), 37.5-mm (1.5-in) and wider (3 in or 6 in). If any non-standard sieve is used, apply the total percent retention of this sieve during FM measurement to the next lower-sized standard sieve.

Also Read: Structural Frame Analysis

Report of Sieve Analysis Test

The following are included in the report:

- The absolute proportion of material moving through each sieve, or

- The overall proportion of material retained on each sieve or on each sieve

- Percentage of material between consecutive sieves maintained

- Report the fineness modulus to the nearest 0.01 as necessary.

Also, Read: Lab Test on Aggregates at Site

Sand Zone Classification:

| IS Sieve | Zone 1 | Zone 2 | Zone 3 | Zone 4 |

| 10 mm | 100 | 100 | 100 | 100 |

| 4.75 mm | 90 – 100 | 90 – 100 | 90 – 100 | 90 – 100 |

| 2.36 mm | 60 – 95 | 75 – 100 | 85 – 100 | 95 – 100 |

| 1.18 mm | 30 – 70 | 55 – 90 | 75 – 100 | 90 – 100 |

| 600 microns | 15 – 34 | 35 – 59 | 60 – 79 | 80 – 100 |

| 300 microns | 5 – 20 | 8 – 30 | 12 – 40 | 15 – 50 |

| 150 microns | 0 – 10 | 0 – 10 | 0 – 10 | 0 – 15 |

Table for Fine Aggregate:

| SIEVE NO. | SEIVE SIZE | SIEVE WITH MATERIAL | WEIGHT OF SIEVE | MATERIAL RETAINED | % MATERIAL RETAINED | CUMULATIVE % RETAINED | % FINER |

| TOTAL |

Table for Coarse Aggregate:

| SIEVE NO. | SEIVE SIZE | SIEVE WITH MATERIAL | WEIGHT OF SIEVE | MATERIAL RETAINED | % MATERIAL RETAINED | CUMULATIVE % RETAINED | % FINER |

| TOTAL |

Also, Read: Test for Compressive Strength of Brick | Water Absorption | Dimensions Test

What Is Fineness Modulus?

The Fineness Modulus (FM) is an empirical figure obtained by adding the total percentage of the sample of an aggregate retained on each of a specified series of sieves, and dividing the sum by 100.

Sieve Analysis Procedure

The fineness modulus of fine aggregate varies from 2.0 to 3.5mm.

Values of Fineness Modulus of Sand.

| Type of Sand | Fineness Modulus Range |

|---|---|

| Fine sand | 2.2 mm – 2.6mm |

| Medium sand | 2.6 mm – 2.9 mm |

| Coarse sand | 2.9 mm – 3.2 mm |

Fineness Modulus of Fine Aggregate

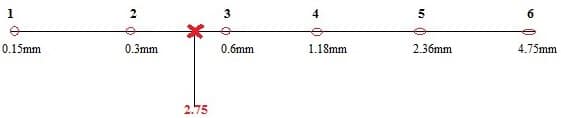

Fineness modulus of fine aggregate is 2.75. It means the average value of aggregate is in between the 2nd sieve and 3rd sieve. It means the average aggregate size is in between 0.3mm to 0.6mm as shown in below figure.

Fineness Modulus of Coarse Aggregate

The same value of fineness modulus may therefore be obtained from several different particle size distributions. In general, however, a smaller value indicates a finer aggregate. Fine aggregates range from an FM of 2.00 to 4.00, and coarse aggregates smaller than 38.1 mm range from 6.75 to 8.00.

Sieve Analysis of Sand

Fineness modulus of sand (fine aggregate) is an index number which represents the mean size of the particles in sand. It is calculated by performing sieve analysis with standard sieves. The cumulative percentage retained on each sieve is added and subtracted by 100 gives the value of fineness modulus.

Sieve Analysis Test Procedure

- Step 1: Take a representative oven-dried sample that weighs approximately 500g.

- Step 2: If particles are lumped or conglomerated, crush the lumps but not the particles using the pestle and mortar.

- Step 3: Determine the mass of the sample accurately – Weight (g).

- Step 4: Prepare a stack of test sieves.

- Step 5: Weigh all the sieves and the pan separately.

- Step 6: Pour the samples from step 3 into the top of the stack of sieves and put the lid on, place the stack in the sieve shaker and fix the clamps, adjust the timer to between 10 and 15 minutes, and switch on the shaker.

- Step 7: Stop the sieve shaker and measure the mass of each sieve and retained soil/material.

Sand Zone Classification

It divides the sand in four zones i.e. from Zone I to Zone IV. Zone I–Sand being very coarse and Zone 4 sand is very fine. It is generally recommended by code to use sands of zones I to Zone III for Structural concrete works.

What Is Fineness Modulus of Sand?

The Fineness Modulus of Sand is an index number that indicates the mean size of the sand particles. It is calculated by performing the sieve analysis test with standard IS sieves. The fineness modulus of sand ranges from 2.2 to 3.2. To find the fineness modulus of fine aggregate required IS sieve are sizes of 4.75mm.

How to Calculate Fineness Modulus?

The Fineness Modulus (FM) is an empirical figure obtained by adding the total percentage of the sample of an aggregate retained on each of a specified series of sieves, and dividing the sum by 100.

Fineness Modulus of Coarse Aggregate

Fineness modulus of coarse aggregates represents the average size of the particles in the coarse aggregate by an index number. It is calculated by performing sieve analysis with standard sieves. The cumulative percentage retained on each sieve is added and subtracted by 100 gives the value of fine aggregate.

What Is the Typical Range of Fineness Modulus Values for Fine Aggregates?

Fine aggregates range from an FM of 2.00 to 4.00, and coarse aggregates smaller than 38.1 mm range from 6.75 to 8.00.

What Is Fineness Modulus and Its Importance?

The significance of fineness modulus (FM) is in specifying the proportions of fine and coarse aggregates when designing concrete mixes. The higher the value of FM, the coarser the aggregate. Generally, a lower FM results in more paste, making the concrete easier to finish.

How Do You Calculate Fineness Modulus of Sand?

To calculate the fineness modulus of sand, the sum of the cumulative percentages retained on the following sieves are divided by 100: 150μm (No. 100), 300μm (No. 50), 600-μm (No. 30), 1.18mm (No. 16), 2.36mm (No. 8), and 4.75mm (No. 4) for fine aggregates.

What Is the Fineness Modulus of Portland Cement?

AASTHO Designation: M6-93- “Standard Specification for Fine Aggregate For Portland Cement Concrete”- It indicates that the fineness modulus of sand will not be less than 2.3 and nor more than 3.1.

What Is the Effect of Fineness Modulus on Hydration?

The fineness of cement affects hydration rate, and in turn, the strength. Increasing fineness causes an increased rate of hydration, high strength, and high heat generation. Bleeding can be reduced by increasing fineness.

Why Do We Calculate Fineness Modulus?

The significance of fineness modulus (FM) is in specifying the proportions of fine and coarse aggregates when designing concrete mixes. The higher the value of FM, the coarser the aggregate. Generally, a lower FM results in more paste, making the concrete easier to finish.

What Does a High Fineness Modulus Mean?

The significance of fineness modulus (FM) is in specifying the proportions of fine and coarse aggregates when designing concrete mixes. The higher the value of FM, the coarser the aggregate. Generally, a lower FM results in more paste, making the concrete easier to finish.

What Is the Use of Fineness Modulus of Fine Aggregate?

The significance of fineness modulus (FM) is in specifying the proportions of fine and coarse aggregates when designing concrete mixes. The higher the value of FM, the coarser the aggregate. Generally, a lower FM results in more paste, making the concrete easier to finish.

Why Is Knowing Fineness Modulus Necessary for Sand?

Fineness Modulus of Sand affects Compressive and flexural strength of Concrete. Sand, with higher FM, results in higher strength of concrete. It is evident by cost benefit ratio that overall concrete mix is becoming economical if we use sand with higher FM.

How Do You Interpret Fineness Modulus?

The significance of fineness modulus (FM) is in specifying the proportions of fine and coarse aggregates when designing concrete mixes. The higher the value of FM, the coarser the aggregate. Generally, a lower FM results in more paste, making the concrete easier to finish.

What Is Meant by Fineness Modulus?

In a nutshell, fineness modulus describes the gradation curve as well as the texture and uniformity of the material. A lower FM factor means that the aggregate particles in that sample are finer on average.

What Is the Fineness Modulus of Cement?

The Fineness modulus of cement is an empirical figure obtained by adding the total percentage of the sample of an aggregate retained on each of a specified series of sieves, and dividing the sum by 100. The proportion of cement of which the grain sizes are larger than the specified mesh size is thus determined.

What Is the Fineness Modulus Used for?

Fineness modulus offers a way to quantify the average size of the aggregate particles in the concrete mix. The size of the particles, in turn, will greatly affect how easily the concrete pours and spreads, as well as its strength and durability once cured.

What Is the FM of Sand?

FM of Sand– 2.2 to 3.2. The Fineness Modulus of Sand is an index number that indicates the mean size of the sand particles. It is calculated by performing the sieve analysis test with standard IS sieves. The fineness modulus of sand ranges from 2.2 to 3.2.

Which Zone Sand Is the Finest Sand?

Zone I–Sand being very coarse and Zone 4 sand is very fine. It is generally recommended by code to use sands of zones I to Zone III for Structural concrete works.

What Is Fineness Modulus Used For?

Fineness modulus offers a way to quantify the average size of the aggregate particles in the concrete mix. The size of the particles, in turn, will greatly affect how easily the concrete pours and spreads, as well as its strength and durability once cured.

What Is the Range of Fineness Modulus?

Fine aggregates range from an FM of 2.00 to 4.00, and coarse aggregates smaller than 38.1 mm range from 6.75 to 8.00. Combinations of fine and coarse aggregates have intermediate values.

Fineness Modulus of Sand

The Fineness Modulus (FM) of fine aggregates (sand) is an empirical figure obtained by adding the total percentage of the sample of a sand retained on each of a specified series of sieves, and dividing the sum by 100.

Fineness Modulus of Sand as Per Is Code

The Fineness modulus of sand is 2.76. It means the mean size of particle in sand is between the 2nd and 3rd sieve.

Sieve Analysis of Coarse Aggregate

The sieve analysis of coarse aggregate test indicates the size distribution of coarse aggregate particles in a given coarse aggregate sample. The fineness modulus is the indication of the mean size of the particles. The fineness modulus is used to grade the given aggregate.

Fineness Modulus of Sand Limit

Values of Fineness Modulus of Sand

Fineness modulus of fine aggregate varies from 2.0 to 3.5mm. Fine aggregate having fineness modulus more than 3.2 should not considered as fine aggregate.

Zone of Sand

Generally, manufactured sand is classified as Zone I, Zone II, Zone III and Zone IV (i.e. coarser to finer). There is sieve designation for each zone. Gradation is made in accord with the usage of the sand.

Fine Modulus of Sand

The term “fine modulus of sand” typically refers to the fineness or grading of sand particles. It is a measure of the particle size distribution of the sand and is used to determine the suitability of the sand for various applications, such as construction, concrete production, and soil stabilization.

Like this post? Share it with your friends!

Suggested Read –

- Coarse Soil

- Structure of Sand

- Coarse and Fine Aggregate

- What Is Dressing of Stone | Types of Dressing of Stone

- Floating Slab Vs Monolithic Slab | What Is Monolithic Slab | What Is Floating Slab

- RCCFull Form | What Is RCC | Advantages & Disadvantages of Reinforced Cement Concrete | Properties of RCC | What Does RCC Stands for

- What Is a Cavity Wall | How to Build a Cavity Wall | Cavity Wall Detail | Cavity Wall Thickness | Cavity Wall Insulation Pros and Cons | Brick Cavity Wall

- What Is Oblique Drawing | Oblique Drawing Examples | What Is Oblique View | Oblique Projection | Oblique Shape | Cabinet Oblique | What Is Cavalier Drawing

- Which of the Following Is a Way That Slopes Fail | Types of Slope Failure | Geotechnical Failures | Types of Slopes in Geography | Causes of Slope Failure | Slope Stability

- What Is Pier and Beam Foundation | Advantages & Disadvantage of Pier and Beam Foundations | Pier and Beam Foundation Design | How to Build a Post and Pier Foundation

Originally posted 2023-07-06 16:06:48.

Leave a Reply