What is CBR Test?

Important Point

CBR Test Full Name is California Bearing Ratio (CBR)

In the year 1930, this test was developed by the California Division of Highways around 1930 and was consequently accepted by several states, nations, the U.S. federal agencies, and worldwide.

As a result, in the US, most agency and commercial geotechnical laboratories are set to perform CBR tests.

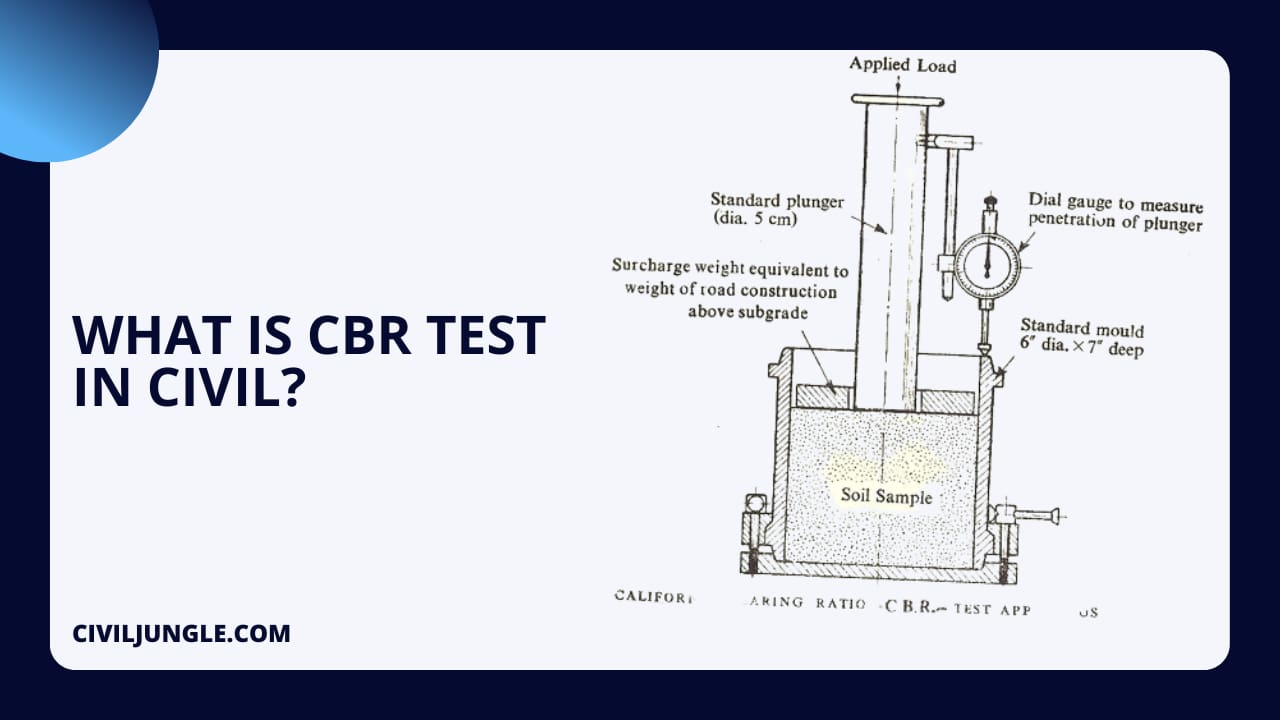

The CBR(California bearing ratio) test is one kind of strength testing system that allows to compares of the bearing capacity of a standard graded cursed stone (mainly it should have its maximum of 100% of CBR value). The CBR(California Bearing Ratio) test is a determination of the resistance of a material to penetration of standard plunger in controlled density and moisture conditions.

It is mainly projected for, examine the strength of cohesive materials having the largest particle sizes lower than 19 mm (0.75 inches).

The intent of this test is the evaluation of the CBR (California Bearing Ratio) value of the subgrade soil.

The evaluation of the bearing strength of subgrade soil and bases is to fulfill the criteria of the road and pavement construction by using this testing method.

This is the main objective of the CBR test.

California Bearing Ration test is the proportion articulated infraction of force per unit area necessary for penetrating a soil mass with a standard circular plunger of 25 mm radius at the rate of 1.25 mm/min to that required for related penetration in a standard material.

The proportion is generally found out for penetration of 2.5 and 5 mm.

If the ratio at 5 mm is consistently upper than that at 2.5 mm, the ratio at 5 mm is used. This method covers the laboratory technique for finding out the C.B.R. of compacted soil specimens in a wet state.

Also, read: What Is Soundness of Cement Test

How to CBR Test Complete?

CBR Test Machine

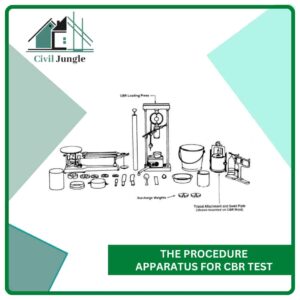

Apparatus Required for CBR Test

Loading Machine for CBR Test :

California Bearing Ratio Test apparatus includes a loading machine with a minimum capacity of 5000 kg and set with a mobile head or base, which enables Plunger of 50 mm diameter, and 1.25 mm per minute is the rate of penetration to penetrate the specimen.

Mould in this test with Stay Rod, Base Plate, and Wing Nut Cylindrical mold:

- Inside diameter of 150mm and height of 175mm with a separable perforated base plate of 10mm thickness and 235mm diameter.

- It has a net capacity of 2250 ml, meeting the requirements of IS-9669:1980.

- There is one detachable extension collar with 60 mm height, Spacer Disc with 148 mm diameter, and height of 47.7 mm along with the handle.

- Furthermore, several slotted weights weighing 2.5 kg each weight and single annular metal weight and, 147 mm in diameter, with a hole in the center of 53 mm in diameter.

- In this test, the height of the drop is 450 mm for compaction Rammer, and its weight is 4.89 kg.

Also, read: Lab Test on Aggregates at Site

Step up Apparatus for CBR Test

- Lubricating oil is applied in the internal surface of the mould to make it frictionless removals of soil.

- Start compacting the mixed soil in the mould by helping bit heavy compaction. i.e.By using 4.89 kg rammer, compact the soil in 5 layers with 55 blows to each segment.

- Afterward, remove the extension collar and level and trim the compacted soil carefully at the topmost level of mould or leveling of the top surface.

- In case if there are any voids developed on the top surface of the compacted soil after removal of the coarse material, all voids refilled by using smaller particles of soil material.

- The next step is to measure the weight of the compacted soil specimen and mass of the mould, after removing the perforated base plate, Spacer disc, and filter paper.

- Put this filter paper on the base plate and reverse the mould and remove the compacted soil. Hence this soil came in contact with the filter paper.

- Set a filter paper above the specimen, on the other hand, place a perforated plate on top of the compacted soil specimen in the mould.

- Lay annular weights to generate a surcharge equivalent to the weight of base material and pavement, to the nearby 2.5 kg.

- Now, submerge the mould assembly and weights into a tank of water and saturate it up to 96 hours. Set the stand for expansion measuring device on the edge of the mould, record preliminary dial gauge reading.

- The second step is to Note down the readings every day adjacent to the time of reading. Make sure that the water level shall remain constant to maintained in the tank right through the period.

- Final step or at the end of the soaking period, parallel note down the last reading of the dial gauge and get the mould out from the water tank.

- Take out the extra water collected in the mould and allocate the specimen to draw off for 15 minutes. At last, Remove the perforated plate and the filter paper from the top layer, evaluate the soaked soil sample and record the weight.

Also, test: What Is the Penetration Test | What Is the SPT Test | Procedure | Efficiency | Advantages and Disadvantages

The Procedure Apparatus for CBR Test

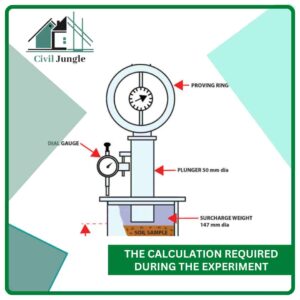

- Firstly, set the mould assembly with a test specimen on the lower plate of the penetration testing machine.

- For avoiding disruption of soil into the hole of the extra weights, 2.5 kg annular pressure shall be sited. Before setting out surcharge weight placed on the soil surface, first to set the penetration plunger.

- The penetration piston is set at the middle of the specimen with the nominal possible load; however, in some cases, over 4 kg, thus full contact of the piston on the pattern, is established.

- Set the weight on it, so deformation gauges are to be read zero, by applying the load on the piston hence the penetration rate is nearly 1.25 mm/min.note down all load readings at penetrations of 0.5, 1.0, 1.5, 2.0, 2.5, 4.0, 5.0, 7.5, 10 and 12.5 mm.

- Pull up the plunger and separate the mould from the loading equipment.

- Afterward, Take out 20 to 50 g of soil from the top 30 mm layer and find out the moisture content.

Also, test: What Is Workability of Concrete | Factors Affecting Workability | Test |Errors

The Calculation Required During the Experiment:

Let start with the initial portion of the curve is concave to upwards directions.

To correct by sketching a tangent on the curve at the point of the maximum slope and move the origin. After that, Find out and note down the accurate load reading corresponding to each penetration.

Formula of calculation

C.B.R. = (PT/PS) X 100

where,

PS = Standard load for the same penetration taken from the table above, and PT = Corrected test load corresponding to the selected penetration from the load penetration curve.

| Penetration(mm) | Standard Load(kg) |

Unit Standard Load(kg/cm2)

|

| 2.5 | 1370 | 70 |

| 5 | 2055 | 105 |

| 7.5 | 2630 | 134 |

| 10 | 3180 | 162 |

| 12.5 | 3600 | 183 |

Standard Load Values for CBR Test

- C.B.R. value at 2.5 mm penetration = 3.

- C.B.R. value at 5.0 mm penetration = 4.

The C.B.R. results are usually calculated for penetration of 2.5 mm and 5 mm. In general, the C.B.R. value at 2.5 mm will be bigger than at 5 mm, and in such a case/the previous shall be taken as C.B.R. for design point.

In case C.B.R. values on 5 mm cross that of 2.5 mm, the test should be done again. If matching results pursue, the C.B.R.value corresponding to 5 mm penetration should be in use for design.

What Is a CBR?

The California Bearing Ratio (CBR) test is a penetration test used to evaluate the subgrade strength of roads and pavements. The pressure up to a penetration of 2.5 mm is measured and its ratio to the bearing value of a standard crushed rock is termed as the CBR.

What Is a CBR Test Used For?

CBR Testing (California Bearing Ratio) is primarily undertaken to provide data for road pavement design. It was first developed by the California State Highway Department. It is a penetration test which is used to evaluate the subgrade strength primarily of roads, pavements and foundations.

How Is CBR Value Calculated?

The C.B.R. values are usually calculated for penetration of 2.5 mm and 5 mm. Generally the C.B.R. value at 2.5 mm will be greater than at 5 mm and in such a case/the former shall be taken as C.B.R. for design purpose.

California Bearing Ratio Values

The CBR value is the stress at the 0.100in (2.54mm) penetration depth. Occasionally, the ratio at the 0.200in (5.08mm) penetration depth is higher than the 0.100in depth, and the test must be rerun. If the check test shows similar results, the stress from the 0.200in penetration depth is the reported CBR.

CBR Value

The harder the surface, the higher the CBR value. Typically, a value of 2% equates to clay, while some sands may have a CBR value of 10%. High quality sub-base will have a value of between 80-100% (maximum). The CBR test is carried out on soils with a maximum particle size of 20mm.

CBR Test Procedure

The CBR test is performed by measuring the pressure required to penetrate a soil sample with a plunger of standard area. The measured pressure is then divided by the pressure required to achieve an equal penetration on a standard crushed rock material. The harder the surface, the higher the CBR value.

How to Calculate CBR?

The crude birth rate (CBR) is equal to the number of live births (b) in a year divided by the total midyear population (p), with the ratio multiplied by 1,000 to arrive at the number of births per 1,000 people.

CBR Test Procedure for Civil Engineering

CBR (California Bearing Ratio) test is a common laboratory test conducted in civil engineering to determine the strength and bearing capacity of soils. The test measures the pressure required to penetrate a soil sample with a plunger of standard dimensions. Here is a general procedure for conducting the CBR test:

- Sample collection

- Sample preparation

- Specimen soaking

- Sample compaction

- Installation of penetration plunger

- Loading setup

- Application of vertical load

- Load vs. penetration measurement

- CBR calculation

- Reporting

CBR Test Equipment Suppliers in USA

Here are a few CBR test equipment suppliers in the USA:

- Humboldt Mfg. Co.

- Gilson Company, Inc.

- Controls Group USA

- ELE International

- Cooper Technology

- M&L Testing Equipment, Inc.

- Karol-Warner

- Forney LP

- Geocomp Corporation

- PCTE – Pine Test Equipment, Inc.

CBR Test Specifications and Standards

CBR (California Bearing Ratio) is a test used to evaluate the strength and bearing capacity of soils. It is widely used in geotechnical engineering and pavement design. The CBR test measures the pressure required to penetrate a soil sample with a standard circular piston, and it is typically performed in a laboratory setting.

Here are the general specifications and standards for conducting the CBR test:

- Test Equipment

- Sample Preparation

- Test Procedure

- Calculation and Reporting

CBR Test Cost for Civil Engineering Projects

The cost of conducting a CBR (California Bearing Ratio) test for civil engineering projects can vary depending on various factors such as location, laboratory fees, equipment requirements, and the number of tests needed.

CBR Test Report Format and Interpretation

A CBR (California Bearing Ratio) test is a geotechnical test used to evaluate the mechanical strength of soils and base materials. It is commonly performed in civil engineering and road construction projects to assess the suitability of a soil or base material for supporting heavy loads.

Here is a general format for a CBR test report along with some guidance on interpretation:

- Title and Test Information

- Introduction

- Test Procedure

- Test Results

- Discussion

- Conclusion

- References

CBR Full Form in Civil Engineering

In civil engineering, CBR stands for California Bearing Ratio. The California Bearing Ratio is a laboratory test used to determine the strength and bearing capacity of soil. It is commonly used in the design and construction of roads, pavements, and other infrastructure projects.

CBR in Civil Engineering

In civil engineering, CBR stands for California Bearing Ratio. It is a measure used to evaluate the strength and bearing capacity of subgrade soils and base courses for road and pavement design. The California Bearing Ratio test is conducted to determine the penetration resistance of a soil sample under standardized conditions.

CBR Method

The CBR method, also known as the California Bearing Ratio method, is a test used in civil engineering to evaluate the mechanical strength and load-bearing capacity of subgrade soils and base course materials. It was developed by the California Division of Highways (now known as Caltrans) as a means to assess the suitability of soils for road construction.

In CBR Test the Value of Cbr Is Calculated At?

In a CBR (California Bearing Ratio) test, the value of CBR is typically calculated at a penetration of 2.5 mm or 5.0 mm. The test measures the resistance of a soil or aggregate sample to penetration under standardized conditions and is often used to evaluate the strength and load-bearing capacity of road subgrades, subbases, and base courses.

CBR Test of Soil

The California Bearing Ratio (CBR) test is a laboratory test used to determine the strength and bearing capacity of soil. It is commonly performed on soils that will be used for road construction or other infrastructure projects.

What Is CBR Value?

CBR stands for California Bearing Ratio, which is a standardized test used to evaluate the mechanical strength of subgrade soils and base course materials for road and pavement design. It is widely used in civil engineering and geotechnical engineering.

Why CBR Test Is Done?

The CBR (California Bearing Ratio) test is conducted to evaluate the mechanical strength and bearing capacity of soil subgrades, particularly in road construction and pavement design. It is widely used in civil engineering to determine the suitability of a soil for road construction projects.

Here are the main reasons why the CBR test is performed:

- Subgrade Evaluation

- Pavement Design

- Material Selection

- Quality Control

- Research and Development

What Is CBR in Road Construction?

CBR stands for California Bearing Ratio, which is a standardized test method used in road construction to evaluate the strength of subgrade soil and base materials. It measures the load-bearing capacity of the soil and provides an indication of its suitability for road construction.

Like this post? Share it with your friends!

Suggested Read –

- Plate Loading Test

- Top 10 Cement Companies in USA

- Top 10 Construction Companies in the USA

- Top 10 Construction Companies in India

- Top 10 Best Cement Companies In India 2021

- Test for Compressive Strength of Brick | Water Absorption | Dimensions Test

- First Angle Projection & Third Angle Projection Symbol (Orthographic Projection)

- What Is Lap Length | Lap Length of Column | Lap Length of Slab | Lap Length of Beam

Originally posted 2023-05-31 15:34:48.

Leave a Reply