What Is Guniting?

The process, often referred to as gunting in construction, was applicable where it was used for the stabilization of prone or sloppy areas.

Mainly purpose of this process is to heal some specific kinds of problems, like tank construction (contain water, storage for some specific chemicals), swimming pool construction, retaining wall for basement tanks, and repair works for all those.

Many other examples where it used are Slope stabilization, Dome Construction, Tunneling, Retention walls, Water tanks and pools, Artificial ponds, Ditches, and Channels, As structural reinforcement, Mining applications Dikes and dams

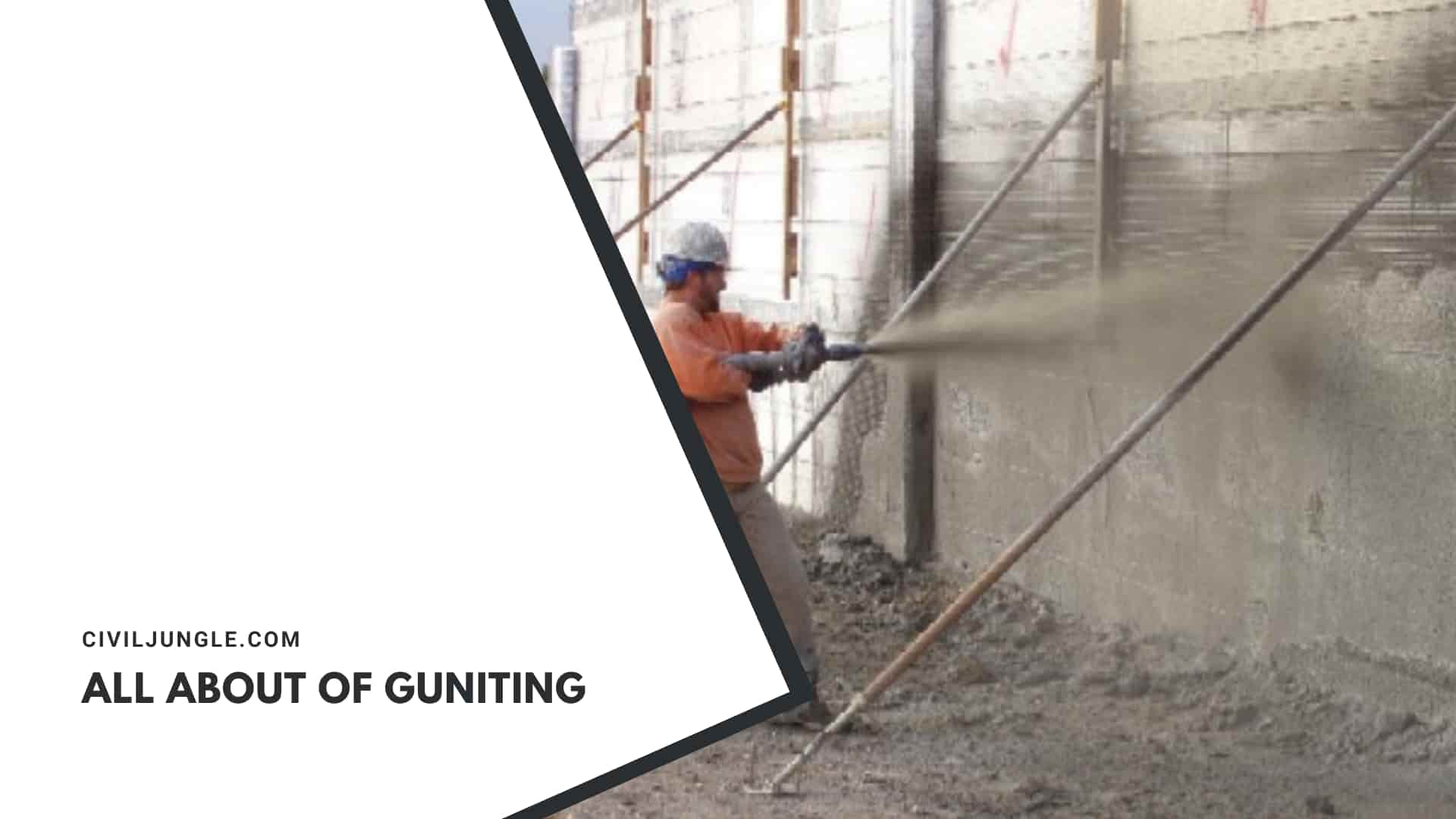

The US was the place where this process was generated first. Mostly in this process, by using a spray gun mixture of concrete or mortar applied on the surface.

The name of this method called by the mechanism of the spray gun and famous as Guniting. Afterward, technology got improve with time, and mechanism changes with its capacity, nozzle replaces the pipe.

Furthermore, the velocity of spray jet increased by using compressed pressure with intense high speed, all these developments done by the American Railway Engineers Association (in year1930), also known as AREA.

In the year 1950, The American Institute of concrete also accept this process; however, they introduce it as “shotcrete.” It was in the form of a wet or dry mix.

During those periods of time, they never use word guniting for it. Lately, the guniting name given to the process of dry How to set Guniting systems shotcreting, thus it slightly differs from guniting (like subpart).

Hardly few nations familiar with this word; on the other hand, shotcrete makes imprints among those nations.

Also, read: What is Plum Concrete | Application | Mix Design | Methodology

How to Set Guniting Systems?

The mixture made by dry content mixed in a place known as bin and cement gun stored mixture. When the mixture is ready to apply on the surface, under the control pressure and intense high velocity, mixture hit the surface after water addition in it and passed through a nozzle.

Afterward, it’s released to hit on the surface. The pressure generated in water flow by using the water tank, which releases water at adequate pressure to the nozzle, thus this high-pressure flow throw mixture.

Cautions to Set High Quality in the Process of Guniting :

- Firstly, before applying it on the surfaces or areas of application, we have to clear it by using the sandblasting method; mostly, it used to remove the steel surface, which affected by the rust due to various reasons.

- There are many kinds of mixer proportions used to make guniting, mostly 1:3 and 1:4:5 percentages acceptable for it. A strength of this mixture is nearly 70MP when it measured on the 7th day of applications. Moreover, 0.30 is its WC(water-cement) ratio.

- The quality and guniting work rate through this process depend on many factors, primarily the skillful operators and controllers of the nozzle.

- In some cases, make sure that this guniting process is applicable after 6 hours of surface treatment.

- Mostly surface cleaning processes are done by using a high-pressure water jet or by adopting the air blast method according to circumstances.

- Some materials like grease, mud, dirt, or any other materials.

- One condition that must be followed during the making of the mixture is the size of the aggregate should be less than 10mm.

- To increase life validity, make sure that mortar quality must be high or according to its set criteria of manufacturing.

Also, read: What Is Honeycomb In Concrete | Cause | Cure | Type of Grouting

How It Works and Requires Things of Guniting?

It works on a mechanism system, which includes a jet pipe or nozzle used to throw the material on the surface at high velocity and compressed pressure.

This mixer made by adding water according to the requirement of concrete mix, a combination of this dry material and water ready to apply on the surface.

The water used to make that combination is on an accurate level, and it also controls by manually. Mostly cement mortar mixture used as the mixture for Guniting, and mixture manufacturing of mixture depends on where it applies and area of applications.

Source: This video provided by Rinkit Bhavshar, He is working as Project Eng at City Gate (Ahmedabad).

Disadvantage of Guniting.

Sometimes this method is not accepted due to its highly skilled moreover experienced workers in this field, which causes high pay rates and extra cost burden on the budget. The finishing of this process depends on the operators’ skilled.

Most of the time, due to the high pressure throws of the mix on the surface, the content of the mortar mix gets spread, and it’s too hard to set it back on leading foam — other things like wasting of material due to bounce again with high velocity outside of the area.

Also, read: What Is Workability of Concrete | Factors Affecting Workability | Test |Errors

Advantage of Guniting.

Adaptations of this method are very high due to its traits of versatility. This method is also preferable in many areas of construction, which known as hard to build like some spherical structures or arches due to all this in some particular arrangement of creating caves, swimming pools, artificial waterfalls, where it’s too hard to use workforce to for concreting.

There are examples, like building tunnels for rail works, pipelines, underground canal, reservoirs, etc. To sum up, all these kinds of various features make it highly preferable in all prospects.

All the mechanism used in this process is too handy to use. Furthermore, it operates and controls with ease hence more preferable in this sector.

At the time of application of this method, the operator can easily adjust all things very quickly; thus, the results of this method will be more accurate.

When compared with the dry-mix shotcrete or the guniting mix to the wet shotcrete process, it can be set speedily.

If it is damp mix, segregation or sagging or sticking will be troubled due to its height of applications. Mostly this method is beneficial in overhead construction.

When this method is applicable in very nominal works like filling heir lock cracks, for small repair works of coating o surface, for all these types of jobs, this method is adaptable.

This method is always recommended to use in the following circumstances. It can be mixed with steel fiber as a replacement for welded wire mesh, offering better flexural strength, flexibility, and toughness, generally less expensive than traditional concrete, reduced shrinkage and lower permeability

Guniting is the best preferable choice for all those kinds of works were an unpredicted work stoppage is possible.

Guniting

Guniting, often referred to by its guniting meaning as a process used in construction for the application of slope stabilization and certain rehabilitation purposes, is mainly utilized in the construction of retaining walls, swimming pool construction, tunnel construction, in fluid tank construction, and some of the concrete repair works.

What Is the Process of Guniting?

he cement is mixed with slightly moist sand and then necessary water is added as the mixture comes out from the cement gun. A regulating valve is provided to regulate the quantity of water. The surface to be treated is cleaned and washed.

What Is Guniting and Grouting?

“Gunite, sometimes referred to as gunniting, is also known as shotcrete or pneumatically applied mortar. Gunite is a mixture of Portland cement, sand & water, shot in to the place by compressed air. Guniting is primarily used in swimming pools, dams, guniting wall constructions, tanks, etc.

Is Gunite the Same as Concrete?

Firstly, unlike concrete, which uses large and small aggregates, gunite only uses small particles. As we stated earlier, concrete comes ready mixed. With gunite, on the other hand, a dry mix is fired through a hose with the water being added at the point of delivery.

Guniting Work

Gunite, often known as guniting concrete, refers to an artificial mixture of cement, water, and sand that is applied to a mold to produce a dense hard protective layer. Gunite is used to line tunnels and structures and for construction applications, such as sealing cracks, fissures and areas that could be sources of leaks and/or structural instability.

Like this post? Share it with your friends!

Suggested Read –

- Types of Tunneling

- What Is Lintel | Type of Lintel

- What is Consistency of Cement

- Difference Between One Way Slab and Two Way Slab | What is Slab

- Mortar Vs Grout | What Is Motor and Grout | Type of Motor and Grout | Difference Between Mortar and Grout

- Detail of Beam Connection | Simple Framing Connection | Semi-Rigid Framing Connection | Rigid Frame Connection

Originally posted 2021-10-25 08:42:59.

There is certainly a lot to find out about this subject. I love all of the points you ave made.