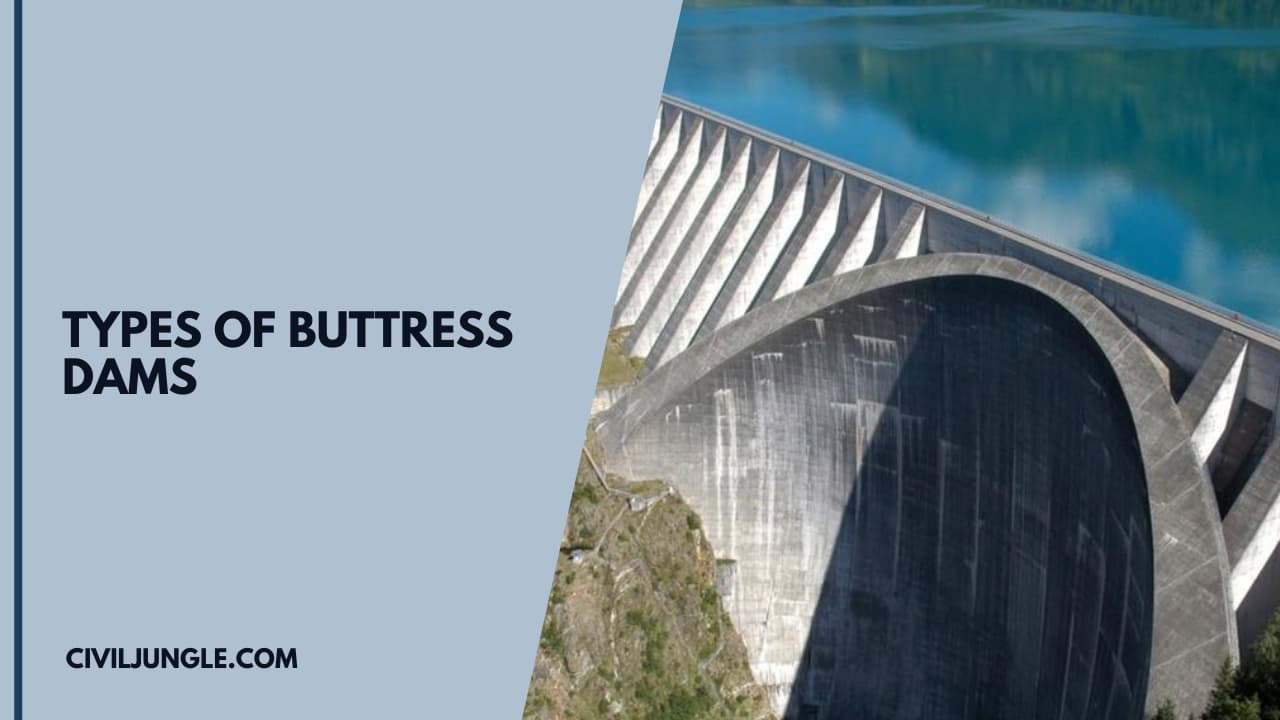

What Is a Buttress Dam?

Important Point

The buttress dam is a variation or improvisation of the Gravity Dam. Buttresses are just like concrete walls that are built parallel to the flow of water with such a prescribed thickness at frequent intervals. An arch slab or angled deck slab is installed on such buttresses to sustain upstream water.

Typically, the Gravity Dam needs more concrete action. To mitigate costs, the amount of concrete shall be reduced by extracting this from the unstressed section of the dam. Eventually, a vital breakthrough is taking place, that is buttress dam.

Also, Read: What Is Bridge Abutment | 5 Types of Abutments

Types of Buttress Dams

There have been five different types of dams, from which the deck slab form and multiple arch types were often widely found. The five are as mentioned.

- Deck Slab Buttress Dam.

- Multiple Arch Buttress Dam.

- Massive Head Buttress Dam.

- Multiple Dome Buttress Dam.

- Columnar Buttress Dam.

1. Deck Slab Buttress Dam

There is a deck slab for this form of a dam that is protected by the corbels of the buttresses. Some of this dam is usually built between 20 to 50 meters in lower levels.

The slab given is angled to the horizontal position by approximately 40 to 55 degrees. This inclination is necessary to strengthen the dam and to sustain the dead weight of the deposited reservoir water, but also to keep the dam from slipping.

Throughout this case, every other deck slab system on two adjacent buttresses functions as a single independent unit. Therefore, whether one unit is affected or destroyed, there is no need to think about the other units.

The design of the Deck Slab Buttress Dam is the same as the Gravity Dam factors. Perhaps, throughout this situation, we’ve got three forms and they’re.

- Fixed Deck Slab.

- Free Deck Slab.

- Cantilever Type.

1.1. Fixed Deck Slab Buttress Dams

In the case of fixed deck slab form dam, the deck slab as well as the buttresses are built monolithically.

1.2. Free Deck Slab Buttress Dams

This is often named the simple deck slab buttress dam. These are built where the base soil is really thin. Throughout this scenario, reinforcing is given on the downstream side of the deck slab.

1.3. Cantilever Type Buttress Dams

Throughout this scenario, the deck slab is cantilevered across both ends as well as the upstream face is reinforced.

Also, Read: What Is Bridge | Components of Bridge and Their Function

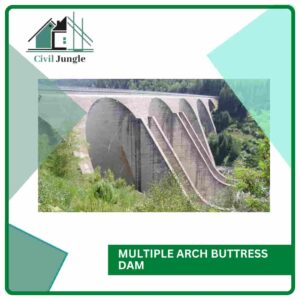

2. Multiple Arch Buttress Dam

Multiple arch dam contains an arrangement of arches and for this situation, arch slabs are given at the upstream substance of the dam. These slabs are upheld by buttresses. The buttress divider is developed as a single hardened divider or a twofold empty divider.

This kind of dam can be liked for bigger statures about in excess of 50 meters. When contrasted with deck slab type buttress dams, multiple arch buttress dams are more adaptable and stable.

The primary burden for this situation is the nearby buttress units relies upon one another. In this way, in the event that one unit gets influenced, it causes extreme issues for the entire arrangement of arches. To conquer this great establishment for every one of buttresses divider ought to be given.

The thickness of the arc given differs in the case of high stretch and is consistent in the situation of short length. The central angle of the arch will be between 180 degrees and 150 degrees.

The distance between the buttresses will be between 15 and 21 meters. That being said, some attention can also be given to greater spacing.

3. Massive Head Buttress Dam

In the same kind of buttress dam, there is no slab or arch on the upstream face, rather than the buttress head, which is widened and joined to the corresponding buttress head. Such as this one, all buttress heads make the area solid, promoting water.

The expansion of the buttress heads may be achieved in various forms, such as rounded, diamond shapes, respectively. Thus, such forms can withstand water pressure very well. The linking of the heads is enhanced by the provision of copper strips.

Construction of large head buttress dam is simpler comparison to other methods but no strengthening is needed, only bulk concrete is spread all over the dam body. Because of a very massive concrete body, it’s indeed thicker and avoids slipping.

Also, Read: Difference Between Bridge and Culvert | What Is Bridge | What Is Culvert

4. Multiple Dome Buttress Dam

This is quite identical to the multiple arch type buttress dam, except in this scenario the domes are built in the places of the arches. Besides, nearly all the functions are the same.

The requirement of these kinds of domes influences the establishment of a greater spacing between all the buttresses. It is also possible to have a longer span and therefore to reduce the number of buttresses.

5. Columnar Buttress Dam

Throughout the situation of the columnar buttress dam, the inclination columns protect the floor of the dam. It’s a variation of the deck slab-style buttress dam.

It needs a very solid and secure base. It also needs qualified individuals to develop underpinnings. Therefore, the dam is not commonly used.

Also, Read: What Is Grouting | Types of Grouting | Advantage of Grouting

Advantages of Buttress Dam

- The buttress dam would be less huge than the Gravity Dam. The buttress dam may well be built on even a comparatively thin basis over which the Gravity Dam could not be built.

- A wide vertical water pressure feature, which adds to the improvement stabilization of the dam which preserves concrete, is built on the upstream face of the buttress dam.

- The safety factor in the situation of the buttress dams is considerably greater than that of the gravity dams.

- Because ice continues to slip across the inclined U/S surface, there is little importance to the ice strain.

- The height of the buttress dams can be raised by stretching both the buttresses and the deck slab.

- Powerhouses or even other plants may be situated in the open space in between buttresses.

- The expense is not minimized by the very same ratios as the additional cost of formwork and strengthening is necessary.

- According to the gap between the buttresses, the backspace of the deck slab can be reached.

- Periodic examination of foundations, respectively. maybe taken out by approaching this stage.

- Although the exposed surface of the concrete is more but the amount of concrete is less than the gravity dam, the excess heat throughout construction is best accomplished.

- The speed of the building can also be improved as thinner parts do not pose any problems for cooling.

- The dispersing of the buttresses might be changed in accordance with use zones of good foundations

- Buttress dams can be intended to oblige moderate measures of establishment development without genuine harms, along these lines it tends to be underlying the dirt with differential settlements.

- The measure of concrete needed for a buttress dam is around 1/3 to ½ of the concrete needed for a gravity dam of similar stature.

- Access is conceivable to the rear of the upstream essence of the dam and to the establishment between buttresses for occasional investigation and for resulting grouting and boring pressing factor depended on openings, whenever required.

- The uplifting strain at the buttress dam is significantly lower, which adds to the economy of the concrete and overall stabilization of the dam.

- Powerhouse, switchyard, respectively, may be situated between the buttresses, reducing some building costs.

Also, Read: Live Load Vs Dead Load | What Is Load in Civil

Disadvantages of Buttress Dam

- This is since the thickness of the slab is quite limited although there is access to the end of the slab via the gap between the buttresses.

- Skilled labor standards and a shutter to concrete proportion are higher for the buttress dam than with the Gravity dam. This will contribute to a higher unit cost of concrete.

- Decline of the upstream surface of the comparatively thin reinforced deck slab or arch of the buttress dam has much more drastic effects on the integrity of the dam;

- The volume of water sealing to be established and preserved for the buttress dam is normally higher than for other dams.

- The stress of the foundation is greater, indeed a sound rock foundation is appropriate or a spread base or a continuous mat might be needed, which would increase the cost of building.

- The savings due to a decrease in the quantity of concrete would also, to some degree, be compensated by the need of strong reinforcing for comparatively thin members of the buttress dam.

- The buttress dams are more vulnerable to intentional destruction than the strong gravity dams.

Also, Read: Difference Between Formwork, Shuttering, Centering, Staging & Scaffolding

Application of Buttress Dam

- To have a ‘enhanced dam structure using the buttress walls as well as the buttress heads in which the front face of the buttress head is covered by a waterproofing material.

- Also provide enhanced dam of the buttress kind in which the buttress head is a longitudinal direction and separated by a joint allowing contraction across defined lines.

- To have a river that’s headed. Buttress walls in which the heads are separated by a bridging construction that bridges the gap between the heads and provides that very link between both the bridging construction as well as the buttress heads that perhaps the forces transmitted by the bridging constructions to the heads are distributed by direct compression so that at least, if any, bending moments in the heads are created.

Buttress Dam in India

Meer Alum Dam is the only dam in India. Which is Buttress Dam.

The remarkable multi-arch Mir Alam dam was constructed for the water system of Hyderabad in 1804. This dam became undoubtedly the work of Henry Russel, a participant of the British Royal Engineers.

The frame, which reached a maximum of 12 m, consisted of 21 semicircular vertical arches of constant thickness and varying span. It was 100 years before a dam with a similar design was completed. The Mir Alam Dam should therefore be regarded as one of the exceptional, genuine strokes of genius!

Also, Read: Tension Vs Compression | What Is Tension & Compression

Buttress Dam

A buttress dam or hollow dam is a dam with a solid, water-tight upstream side that is supported at intervals on the downstream side by a series of buttresses or supports. The dam wall may be straight or curved. Most buttress dams are made of reinforced concrete and are heavy, pushing the dam into the ground.

Buttress Dam in India

Buttress dams in India are of three types: (i) Deck type, (ii) Multiple-arch type, and (iii) Massive-head type. A deck type of buttress dam has a sloping deck supported by buttresses. Buttresses‘ walls are the ones that are triangular in shape. They transmit the water pressure from the deck slab to the foundation.

Types of Buttress Dams

- Deck Slab Buttress Dam.

- Multiple Arch Buttress Dam.

- Massive Head Buttress Dam.

- Multiple Dome Buttress Dam.

- Columnar Buttress Dam.

Advantages of Buttress Dam

The uplift pressure acting on a buttress dam is considerably less which leads to economy in the concrete and overall stability of the dam. The powerhouse, switchyard, etc., can be located between the buttresses thus saving some cost of construction.

Disadvantages of Buttress Dam

- Buttress dam requires more for work than solid concrete dams.

- As the thickness of the upstream concrete surface is less, it is more liable to get deteriorated.

- It requires constant maintenance and supervision.

- Life of the dam is less as compared to other dams.

Application of Buttress Dam

Buttress or hollow gravity dams were originally built to retain water for irrigation or mining in areas of scarce or expensive resources but cheap labour. A buttress dam is a good choice in wide valleys where solid rock is rare.

The Other Name of Buttresses Dam Is

A buttress dam or hollow dam is a dam with a solid, water-tight upstream side that is supported at intervals on the downstream side by a series of buttresses or supports.

What Is Buttress Dam?

Buttress dams are commonly used in areas where the foundation of the dam is not strong enough to support the weight of a solid gravity dam, or where there is a narrow canyon that requires a more efficient use of space. They are typically used for smaller to medium-sized dams, ranging in height from a few meters to over 200 meters. Buttress dams can be found all over the world and are often used for hydroelectric power generation, irrigation, and flood control.

Buttress Dams Are of Types

A buttress dam can take many forms, such as a flat slab or a massive head buttress. Ambursen dam. A buttress dam in which the upstream part is a relatively thin flat slab usually made of reinforced concrete.

Buttress Dam Definition

Buttress dams are concrete or masonry structures usually comprising inclined panels or arches supported by buttresses. From: Encyclopedia of Physical Science and Technology (Third Edition), 2003.

Concrete Buttress Dam

A concrete buttress dam is a type of buttress dam that is constructed using concrete as the primary material. It is designed to withstand the force of water and to provide support for the weight of the dam.

Buttress Dam Example in India

One example of a buttress dam in India is the Bhadra Dam, located on the Bhadra River in the state of Karnataka. It is a concrete buttress dam that was completed in 1965 and has a height of 59.13 meters and a length of 225 meters. The dam is designed to provide irrigation and hydroelectric power to the surrounding areas.

Deck Type Buttress Dam

A deck type buttress dam is a type of buttress dam that is constructed with a concrete deck on top of the buttresses. The deck is usually supported by beams that are anchored to the buttresses. The space between the buttresses is filled with a material such as concrete, earth, or rock to create a solid wall that holds back the water.

Types of Buttress

- Multiple Arch Buttress Dam

- Embankment Buttress Dam

- Deck Type Buttress Dam

- Hollow Buttress Dam

Massive Head Buttress Dam

Massive Head Buttress Dam

In this type of buttress dam, no slab or arch is provided at the upstream face, instead of that buttress head is enlarged and joined with adjacent buttress head. Like this all buttresses heads makes strong water supporting surface.

Buttress Dam Allows to Release

A buttress dam allows for the controlled release of water through spillways or gates. Spillways are channels or openings built into the dam structure that allow excess water to flow out of the reservoir when the water level rises too high. Gates are mechanical devices that can be opened or closed to control the flow of water.

Multiple Arch Type Buttress Dam

A multiple arch type buttress dam, also known as a multiple arch dam, is a type of buttress dam that consists of a series of buttresses with arches between them. The arches act as supports for the water load, allowing for a thinner and more efficient dam profile. The design of a multiple arch dam is similar to that of a multiple arch bridge, with each arch acting as a separate load-bearing element.

Dam Buttress

A dam buttress is an architectural element that provides support to a dam structure. Buttresses are commonly used in concrete dams to counteract the horizontal force of the water pressure against the dam’s vertical wall. By distributing the water pressure to the ground, buttresses help prevent the dam from tilting or collapsing.

Butress Dams

A buttress dam is a type of concrete dam that uses a series of reinforced concrete buttresses to support the weight of the dam and the water load. The buttresses are built on the downstream side of the dam and transfer the water pressure to the ground, which helps prevent the dam from being pushed over by the force of the water. The buttresses can be arranged in a straight line or in a zigzag pattern, depending on the specific engineering requirements of the project.

Like this post? Share it with your friends!

Suggested Read –

- Earthen Dam

- Types of Tunnel

- Types of Spillways

- Solid Gravity Dam

- Top 10 Cement Companies in USA

- Top 10 Best Cement Companies In India 2021

- Top 10 Bathroom Fittings & Sanitary Brands India

- What Is Grouting | Types of Grouting | Advantage of Grouting

- What Does Parapet Mean | Types of Parapet Wall | Uses of Parapet Wall

- Cinder Block Vs Concrete Block | What Is Cinder Blocks | What Is Concrete Blocks

Originally posted 2023-05-03 18:40:27.

Leave a Reply