What Is MDF?

Important Point

MediumDensity Fiberboard, often referred to as MDF, is a form of composite wood material. Many wonder about the properties of mdf and its advantages and disadvantages. Wood residues are being used to start making the MDF board.

It is widely used in furnishings attempting to make both residential as well as commercial construction. MDF is cost-effective and expenses a fraction of the cost of natural wood.

It is therefore a lower-cost replacement for natural wood. You get a natural wood looks without having to spend money on expensive wood. MDF is the expenditure of most people.

Also, Read: Top 15+ Best Plywood Brands in India

MDF Material

When discussing mdf meaning, it’s essential to note that MDF Material is traditionally made of wood fibers that have been broken down into residuals, then mixed with wax and resins and heat pressed into dense, durable sheets. A sheet of MDF will be heavy, smooth, and even, with a flat surface that can be painted or sealed

What Is MDF Board?

MDF, which stands for Medium Density Fiberboard, is a high-grade, composite material. It’s crucial to understand both the mdf advantages and disadvantages. It is made from recycled wood fibers and resin.

It is dried and pressed to produce dense, stable sheets. Because of this process, MDF does not warp or crack like wood. And since MDF is made from small particles, it doesn’t have noticeable grain patterns.

This will result in a smoother finish on the cabinets. MDF is also less expensive, which is sometimes a big selling point for some people. Depending on budget, others are willing to spend the extra money to purchase the all wood cabinets.

Advantages of MDF Board

- One of the primary mdf advantages is its economic value for average citizens as it is cheaper and cheaper. So, they’re beyond everyone’s scope to buy. You may normally purchase MDF at a fraction of the cost of buying actual wood. By opting to use medium density fiberboard in some parts of the building, you can save money on other items. This offers you a lot of versatility when it comes to the budget of your project.

- 100% recycled material is used, which ensures that no tree is chopped down, meaning that it is environmentally safe.

- MDF is easy to label in a range of colours and is simpler to mold than solid wood. The MDF process is simple to complete. All sorts of colour, paint may be uniformly coated on the MDF is the ideal substrate for the result of painting.

- MDF is a highly engineered device. So it doesn’t have any grain. MDF does not provide ties which can bleach the ground of a piece or make it impossible to mount parts. That’s why it’s easy to cut and drill without the chance of injury. Its density makes it ideal for robots as well.

- MDF is resistant to termites and other insects due to the chemicals used in its construction during the manufacturing process.

- In comparison to natural wood products such as doors, MDF will not expand and contract in heat and humidity.

Also, Read: MDF vs Plywood | What Is MDF | What Is Plywood

Useful Article for You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is a Frame Structure

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is Mdf Mean

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is SuperelevationWhat Is Overhang

- What Is Sand Blasting

- What Is a Span Bridge

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- Different Types of Beam

- What Is Pedestal

- What Is Plumbing Fixtures

- What Is Slab Construction

- What Is Calacatta Quartz

- What Is Auxiliary View

- Rcc Rates

- Sheepsfoot Roller

- Live Load Vs Dead Load

- What Is 1 Flight of Stairs

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- Arch Foundation

- What Is a Stair Landing

- What Is Stone Masonry

- What Is a Spandrel Beam

- What Is Pier and Beam Foundation

- What Is Levelling

- What Is a Pile Cap

- What Is a Mat Foundation

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is Modulus of Rupture

- What Is a Flush Door

- What Is Residential Construction

- What Is the Best Foundation for a House

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is a Monolithic Slab Foundation

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is a Tremie

- What Is Tributary Area

- Cbr in Road Construction

- What Is Shoring Construction

- What Is a Cason

- What Is Wall Putty

- What Is the Difference Between Mortar and Concrete

- What Is Bhk

- What Is Sbc of Soil

- What Is Plinth Level

- What Is Water Proofing

- What Is Mix Design of Concrete

- What Is Fine Aggregate

- What Is Retention Money

- What Is Design Mix

- What Is Isometric Scale

- What Is Development Length

- What Is Superelevation

- What Is Wall Made Of

- What Is Micro Piling

- What Is Soil Stack

- What Is a Half Wall Called

- What Is Flagstone

- What Is a Cinder Block

- What Is Plinth

- What Is Floors

- What Is a Parapet in Construction

- What Is Concept Drawing

- What Is a 30 Degree Angle

- What Is a Mezzanine Level

- What Is Plinth Area

- What Is a Highway Flyover Tunnel

- What Is the Top of the House Called

- What Is Tensile Strength of Concrete

Disadvantages of MDF Board

- When considering mdf wood disadvantages, it’s evident that MDF is made of wood which be degassed during building, although this has mostly drained away by the completion of the development process. The decorated MDF therefore eliminates any health hazard.

- MDF will expand if the water is hit. MDF extracts water faster than timber.

- MDF needs to be heavily maintained – once MDF is broken or damaged, this can be quickly restored or sealed.

- The additives used to make MDF make the substance less child-friendly than most fabrics.

- MDF is softer than natural wood and is not built to withstand extreme stress. It is vulnerable to breaking or breaking up under extreme tension. Long load-bearing The durability of MDF furniture is smaller than that of natural wood furniture.

MDF Board Uses

Understanding the properties of mdf wood and mdf characteristics helps in recognizing its uses. Due to the smoothness of Medium Density Fiberboard (MDF), it can be easily painted, cut, and shaped, creating it an outstanding mater.

Medium Density Fiberboard (MDF) is a specially engineered commodity that is generated from wood fibers. It is a dense commodity and has various uses in a variety of industries.

Fiberboard is a well-built product and is often coated with a veneer and it can also contain secondary raw materials such as fibers from sugarcane and wood chipping.

Common Uses Of MDF Board are as follows,

1. Uses of MDF Board: Cabinetry

An additional thing that normal density fiberboard is known for is home interior cabinetry. It is most common to discover cabinets made of fiberboard and then completed with solid wood laminate on top.

Home interior commodities like kitchen cabinets and shelving units are generally built from Medium Density Fiberboard(MDF) and this also contains doors, moldings, and sometimes even flooring such as wood impact laminates.

There are several different applications that can be combined with using Medium Density Fiberboard (MDF) and these are only limited examples of how it is utilized in home interiors.

2. Uses of MDF Board: Fire Resistance

One interesting usage for medium density fiberboard that several people may not be conscious of is its fire retardant capabilities. Specific buildings and structures expect the use of fire retardant MDF Board in their construction.

This type of fiberboard is perceived to be used in the construction of commercial buildings which contain stores and offices and different buildings that must fulfill certain building legislation and requirements for safety.

Some homeowners select to utilize fire retardant MDF Board in the construction of the new homes as well as to furnish further safety from any possible fires spreading.

3. Uses of MDF Board: Vapour Repulsion

Medium-density fibreboard can be also utilised as a vapour obstacle and insulation for both residences and commercial buildings. This is because it has durability and procedure that makes it an excellent vapour obstacle when utilised with additional vapour repellant products.

This type of wood is prepared to deal with the big periods of moisture and drying out without occurring damaged like shrinking or going through the method of rotting.

It can be an act as a vapour obstacle and it can also give insulation and avoid heat loss which would finally help with lowering heating expenses and electrical bills.

4. Uses of MDF Board: Soundproofing

This may not be as widely recognised, but fiberboard can also give soundproofing and reduce the ability of sound to travel. Several speaker manufacturers utilize medium-density fiberboard or particleboard because it consumes sound and prevents vibration from inside the speaker case.

This wood commodity can also be utilized in media rooms, walls of apartment buildings and offices as well as the floor underlayment to enable minimize sound disruptions and noise pollution.

Several different contractors and building firms use MDF Board for this specific purpose during construction for the requisition of decreasing noise and sound traveling.

5. Uses of MDF Board: Furniture

This is an extremely versatile material to work with and the various practical uses for Medium Density Fiberboard (MDF) and what you can do with it.

To begin with, several different furniture companies utilise specially assessed Medium Density Fiberboards and if you have always purchased an economical piece of furniture like a bookshelf or an entertainment center, therefore chances are they may be constructed from MDF.

Several different economical furniture pieces are constructed from low to medium density fiberboard because this special product is easily manufactured and is inexpensive, which lowers the cost of manufacturing and production.

Obtaining low-density fiberboard typically decreases the costs connected with manufacturing furniture and it is a very popular material that is used in the creation of prefabricated furniture.

Companies like IKEA and different big store companies give products that are manufactured from this material.

6.Uses of MDF Board: Roofing

Another interesting truth about the versatility know that fiberboard is usage around the home both the inside and outside. Fiberboard can be utilized for all types of housing desires comprising roofing materials for low sloped roofs.

Medium Density Fiberboard is an outstanding material that can be utilized as backing for shingles of any type of roof. You can also utilize it as sheathing for walls inside your home.

Medium Density Fiberboard is extremely durable as well as flexible which provides it multiple applications when it comes to a family home both in the interior and exterior.

Finally, medium density fibreboard is a top-notch solution with many various uses and aspects that it can be utilized for. This list of popular practical usages of Medium Density Fiberboard (MDF) is just a brief example and there are plenty of more uses of Medium Density Fiberboard (MDF) that can be utilized for.

It will continue to be an inexpensive option rather than buying timber commodities such as plywood and with its various uses, it will ever be a well-known and widely utilized material in the fabrication of furniture all the path to the construction of buildings and homes.

MDF Board Properties

- Thickness

- Elasticity

- Water Absorption

- Swelling

- Internal Bond Strength

- Modulus of Rupture

- Modulus of Elasticity.

Application of MDF Board

- Furniture

- Cabinets and Shelves

- Flooring

- Decorative projects

- Speaker boxes

- Wainscoting

- Doors and door frames

- Tradeshow booths and theater set construction.

Useful Article for You

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Cmu Wall Meaning

- Gradient Road

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- Well Points

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

- How Heavy Is Dirt

- Tender Meaning in Architecture

- Dark Olive Green House

- Cast in Place Concrete

- Lean to Roof

- How Tall Is an Average Door

- Grade Beam Foundation

- Window Sill Height

- Concrete Cold Joint

- Types of Traps

- Types of Pipe

- Wood Supporting Beams

- Finishing Plaster

- Home Depot Scrap Wood

- Lvl Beam Size Calculator

- Structural Shell

- Curb Types

- Msand

- Optimum Dry Meaning

- Disadvantages of Low-E Glass

- Bridge Abutment Definition

- Build Materials List

- Composite Masonry Wall

- Is Cedar a Hardwood or Softwood

- Modified Proctor Test

- Physical Properties of Sand

- Sugar in Concrete

- Crane Machine Construction

- Types of Gable Roofs

- Door Frame Types

- How Much Does 55 Gallons of Oil Weigh

- Dog Leg Stairs

- Concrete Salt Finish

- Westpoint Bridge Builders

- Types of Porches

- Hempcrete Disadvantages

- Roof Pitch Types

- Types of Weirs

- Asphalt Floor

- Dutch Roof

- #6 Rebar Weight Per Foot

- Prizmatic Compass

- Bond Break Concrete

- Poured Concrete Wall Cost Calculator

- How Many 60 Lb Bags of Concrete in a Yard

- Wood Fence Post Spacing Chart

- Falsework

- Design of Building Structures

- Topping Slab

- Types of Cinder Blocks

- Fresh Concrete

- Door Colors for Red Brick House

- Foundation Spalling

- Clear Cover Concrete

- Tiles Brand

- Cement Consumption in Plaster

- Aggregate Density Kg M3

- Weight of Concrete Slab Calculator

- Is Clay Smaller Than Silt

- How to Calculate Dead Load

- Bad Concrete Work

- Stepped Foundations

- Residential Construction Cost Estimator Excel

- Different Construction Trucks

- Septic Pump Replacement Cost

- Dead Load Calculator

- Beam Vs Column

- What Type of Slope Failure Is Shown in This Figure

- Types of Soffit

- Olive Green House with Brown Trim

- Tie Beam Concrete

How to Waterproof MDF Board?

Given the mdf disadvantages related to moisture, it’s essential to know how to waterproof it. They can make durable MDF by applying high-quality wood sealant, varnish or stain or weather-proof paint such that your design can survive the hazard of moisture and moisture.

Should not use waterborne polyurethane, since it can not be conveniently attached to the surface of the MDF.

You would need to start with a latex primer or an MDF-specific primer. Using a 3/8-inch paint roller to add the primer and a paintbrush to hit any places that cannot otherwise be touched. Enable the primer to dry for six hours.

Step two is to apply a sealant or waterproof paint with a 3/8-inch roller. Use a paintbrush to paint the edges and corners. The layer should take about four hours to dry.

Step three is your final layer of paint or sealant; allow at least three days of drying to make the MDF moisture resistant.

What Is MDF Made of?

When people inquire about the mdf meaning, they often want to know its composition. MDF is produced by disintegrating both hardwoods and softwood into wood fibers, with MDF generally comprised of 82% wood fiber, 9 percent urea-formaldehyde resin glue, 8 percent water, and 1 percent paraffin wax.

The density is usually among 500 kg/m3 (31 lb/ft3) and 1,000 kg/m3 (62 lb/ft3). The range of density as well as categorization as light, specification, or high-density boards is misnomer and confusing.

The density of its panel, once assessed in regards to the density of the fiber that ends up going into the panel, is important.

In the scenario of softwood fiber panels, a dense MDF panel with a density of 700–720 kg/m3 may be termed “ density, while a board of the very same density created of hardwood fibers also isn’t considered an important density.

Fiber Production For MDF

- The unprocessed elements that make up a piece of MDF must undergo some certain procedure before they become appropriate. A large magnet is used to eliminate any magnetic impurity and the materials are kept separate by size. The materials will then be compacted to drain the moisture but instead fed into the refiner, which crushes them into small pieces.

- Resin would then be implemented to improve bind the fibers. This combination is put in a very huge dryer that is heated by gas or oil. This dry mixture is run via a drum compressor fitted with automated systems to ensure proper density and strength. The subsequent pieces are therefore cut to the appropriate length with the manufacturing saw while still warm.

- Fibers are processed as individual but intact fibers and vessels, produced in a dry process. The chips are then compacted into small plugs using a screw feeder, heated for 30–120 seconds to soften the lignin in the wood and then fed into a defibrator.

- A typical defibrator consists of two counter-rotating disks with grooves in their faces. Chips are fed into the center and fed outwards between the disks by centrifugal force.

- The decreasing size of the grooves gradually separates the fibers, with the help of softened lignin between them. The pulp wants to enter a ‘blowline’ from its defibrator, an unique portion of the MDF procedure. This is an expanded circular pipeline, originally 40 mm in diameter and up to 1500 mm in diameter.

- Wax is infused during the first step, that also coats the fibers and is distributed equally by the turbulent motion of the fibers. The urea-formaldehyde resin is then infused as the primary bonding agent. Wax enhances moisture resistance as well as the resin originally significantly reduces clumping.

- The substance dries in the final heated blowline expansion chamber and expands into a fine, fluffy, and light fiber. This fiber may be used or stored immediately.

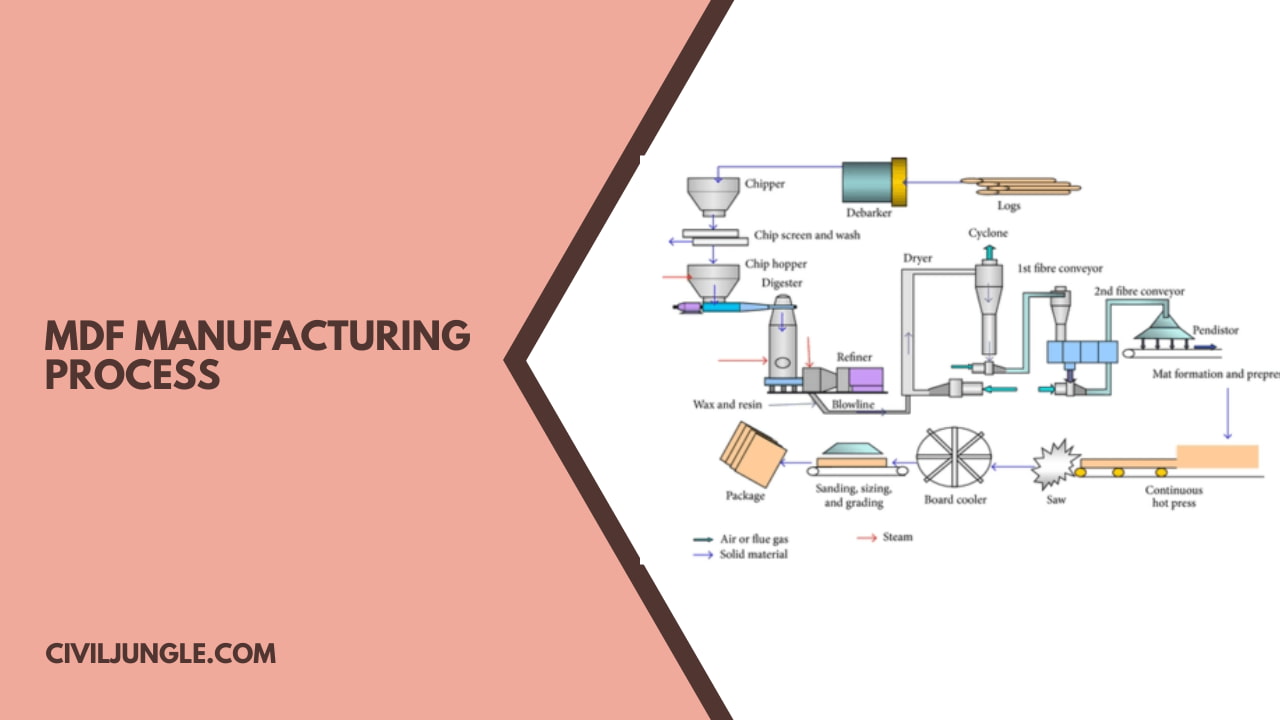

MDF Manufacturing Process

It involves some process, such as:

- Collection.

- Wood preparation.

- Resin recipes.

- Press technique.

- Panel sanding technique.

- Finishing.

Step 1. Collection

The first stage of wood processing is the collection and grinding of raw materials or wood residues. Chips and shaves are harvested from sawmills and plywood plantations.

Debarking is achieved while softwood is used (eg. Eucalyptus sp.). Debarking decreases agricultural waste and grits and improves fine grinding. If required, the softwood shall be trimmed and re-sliced. A chopper can be used for this purpose.

Step 2. Wood Preparation

Impurities are separated using magnetic metal. The substance is divided into large lobes and small pitches. The remaining metals are isolated by a magnetic detector. Picked fibers are submitted to news. For this purpose, a side-screw feeder and a plug screw feeder are used.

Water is collected which has an essential role for it. The refiner tears the substance into functional fibres. Foreign items are removed by massive motor units.

Step 3. Curing and Pressing

The resin is applied after processing to reduce the resistance of formaldehyde and the catalyst is added after refining. The quantity of resin shall be controlled by the volume required. The scalping roll is used to render a mat or pad with a uniform thickness.

Compression is performed in a couple of stages. They are sliced or trimmed before final processing. A bigger drum is used to compact it onto a single mat or pad. The resulting board is cut before cooling.

Step 4. Panel Sanding

The finished panels are sanded to a flawless surface. Belts are used and abrasive coating is found. Various ceramic abrasives, such as zirconium alumina, aluminum oxide, are used.

In comparison, silicon carbide is used for smoother surfaces. Double-way grading is performed to boost accuracy. Anti-static equipment is used to discourage the use of static energy during construction. Static electricity can create excess dust.

Step 5. Finishing

The very first step of the finishing process is cutting. MDF changes depending on the consistency specifications of the finishing stages.

A variety of shades, a range of wood grains, is seen. For cutting in various shapes, different cuttings are used. Cutting short strips: (1-24 inches/2.5-61 cm) specialized devices are used.

Tiny scale cuttings: (42–49 inches/1071–125 cm) die cuttings are used. Broadsheet cutting: (e.g. 100 inches) Guillotine cutting is used. Laminate is the second level of finishing. The fiberboard is being sent among two rolls of paper. The adhesives are subjected to two rolls.

As a result, the fiberboard is coated with adhesive. Vinyl, foil, etc. are being used in the last covering. They are fitted with a lamination system.

MDF Board Vs Particle Board

Here we are discussing much differences between MDF Board Vs Particle Board are as follows.

1. MDF Board Vs Particle Board: Look

MDF Board: MDF has a smooth finish as it consists of wood grains that are of the same size.

Particle Board: Particle-boards do not have a smooth surface as they consist of wood shavings and chips.

2. MDF Board Vs Particle Board: Density

MDF Board: MDF has a higher density level than particle-board.

Particle Board:Particle-boards have a lesser density level.

3. MDF Board Vs Particle Board: Strength

MDF Board: Medium Density Fiberboard is fairly tougher than the particle-board.

Particle Board: Particle-board is not very tougher than the Medium Density Fiberboard.

4. MDF Board Vs Particle Board: Durability

MDF Board: Medium Density Fiberboard is very durable compare to the particle-board.

Particle Board: Particle-boards are fairly less durable.

5. MDF Board Vs Particle Board: Weight

MDF Board: Medium Density Fiberboard is Heavier than particle boards.

Particle Board: Particle-board is in Lightweight compare to the Medium Density Fiberboard.

6. MDF Board Vs Particle Board: Moisture

MDF Board: Medium Density Fiberboard is more resistance to water.

Particle Board: Particle-board is limited resistance to water.

7. MDF Board Vs Particle Board: Lifespan

MDF Board: Medium Density Fiberboardcan stay in a proper situation for up to 10 years.

Particle Board: Particle-boards can remain for up to 25 years.

8. MDF Board Vs Particle Board: Price

MDF Board: Medium Density Fiberboard is Costlier than the particle-board.

Particle Board: Particle-board is Cheaper in the price.

What Is MDF?

Medium-density fibreboard is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally more dense than plywood.

What Are the Advantages of MDF?

- MDF Is Hard to Both Flex or Crack: Although mdf is technically made out of wood, its structure is absolutely different. If you try to bend a mdf board it would rather snatch then warp. This is why engineered wood has the advantage of being resilient to moisture unlike its opponent. Of course, if you sink it in water, sooner or later the board will succumb to damage. But if you expose it to airborne moisture, the piece will expand and shrink as a whole while keeping the overall integrity and shape intact.

- MDF Is More Affordable and Easier to Supply: Generally, mdf boards come at a lower price than natural wood. Of course, there are a few exceptions if you compared high-end mdf with some of the less pricey types of timber. Another great benefit of engineered wood is the fact that you can find it easier than i.e. Maple or white oak, especially if you’re in need of a particular size.

- Mdf Is Easier to Paint and Seal: Contrary to solid timber, engineered wood lacks any specific grain or texture. This means that it’s easier to sand and prime without having to worry about looks or at worst – knots.

- MDF Is Best for Cabinetry: The advantages of engineered wood for cabinet doors are undisputable. The flexibility of manufacturing has offered interior designers to choose between flat-paneled, partially, fully overlay, inset, euro-styled and raised designs. Many types of mdf offer extra resistance to moisture, which is crucial for kitchen and bathroom furnishing.

Disadvantages of MDF

- MDF is comparatively weaker than wood. Furniture made up of MDF don’t last long. Though MDF is cheap, it, on the other hand, is a loss of money.

- MDF can crack or split under extreme stress.

- MDF absorbs water quicker than wood. So MDF may swell and everyone has to become conscious of using MDF.

- MDF doesn’t take nails and screws easily. During nailing, the fraction may appear around it. Pilot holes should be used while screwing.

Application of MDF Board

- Furniture.

- Cabinets and shelves.

- Flooring.

- Decorative projects.

- Speaker boxes.

- Wainscoting.

- Doors and door frames.

- Tradeshow booths and theater set construction.

What Is Medium Density Fibreboard Used for?

Medium density fiberboard, or MDF, is a manufactured product composed of wood fibers mixed with resin and wax, and pressed into flat panels under high temperatures and pressure. It is used as a building material in residential and commercial buildings.

MDF Properties

Several Medium Density Fiberboard (MDF) qualities make it an excellent replacement for plywood or particle-board. The property is dense, flat, stiff, remembers no knots, and is easily machined. It contains fine particles and gives dimensional stability without a predominant grain as is the possibility with wood.

MDF Sheets

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is generally denser than plywood.

MDF Board Thickness

MDF (Medium Density Fiberboard), available in thicknesses from 1/4” to 1-1/8”, is painted, printed or laminated, machined or fabricated into components of your choice. MDF is stronger and provides a better surface finish than particleboard (PB).

| Finish Type | Plain and Laminated |

|---|---|

| Board Material | Medium Density Fibreboard |

| Size of MDF | Standard Size: 8ft x 4ft (2440mm x 1220mm) |

| Density of MDF | 600-900 Kg/m3 |

| Thickness of MDF | 3.0 mm, 3.4 mm, 5.5 mm, 7.5 mm, 8.0 mm, 11.0 mm, 12.0 mm, 16.0 mm, 16.75 mm, 17.0 mm, 18.0 mm, 25.0 mm, 30.0 mm, 35.0 mm |

| Brand of MDF | GreenPly , CenturyPly , Action Tesa |

How to Waterproof MDF?

The only way to make the MDF board waterproof is to paint it. Painting the surface of the MDF board will make it resistant to moisture only if you use moisture-resistant paint, as this type of paint creates a more permanent waterproof layer on the MDF.

What Is MDF Made of?

MDF is traditionally made of wood fibers that have been broken down into residuals, then mixed with wax and resins and heat pressed into dense, durable sheets. A sheet of MDF will be heavy, smooth and even, with a flat surface that can be painted or sealed.

What Is MDF Board?

MDF is a high grade, composite material. It is made from recycled wood fibers and resin. It is dried and pressed to produce dense, stable sheets. Because of this process, MDF does not warp or crack like wood. And since MDF is made from small particles, it doesn’t have noticeable grain patterns.

MDF Vs Particle Board

MDF has a smooth finish as it consists of wood grains that are of the same size. Particle–boards do not have a smooth surface as they consist of wood shavings and chips. MDF has a higher density level than particle–board. Particle–boards have a lesser density level.

What Does MDF Stand for?

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally more dense than plywood.

What Is MDF Paneling?

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. It is stronger, and more dense, than particle board.

Can You Paint MDF Board?

You can use your preferred paint on primed MDF, and you can apply the paint finish with your preferred applicator, be it a brush, roller, or spray gun—whichever best suits the project. Once the first coat of paint feels dry to the touch, assess if your work needs a second coat.

What Are the Disadvantages of Using MDF?

- MDF is comparatively weaker than wood. Furniture made up of MDF don’t last long. Though MDF is cheap, it, on the other hand, is a loss of money.

- MDF can crack or split under extreme stress.

- MDF absorbs water quicker than wood. So MDF may swell and everyone has to become conscious of using MDF.

- MDF doesn’t take nails and screws easily. During nailing, the fraction may appear around it. Pilot holes should be used while screwing.

- MDF contains VOC, containing urea formaldehyde, that can cause irritation to lungs and eyes.

- Dust produced during the manufacture of MDF is very harmful to breathing.

Why Is MDF Banned in the USA?

In 1994, rumours circulated in the British timber industry that MDF was about to be banned in the United States and Australia because of formaldehyde emissions. The US reduced its safety exposure limit to 0.3 parts per million – seven times lower than the British limit.

Is MDF Better Than Plywood?

MDF is ideal for cutting, machining and drilling, since it does not chip easily. On the other hand, plywood is a much more stronger material, which can be used for doors, floors, staircases and outdoor furniture. It is easier to create curved surfaces with plywood, since it bends easily.

Is Plywood Safer Than MDF?

Though plywood is more water resistant than MDF, it is still porous and susceptible to damage when exposed to water over time.

What Is Better for Cabinets MDF or Plywood?

In the right application, MDF can actually be better than plywood or solid lumber. MDF has great strength, does not noticeably shrink or expand with temperature, and has a uniform surface without grain or knots. It is also less expensive than plywood.

Is MDF Stronger Than Plywood?

MDF is ideal for cutting, machining and drilling, since it does not chip easily. On the other hand, plywood is a much more stronger material, which can be used for doors, floors, staircases and outdoor furniture.

Is MDF Safe?

The main concern regarding the health risks of MDF is the use of urea-formaldehyde adhesives as the bonding agent during the creation of the panels. Formaldehyde has been thought to have cancer risks. While MDF dust can cause nose and eye irritation, this is also true for every other dust.

Medium Density Fiberboard Weight

| Material | Panel Weights Size 2.6 mm thick |

| Medium Density Fiberboard (Langboard, Holly Hill, Plum Creek, Uniboard, etc.) | 1.10 Sq.ft |

| Particle Board | 1.15 Sq.ft |

| Domestic Hardwood MDF and MDF Core Melamine | 1.15 Sq.ft |

What Is MDF Used for?

MDF is primarily used for indoor applications due to its poor moisture resistance. It is available in raw form, or with a finely sanded surface, or with a decorative overlay. MDF is also usable for furniture such as cabinets, because of its strong surface.

How to Cut Fiberboard?

Once you have a line drawn, take a utility or Stanley knife and run the knife along the cut line using minimal pressure at a steady to slow speed. Do this until you successfully cut through the laminated surface.

How to Cut MDF Board?

Any circular saw or handheld cutting tool will make rip cuts or crosscuts in MDF, but the blade should be carbide-tipped, because the high glue content of the material dulls steel blades quickly.

What Is Medium Density Fiberboard?

Medium-density fibreboard is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally more dense than plywood.

Is MDF Particle Board?

Medium Density Fiberboard (MDF) is an engineered wood composite that is similar to particle board, but is much denser and stronger than particle board. Because it’s composed of such small wood fibers, there’s no wood grain in MDF.

Types of MDF Wood

There are three different types of MDF: particle board, fiber board, and laminated board. MDF, or Medium Density Fiberboard, is used for many different building projects and sold at most hardware stores.

Is MDF Safe When Painted?

In short, yes, it is 100% safe once it is used to construct a finished piece of furniture, but it does require care if you decide to do a DIY project with MDF where there will be sawdust flying about.

What Is Medium Density Fibreboard Used for?

Medium density fiberboard, or MDF, is a manufactured product composed of wood fibers mixed with resin and wax, and pressed into flat panels under high temperatures and pressure. It is used as a building material in residential and commercial buildings.

What Are the Grades of MDF?

Most MDF can be broken down into three categories: The Lightweight MDF, Standard Grade MDF & the High Density MDF. Standard grade MDF is made up of wood fibres with a synthetic resin adhesive to form the board.

Is Medium Density Fiberboard Good?

Not Strong and Durable. Unlike solid wood or plywood furniture, MDF furniture is not very strong and durable but is resistant to termites. It has to be handled with care. In case it gets damaged, it is difficult to repair it.

Is HDF Better Than MDF?

It is a stronger, harder product than MDF with a typical density of up to 900kg/m3. HDF is predominantly used in laminate flooring products where this density is required, though other uses include door skins and underlayment. Most likely it will be a dense grade of MDF being sold under the wrong name.

What Is High Grade MDF?

MDF is a high grade, composite material. It is made from recycled wood fibers and resin. It is dried and pressed to produce dense, stable sheets. Because of this process, MDF does not warp or crack like wood. And since MDF is made from small particles, it doesn’t have noticeable grain patterns.

Is MDF Board Easy to Cut?

A jigsaw cuts MDF as easily as it cuts plywood, although you should keep in mind that the more teeth the blade has, the less chance there is of chipping the material around the edges of the cut. You can also cut curves in MDF with a handheld multipurpose or rotary tool fitted with a multi-purpose cutting blade.

Is Cutting MDF Board Dangerous?

It is the way MDF is made that gives it these qualities – and makes it potentially dangerous. When MDF is cut, sanded, shaped or machined in any way, it releases clouds of dust particles coated with formaldehyde.

Like this post? Share it with your friends!

Suggested Read –

- Flying Staircases

- Double Pitch Roof

- What Is Dressing of Stone | Types of Dressing of Stone

- Floating Slab Vs Monolithic Slab | What Is Monolithic Slab | What Is Floating Slab

- RCCFull Form | What Is RCC | Advantages & Disadvantages of Reinforced Cement Concrete | Properties of RCC | What Does RCC Stands for

- What Is a Cavity Wall | How to Build a Cavity Wall | Cavity Wall Detail | Cavity Wall Thickness | Cavity Wall Insulation Pros and Cons | Brick Cavity Wall

- What Is Oblique Drawing | Oblique Drawing Examples | What Is Oblique View | Oblique Projection | Oblique Shape | Cabinet Oblique | What Is Cavalier Drawing

- Which of the Following Is a Way That Slopes Fail | Types of Slope Failure | Geotechnical Failures | Types of Slopes in Geography | Causes of Slope Failure | Slope Stability

- What Is Pier and Beam Foundation | Advantages & Disadvantage of Pier and Beam Foundations | Pier and Beam Foundation Design | How to Build a Post and Pier Foundation

Leave a Reply