What Is Micropile?

Important Point

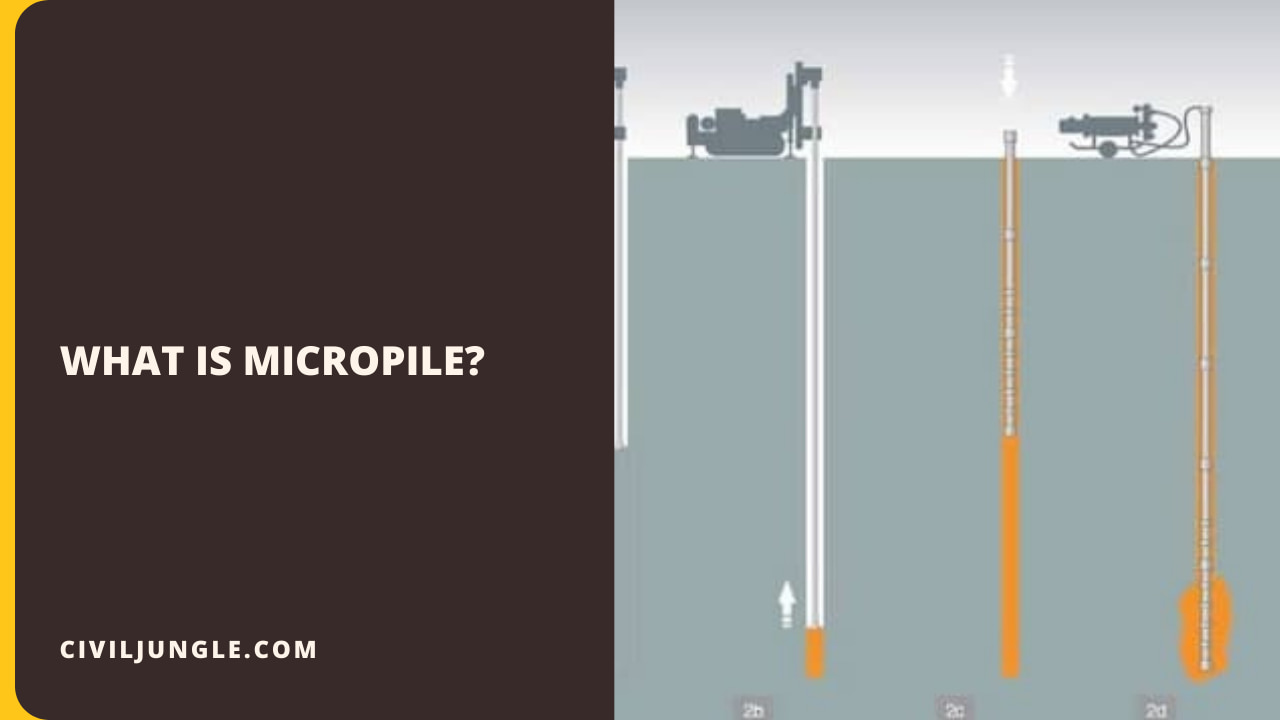

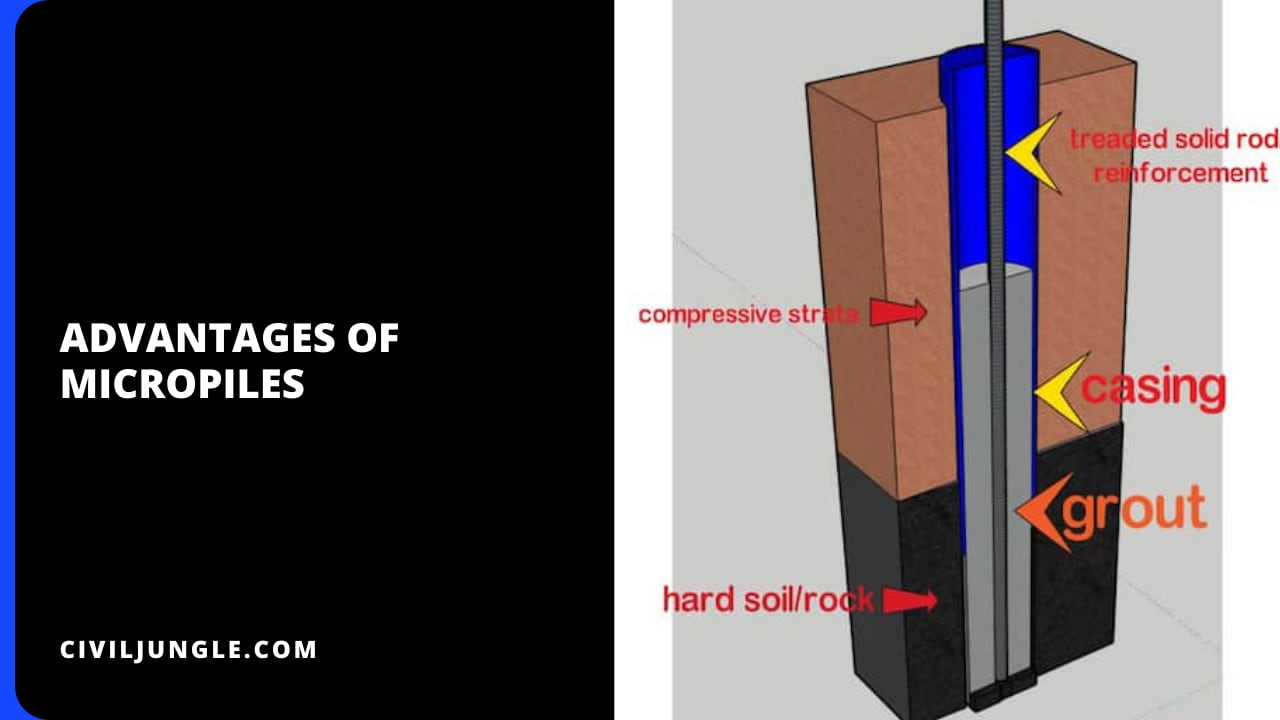

- Micro-piles/ mini-piles/ pin-piles/ root-piles are high-strength, durable, small-diameter generally 6-12”(150-300mm) steel casing pile or rib or bar and stuffed with a high strength cement grout used to bore hole.

- The bearing stratum is logged throughout installation drilling to assure that bearing capability is adequate.

- Since small piles are smaller in diameter they will be advanced through the bottom at a better speed and may break through materials with larger ease than a caisson casing or a driven pile.

- The micropiles will penetrate any obstructions which will typically cause premature refusal whereas putting in mistreatment typical spile strategies.

- Grouting is achieved by tremie grouting, pressure grouting throughout casing retraction, and tremie-grouting with post-grouting. Post-grouting among the bond length will increase resistance forces with close soils, so achieving larger capability.

- Micropile capacities in way over four hundred kips (1,780 KN).

- Micropiles to depths surpassing two hundred feet (60 m).

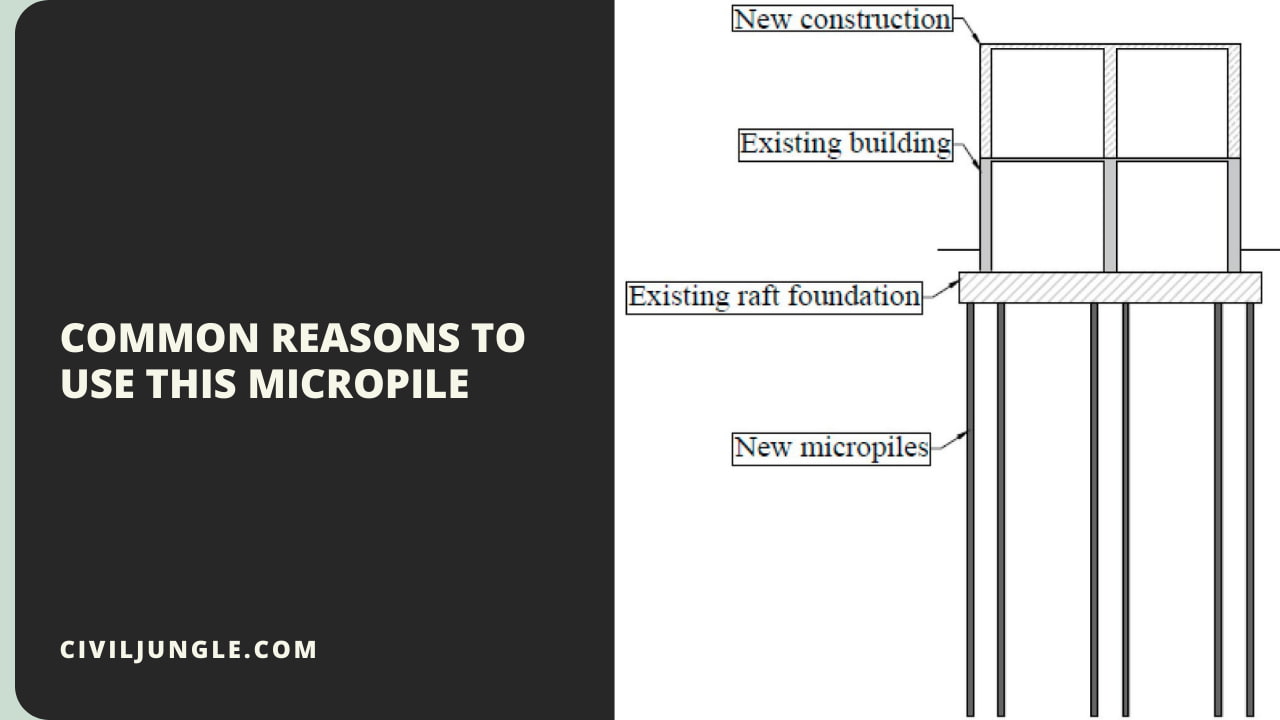

Common Reasons to Use This Micropile

- To give structural support

- To underpin your foundation

- To transfer hundreds

- To enhance mass stability

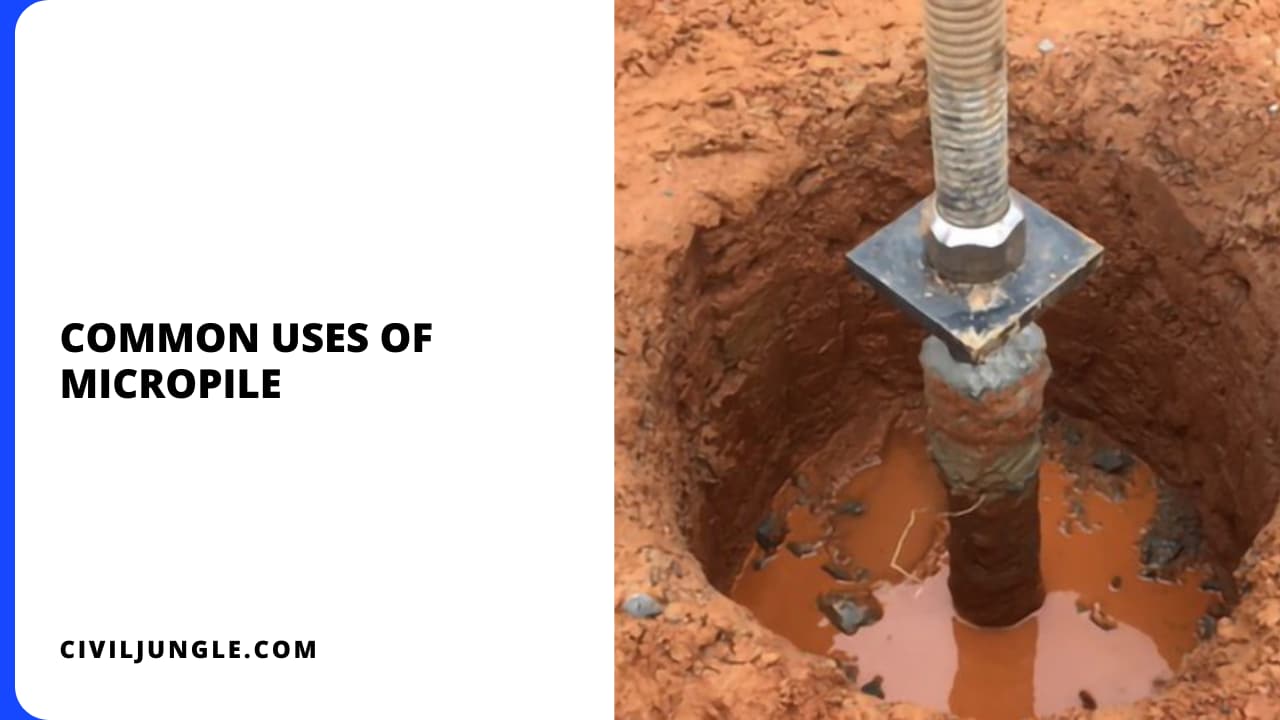

Common Uses of Micropile

- Provide structural support

- Underpin foundations

- Enhance mass stability

- Transfer loads

Advantages of Micropiles:

- The main advantage of a micropile is its ability to figure in terribly engorged and low height areas and on any soil surface regardless of its sort.

- Fast ballroom dancing installation even in environmentally-challenging conditions. They’re little and comparatively lightweight. they’re comparatively cheap.

- Simultaneous drilling and grouting allow low overhead, restricted access installation. Micropiles are typically preferred to “H” piles attributable to overhead physical constraints.

- Improves the bottom (densification)

- Offers higher skin friction

- Total single corrosion protection intentionally

- The restricted vibration and noise cause very little disturbance.

- Piling rigs may be low-emission or perhaps electrically driven.

- They can be put in on the point of existing walls with restricted headroom and engorged website conditions.

- They have a high load capability and a capability to resist compressive, tensile, and lateral masses.

- Micro-piles can penetrate any surface.

Also, Read: Piling for Foundation | Use of Pile Foundation | Characteristics of Pile Foundation

Useful Article for You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is Mdf Mean

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is SuperelevationWhat Is Overhang

- What Is Sand Blasting

- What Is a Span Bridge

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- Different Types of Beam

- What Is Plumbing Fixtures

- What Is Calacatta Quartz

- What Is Auxiliary View

- Sheepsfoot Roller

- Live Load Vs Dead Load

- Footing Vs Pier

- What Is 1 Flight of Stairs

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- Arch Foundation

- What Is a Stair Landing

- What Is Stone Masonry

- What Is a Spandrel Beam

- What Is a Pile Cap

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is Modulus of Rupture

- What Is a Flush Door

- What Is Residential Construction

- What Is Oblique Drawing

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is a Monolithic Slab Foundation

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is a Tremie

- What Is Tributary Area

- What Is Shoring Construction

- What Is a Cason

- What Is Wall Putty

- What Is the Difference Between Mortar and Concrete

- What Is Bhk

- What Is Sbc of Soil

- What Is Plinth Level

- What Is Water Proofing

- What Is Mix Design of Concrete

- What Is Fine Aggregate

- What Is Retention Money

- What Is Design Mix

- What Is Isometric Scale

- What Is a Half Wall Called

Disadvantages of Micropiles:

- If there aren’t any obstacles they’re longer overwhelming than a driven pile

- Valuable

- Water infill is often a problem

Micropile Vs Typical Pile:

- Micropiles are engaged in any difficult conditions involving soil and rock.

- Micropiles are custom and applied for tough terrains and applications.

- Micropiles are used for rehabilitation.

- Micropiles penetrate any surface and might be put in even though an existing foundation creating it one of the simplest doable solutions for foundation rehabilitation and strengthening works.

- Small piles are used for slope stabilization, hill stabilization, and different soil improvement and any kind of ground improvement works.

- Micro piles are employed in areas wherever geological formation is high, urban backfills, areas having floating boulders or different tough terrains that can’t even be accessed with a traditional pile.

- Used extensively within the rehabilitation of monuments, recent structures, sinking structures, etc altogether components of the globe.

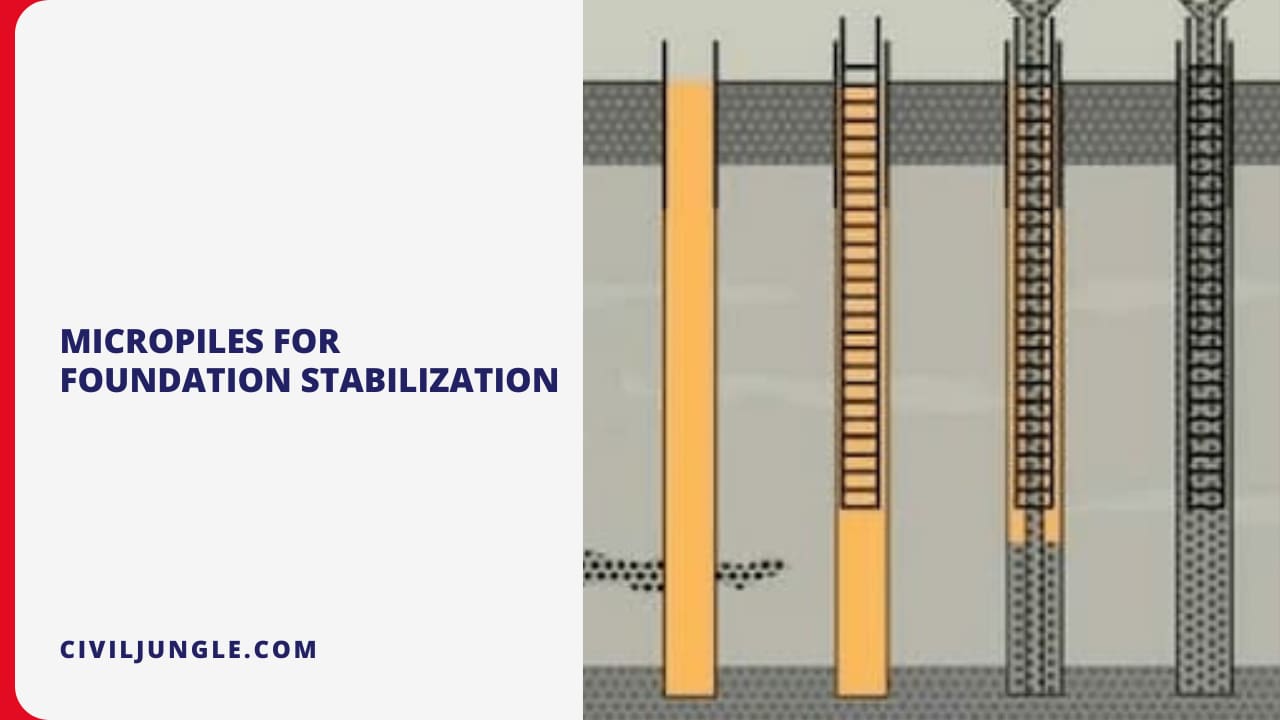

Micropiles for Foundation Stabilization:

Certain soil conditions will obstruct installation and even thwart the advancement of conventional underpinning solutions. When such conditions exist, trained and grouted micropiles provide an economical, deep foundation possibility capable of penetrating obstructions connected among competent bedrock.

- In compression applications, capability is achieved through finish bearing and conjointly skin friction on the interface of the grout column and therefore the bedrock.

- In tension applications, solely the skin friction contributes to the micropile capability.

Drilling Ways Adopted for Small Piles:

The foremost common ways adopted for drilling are:

- Percussive Drilling used with a driving point/drill at an all-time low of the permanent casing is outlined as displacement technique whereas once the air is employed as a flushing medium. It is outlined as a non-displacement technique.

- Rotary drilling uses air or water as a flushing medium for removing the trained materials from the excavation. The air jet or water pumped up through the drilling system exit at the drilling bit finish flushing out the cuttings.

What Are the Everyday Applications for a Micropile?

- Micro-pile systems are most popular to support and stabilize buildings, bridges, highways, towers and alternative unreal structures, either as new foundations or remedial construction.

- Morever, they are used for underpinning and shoring applications because of their high load capability and versatile installation techniques.

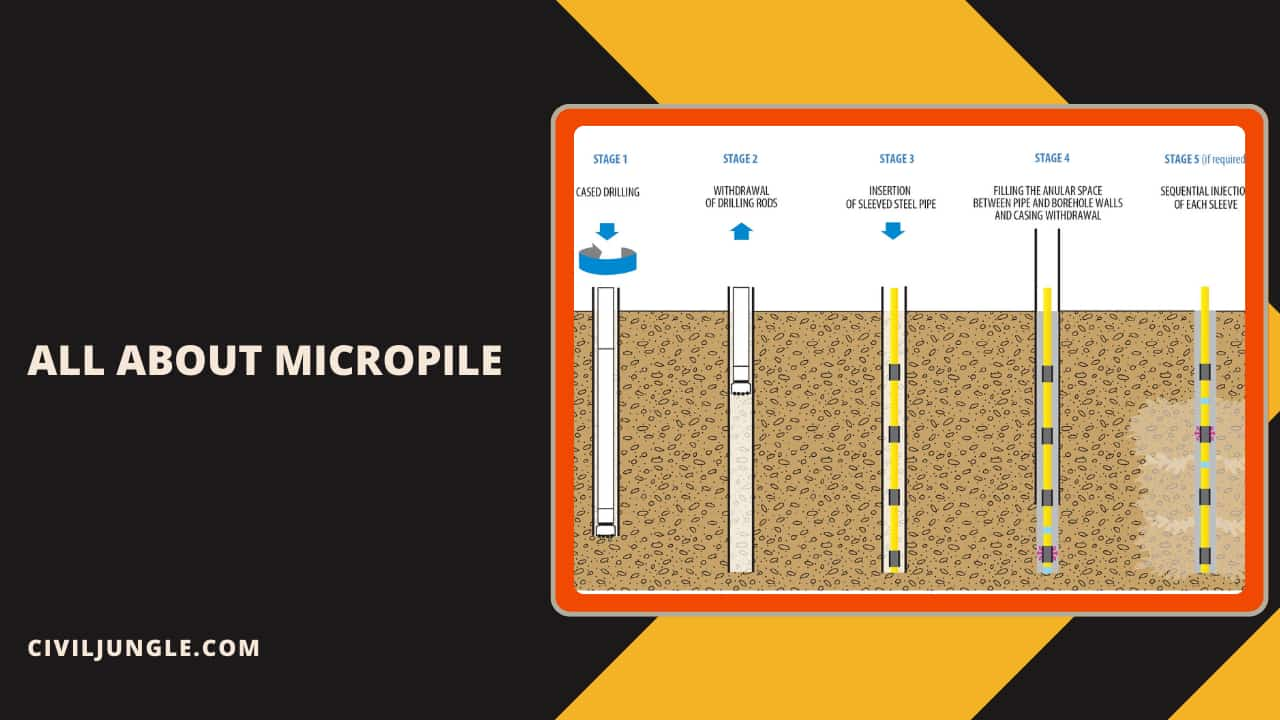

How Will the Micropile Installation Method Work?

- The first and foremost affair anyone would like to attempt, is to dig a cavernous hole with a tiny diameter.

- Once, house has been secured for the pile, lower that into the outlet and apply force to secure the pile.

- Then fill the outlet with a concrete grout concoction to keep everything in situ.

Useful Article for You

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Cmu Wall Meaning

- Gradient Road

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- Well Points

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

- How Heavy Is Dirt

- Tender Meaning in Architecture

- Dark Olive Green House

- Cast in Place Concrete

- Lean to Roof

- How Tall Is an Average Door

- Window Sill Height

- Concrete Cold Joint

- Types of Traps

- Types of Pipe

- Wood Supporting Beams

- Finishing Plaster

- Home Depot Scrap Wood

- Lvl Beam Size Calculator

- Structural Shell

- Curb Types

- Msand

- Optimum Dry Meaning

- Disadvantages of Low-E Glass

- Bridge Abutment Definition

- Build Materials List

- Composite Masonry Wall

- Is Cedar a Hardwood or Softwood

- Modified Proctor Test

- Physical Properties of Sand

- Sugar in Concrete

- Crane Machine Construction

- Types of Gable Roofs

- Door Frame Types

- How Much Does 55 Gallons of Oil Weigh

- Dog Leg Stairs

- Concrete Salt Finish

- Westpoint Bridge Builders

- Types of Porches

- Hempcrete Disadvantages

- Roof Pitch Types

- Types of Weirs

- Asphalt Floor

- Dutch Roof

- #6 Rebar Weight Per Foot

- Prizmatic Compass

- Bond Break Concrete

- Poured Concrete Wall Cost Calculator

- How Many 60 Lb Bags of Concrete in a Yard

- Wood Fence Post Spacing Chart

- Falsework

- Design of Building Structures

- Topping Slab

- Types of Cinder Blocks

- Fresh Concrete

- Door Colors for Red Brick House

- Foundation Spalling

- Clear Cover Concrete

- Tiles Brand

- Cement Consumption in Plaster

- Aggregate Density Kg M3

- Load Bearing Wall Construction

- Weight of Concrete Slab Calculator

- Cyclonic Precipitation

- Curtain Names

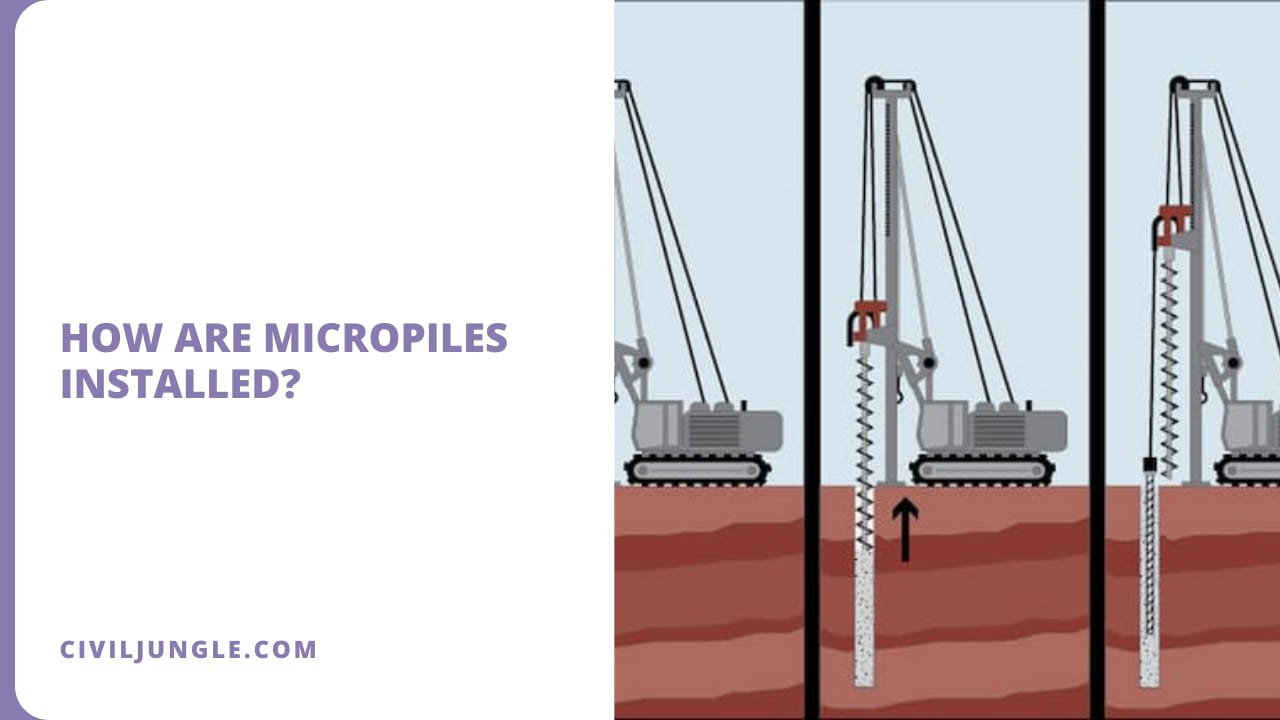

How Are Micropiles Installed?

- Drilled into bedrock, micro-piles are bond to the rock socket wall for conveying a load.

- The casings of the minipiles are advanced as piles are trained into bedrock.

- Drill rod is withdrawn and the steel casing remains. On reaching the saturation level the drilling bit is withdrawn with casing left within the bore-hole.

- A reinforcement load bar is lowered into the casing. Assign reinforcement with centralizer within the borehole, along with tremie grout & cement water blend.

- Cementitious grout along with pressure is fed into the minipile casing and rock socket. After Tremie grouting, perform a pressure grouting through preinstalled grouting tubes.

- The casings for the mini piles are heaved up to a high of bedrock, which permits bonding to the bar.

- Excess steel is cut from the superior of minipiles.

Also, Read: Grillage Foundation | Types of Grillage Foundation | Features of Grillage Foundation

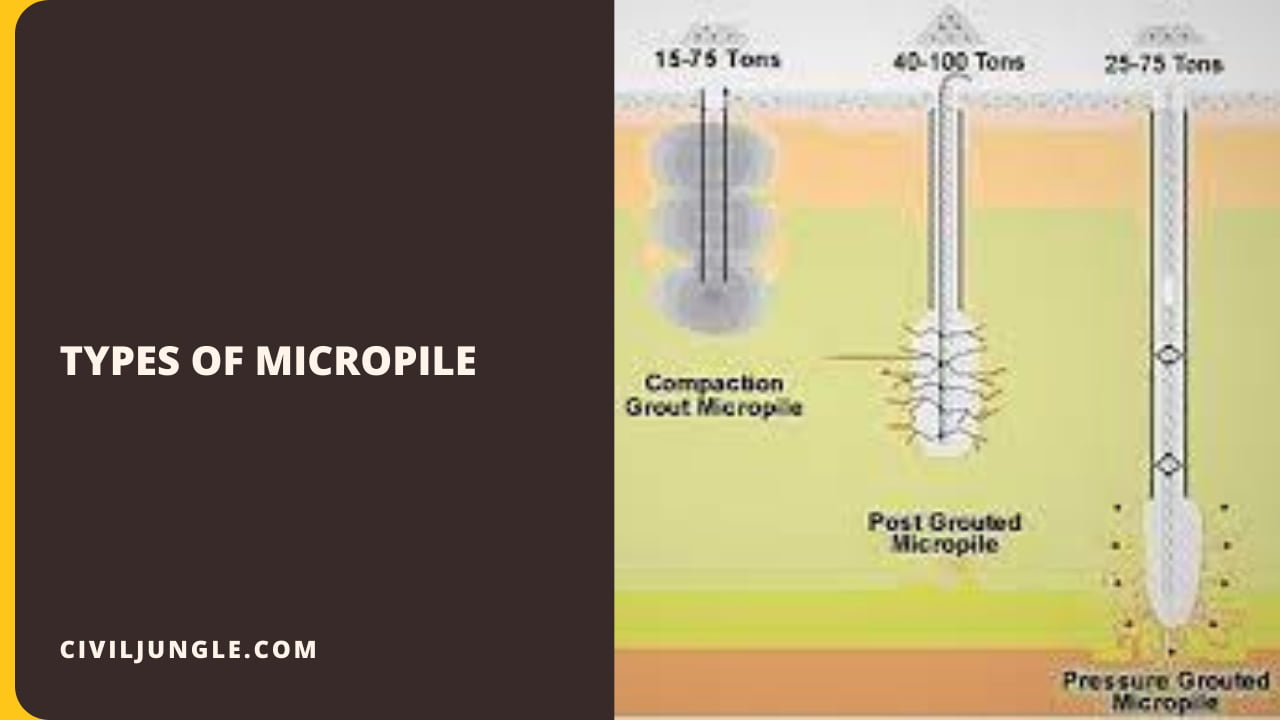

Types of Micropile:

Piles are generally categorized into 2 types:-

- Displacement Piles

- Replacement Piles

#1. Displacement Piles

- Displacement piles are driven or vibrated into the bottom, there by displacing the adjacent soil sideways during the inauguration.

#2. Replacement Piles

- Replacement piles are constructed within a formerly drilled borehole, thus restoring the excavated ground.

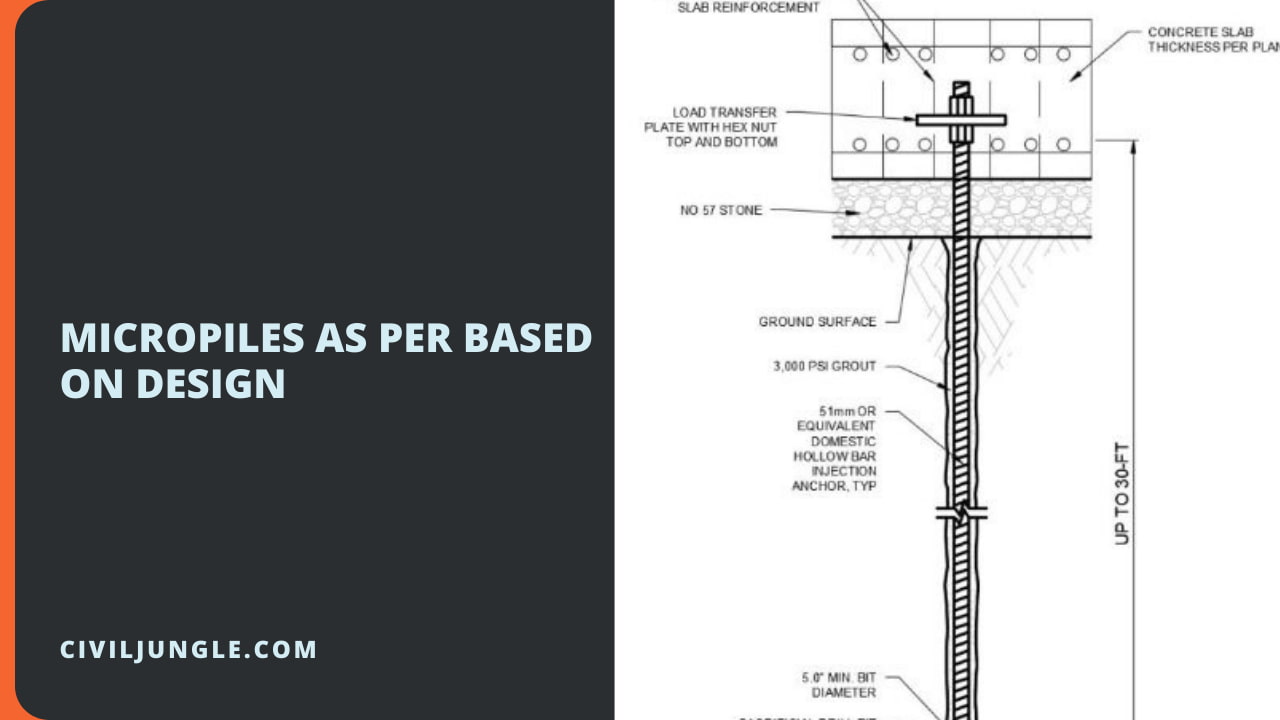

Micropiles as Per Based on Design:

Based on Design Application mini piles are categorized into 2 cases:-

Case 1:

- Micro-pile elements, which are stuffed directly & where the pile reinforcement withstands the bulk of the applied load.

Case 2:

- Micro-pile elements circumscribe and internally reinforce the soil to create a reinforced soil composite that withstands the applied load.

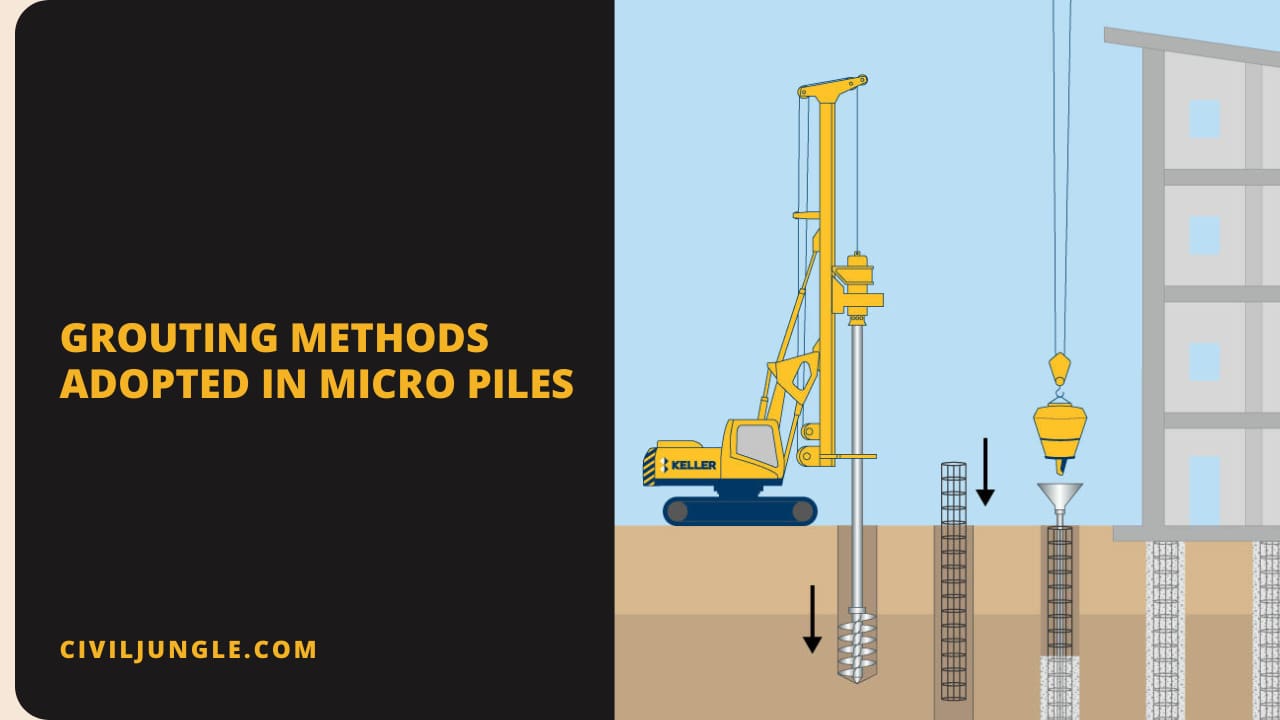

Grouting Methods Adopted in Micro Piles:

Grouts utilized for micro-piling comprise a blend of sand, cement, and water. The micro piles are categorized into 4 types based on the stratagem of grouting.

Type A Micropiles: Gravity Grout:

- They use tremie grouting and through gravity head.

- The grouting is started from the substratum and follows an identical tremie grouting procedure followed in conventional piles.

Type B Micropiles: Pressure Through Casing:

- After performing the initial tremie grouting, pressure grouting is finished concomitantly with the lifting of the casing from the bond zone through a pre-installed tube.

- 2nd stage of grouting serves in amplifying grout soil bonding.

- Neat cement grout is placed in to the cavity as the provisional steel casing is withdrawn.

- Injection pressures range from 0.5 to 1.0 MPa.

Type C Micropiles: Single Global Post Grout:

- Pressure grouting is followed by tremie grouting.

- Then, a global injection grouting is performed through a pre-installed sleeve port pipe.

- Before hardening of the primary grout, similar grout is injected once via a sleeve grout pipe at a pressure of a nadir of 1.0MPa.

Type D Micropiles: Multiple Repeatable Post Grout:

- This method is a twin of Type C.

- Primary grout is done under pressure and after coagulation, secondary grout is finished through installed sleeve ports.

Micropiles Cost

| Detail | Amount |

| Micro Piles | $1,026,000 |

| F/R/P Pile Caps | $39,039.56 |

| F/R/P Grade Beams and Piers | $75,354.92 |

| F/R/P Foundation Walls | $18,583.76 |

| Concrete ‐ 3000 psi | $81,456 |

| Total Value | $1,240,434 |

Micropiles Cost

Micro Piles cost about $120 per linear foot, which is more expensive than the original H-piles. Changing the foundation system to Micro Piles will cost an additional $120,435. However, the Micro Piles also reduce the schedule by 24 days and allows the building to be rented sooner.

What Is Micropile

Micropiles, also known as minipiles, pin piles, needle piles, and root pile, is a deep foundation element constructed using high-strength, small-diameter steel casing and/or threaded bars.

Common Uses of Micropiles

Micropiles are generally used when there are difficult ground conditions, such as natural or man-made obstructions, sensitive ground with adjacent structures, limited access/low headroom and/or karstic geology.

Advantages of Micropiles

- High load capacity in both tension and compression.

- Easily socketed into hard rock and can penetrate through subsurface obstructions and/or boulders encountered during installation.

- Minimal vibration and disturbance to adjacent structures in close proximity during installation.

Disadvantages of Micropiles

The only disadvantage of micropiles is the relatively high cost as compared to other piling systems except for the case of shallow pile termination depth. Micropiles are generally classified firstly according to design application and grouting method.

Micropile Vs Typical Pile

A foundation is described as piled when its depth is more than three times its breadth. Micropiles are piles that have a relatively small diameter, typically in the range of 100-250 mm. They can also be described as Minipiles (generally mini piles are smaller than micro piles)

How Are Micropiles Installed

The micropile casing generally has a diameter in the range of 3 to 10 inches. Typically, the casing is advanced to the design depth using a drilling technique. Reinforcing steel, typically an all-thread bar is inserted into the micropile casing. High-strength cement grout is then pumped into the casing.

Like this post? Share it with your friends!

Suggested Read –

- Masonry Vs Brick

- Difference Between Tied Column and Spiral Column | What Is Spiral Column | What Is Tied Column

- What Is Soil Vent Pipe | How Does Soil Stack Pipe Works | Soil Vent Pipe Material | Types of Plumbing System

- What Is Tie Beam | Tie Beam Details | Advantages of Using Tie Beam | Tie Beam Reinforcement | Why Are Use Concrete Tie Beam

- Emulsion Paint Vs Oil Based Paint | Purpose of Providing Paints | Properties of Good Paint | Properties of Good Paint | What Is Oil Based Paint

- What Are Weep Holes | Need for Weep Holes | Foundation Weep Holes | Types of Weep Holes | Weep Holes In Retaining Wall | Window Weep Holes

- What Is False Ceiling | Why We Need False Ceiling | Types in False Ceilings | Advantages & Disadvantage of False Ceiling | False Ceiling Installation Steps by Step

- What Are Plastic Roads | How to Make Plastic Roads | Who Invented Plastic Roads | First Man-Made Plastic Road | Advantages & Disadvantages of Plastic Roads

Leave a Reply