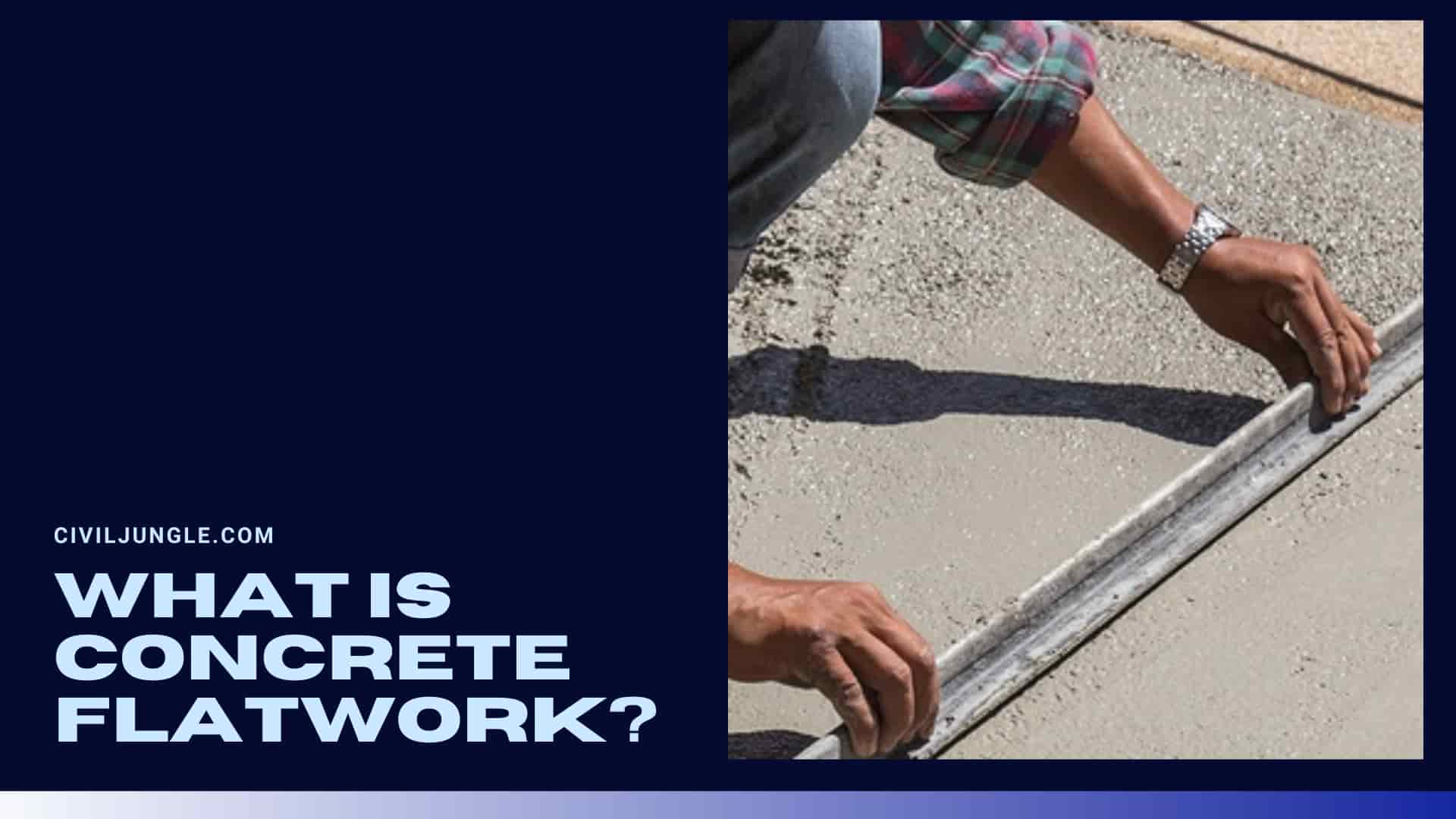

What Is Concrete Flatwork?

Important Point

Concrete flatwork refers to the process of constructing flat surfaces made of concrete, such as driveways, sidewalks, patios, and flooring for commercial or residential buildings.

The term “flatwork” refers to the horizontal surfaces of concrete as opposed to vertical structures like walls or pillars.

The process of constructing concrete flatwork involves several steps including preparing the site, pouring the concrete mixture, and finishing the surface.

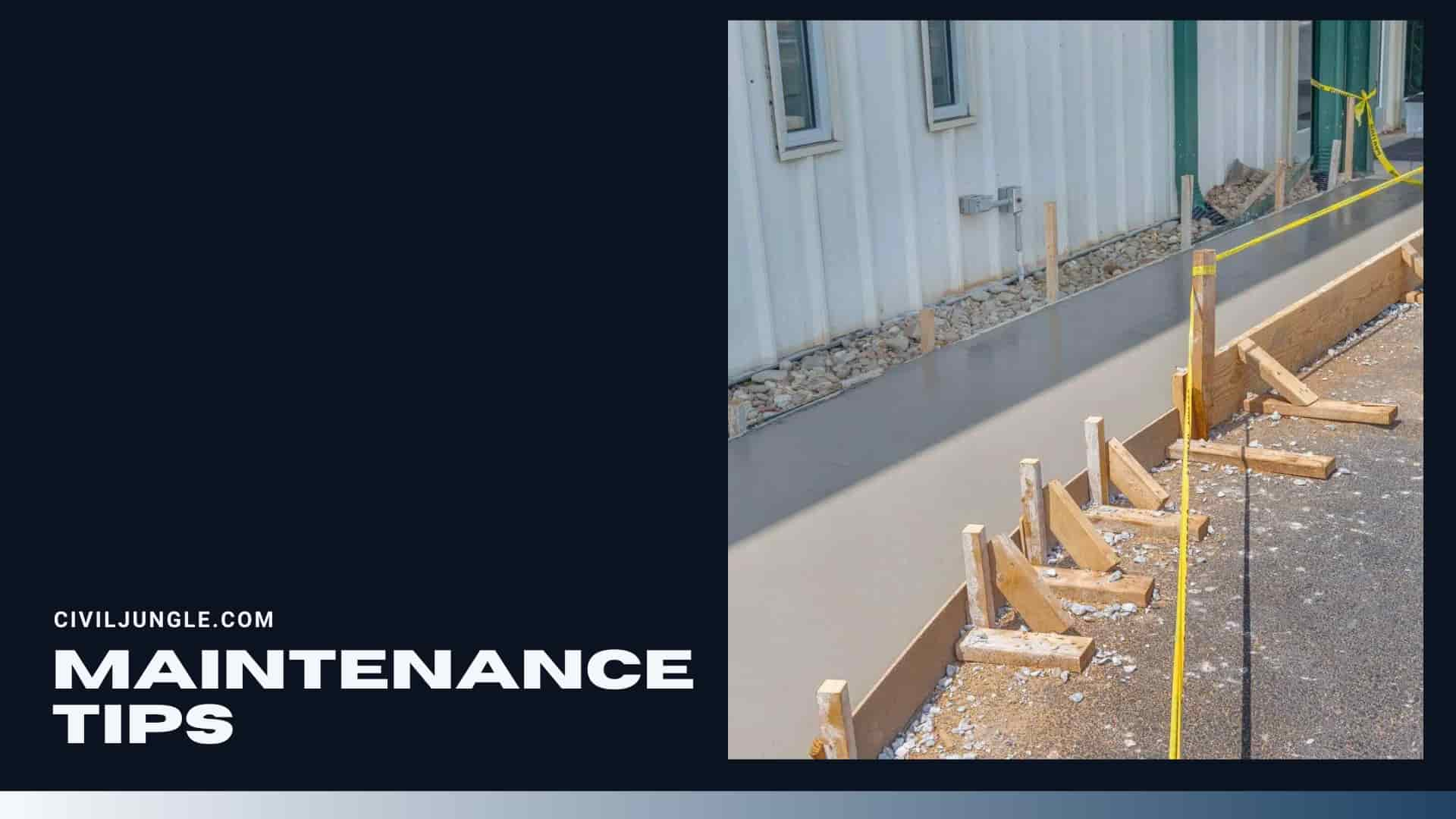

Preparation of the site involves digging the ground to a specific depth, installing forms to contain the concrete mixture, and ensuring proper grading and drainage to avoid any settling or cracking of the concrete after it has been poured.

Once the site is prepared, the concrete mixture is made by mixing Portland cement, sand, aggregate (such as gravel or crushed stone), and water in a specific proportion to create a mixture with the desired strength and consistency.

The mixture is then poured into the forms and leveled with a screed, which is a straight-edged board used to strike off the excess concrete to form a smooth surface.

After the concrete has been poured, it is smoothed using a trowel and allowed to cure for a minimum of 24 hours.

During the curing process, the concrete sets and hardens, and excess water evaporates, leaving behind a strong, durable surface.

Once the concrete has cured, the forms are removed, and the surface is cleaned and finished. Finishing techniques vary based on the intended use of the flatwork and can include power troweling, hand troweling, and stamping or scoring patterns into the surface to create a decorative finish.

There are several factors that influence the quality of concrete flatwork, including the type of concrete mixture used, the skill of the contractor, and the conditions under which the concrete is poured and cured.

For example, temperature, humidity, and wind can all affect the curing process, and if the conditions are not ideal, the concrete may not set properly or may develop cracks or weaknesses.

Another factor that affects the quality of concrete flatwork is foundation on which it is built.

The soil beneath the concrete must be compacted and stable to support weight of the concrete and prevent settling or cracking over time.

In addition, proper grading and drainage must be established to ensure that water does not pool on the surface, which can cause damage and erosion.

Concrete flatwork is a versatile and durable material that is used in a wide range of applications, from residential driveways and sidewalks to commercial flooring and patios.

The strength, durability, and versatility of concrete make it an ideal choice for many construction projects, and with proper care and maintenance, concrete flatwork can last for decades.

In conclusion, concrete flatwork refers to the process of constructing flat concrete surfaces and involves several steps, including site preparation, pouring the concrete mixture, and finishing surface.

The quality of concrete flatwork depends on several factors, including the type of concrete mixture used, the skill of the contractor, and the conditions under which the concrete is poured and cured. With proper care and maintenance, concrete flatwork can provide a strong and durable surface for many years to come.

Concrete Flatwork Design

Concrete flatwork design refers to the planning and execution of flat concrete surfaces, such as driveways, sidewalks, patios, and flooring, taking into consideration the intended use, aesthetic appeal, and long-term durability of the concrete.

A well-designed concrete flatwork can not only enhance the appearance of a property, but also provide a strong and durable surface that can last for decades with proper care and maintenance.

The first step in designing concrete flatwork is determining the intended use of the surface. This will help determine the thickness, strength, and finish of the concrete required for the project.

For example, a driveway will require a thicker and stronger concrete mixture than a sidewalk, and a commercial floor may require a more decorative finish than a residential patio.

Once the intended use of the surface has been determined, next step is to consider the aesthetic appeal of concrete.

This can include selecting a color or finish that complements the surrounding environment, adding decorative elements such as stamped patterns or scored lines, or incorporating concrete into the overall design of the property.

In addition to aesthetic appeal, the design of concrete flatwork must also take into consideration the long-term durability of the concrete.

This includes factors such as the type of concrete mixture used, the conditions under which the concrete is poured and cured, and the stability of the soil beneath the concrete.

One of the key factors that affects the durability of concrete flatwork is the type of concrete mixture used.

A concrete mixture that is too weak will not be able to withstand the weight and pressure placed on the surface, while a mixture that is too strong will be more prone to cracking.

The appropriate type of concrete mixture for a specific project can be determined by a professional concrete contractor based on the intended use of the surface and the conditions under which the concrete will be poured and cured.

Another factor that affects the durability of concrete flatwork is the conditions under which the concrete is poured and cured.

Temperature, humidity, and wind can all affect the curing process, and if the conditions are not ideal, the concrete may not set properly or may develop cracks or weaknesses over time.

The foundation on which concrete flatwork is built also plays a crucial role in its durability.

The soil beneath the concrete must be compacted and stable to support the weight of the concrete and prevent settling or cracking over time. In addition, proper grading and drainage must be established to ensure that water does not pool on the surface, which can cause damage and erosion.

In conclusion, concrete flatwork design involves taking into consideration the intended use, aesthetic appeal, and long-term durability of the concrete.

The design of concrete flatwork must balance the aesthetic appeal of the surface with the strength and durability required for the specific application.

Factors such as the type of concrete mixture used, the conditions under which the concrete is poured and cured, and the stability of the soil beneath the concrete all play a crucial role in the durability of concrete flatwork.

With proper design and execution, concrete flatwork can provide a strong and attractive surface that can last for decades.

Use Full Article For You

- Static Rollers

- Epoxy Flooring Cost Calculator

- Is Steel Stronger Than Concrete

- How to Calculate Dead Load

- Hemp Building Blocks

- Excavation Rates Per M3

- Hempcrete Vs Concrete

- How Is the Skeleton Similar to the Frame of a House?

- Queen Size Mattress in Feet

- Different Crane Types

- Zero Force Members Examples

- Quikrete Floor Mud

- How Many 60 Pound Bags of Concrete in a Yard

- Name Types of Shovels

- How Long Does It Take for Mortar to Dry

- Two Flights of Stairs

- Contour Interval on a Topographic Map

- Material Properties of Plywood

- Advantages of T Beam

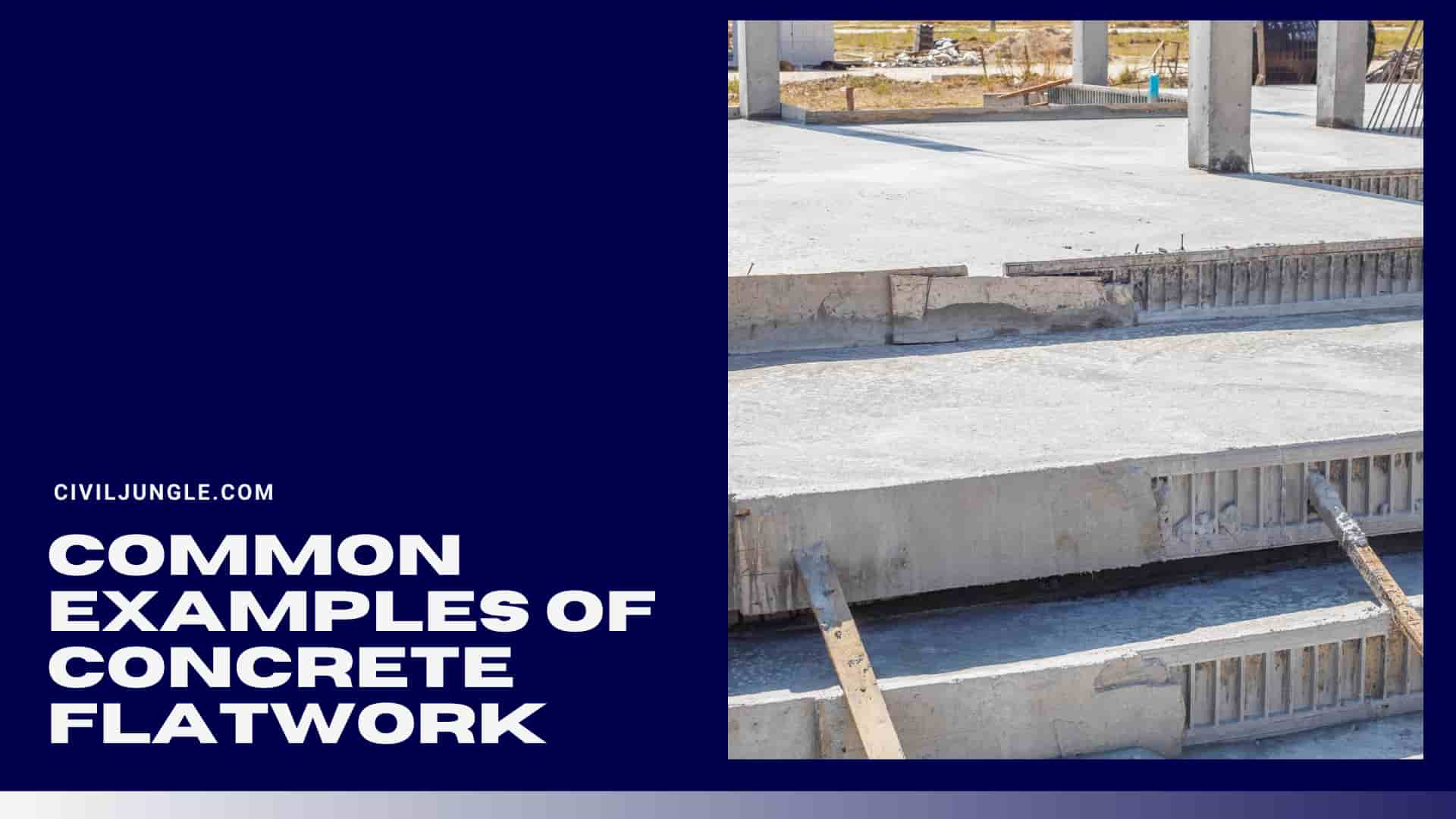

Common Examples Of Concrete Flatwork

Concrete flatwork refers to any flat concrete surface, including driveways, sidewalks, patios, and flooring. Here are some common examples of concrete flatwork:

-

- Driveways: Driveways are one of the most common examples of concrete flatwork. They are typically wider and thicker than sidewalks and must be able to withstand the weight of vehicles. Driveways can be designed to complement the overall appearance of a property, and can be finished with a variety of textures and colors to create an attractive and durable surface.

-

- Sidewalks: Sidewalks are typically narrower than driveways and are used for pedestrian traffic. They can be straight or curved, and can be designed to match the aesthetic of a property. In many cases, sidewalks are required by local building codes and must be accessible to people with disabilities.

- Patios: Patios are outdoor living spaces that are typically used for relaxing, entertaining, and outdoor dining. They can be designed to complement the overall appearance of a property and can be finished with a variety of textures and colors. Patios can be made of concrete, brick, stone, or other materials, and can be designed to incorporate features such as built-in seating, fire pits, and outdoor kitchens.

- Flooring: Concrete flooring is commonly used in garages, basements, commercial buildings, and industrial facilities. It is durable, easy to maintain, and can be designed to meet specific needs, such as non-slip surfaces in commercial kitchens or anti-static surfaces in electronics manufacturing facilities.

- Decorative Concrete: Decorative concrete is a type of concrete flatwork that is designed for aesthetic appeal, rather than just functional use. It can be used to create unique and eye-catching surfaces, such as stamped concrete patios, stained concrete driveways, or exposed aggregate walkways. Decorative concrete can also be designed to mimic the appearance of other materials, such as stone, brick, or wood, providing a more affordable and durable alternative.

- Stamped Concrete: Stamped concrete is a type of decorative concrete that is stamped with a pattern or texture to resemble other materials, such as brick, stone, or tile. The stamping process involves pressing a mat or stamp into the wet concrete to create a design, and then coloring the concrete with pigments to enhance the appearance of the design.

- Exposed Aggregate: Exposed aggregate is another type of decorative concrete that involves exposing the aggregate, or the stones and gravel in the concrete mixture, to create an attractive surface. This can be achieved by washing away the surface layer of concrete to reveal the aggregate, or by using a surface retarder to prevent the surface layer from setting, allowing the aggregate to be exposed after the surface is removed.

- Stained Concrete: Stained concrete is a type of decorative concrete that involves adding a color to the concrete to enhance its appearance. The stain is applied to the surface of the concrete and is absorbed into the concrete, creating a permanent and attractive finish. Stained concrete can be used to create a variety of effects, including a mottled appearance, a solid color, or a marbled effect.

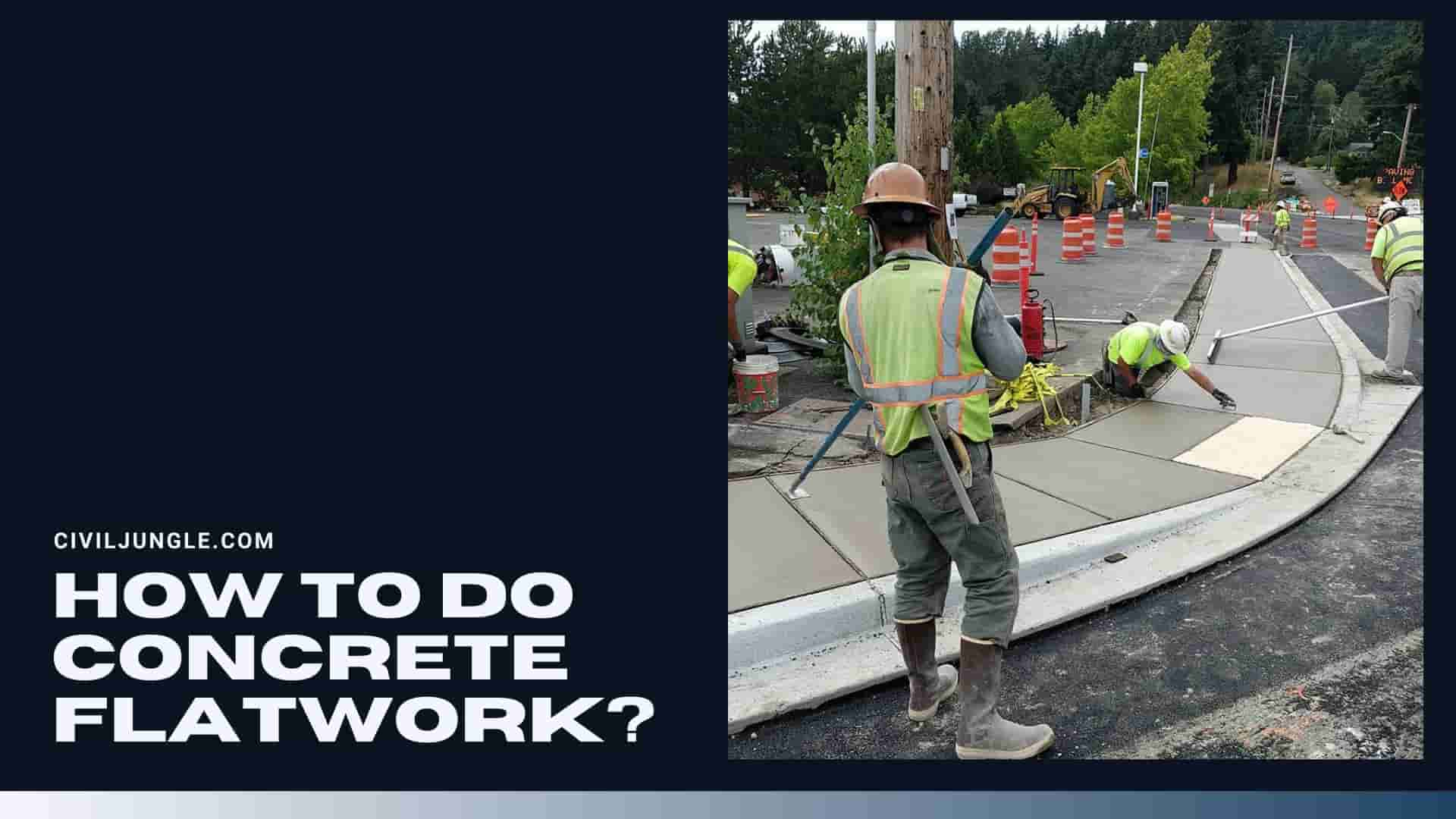

How To Do Concrete Flatwork?

Concrete flatwork is a complex process that requires proper planning, preparation, and execution to ensure a high-quality and long-lasting finish. Here are the steps involved in doing concrete flatwork:

- Planning: The first step in doing concrete flatwork is to plan the project. This involves determining the size and location of the concrete surface, selecting the type of concrete, and determining the type of finish that you want. You should also consider factors such as the weight the concrete will need to support, the drainage requirements, and the intended use of the concrete surface.

- Preparing the Site: The next step is to prepare the site for the concrete work. This involves removing any existing vegetation, grading the site to ensure proper drainage, and installing any necessary forms to define the shape of the concrete surface. If necessary, you may also need to install reinforcing mesh or rebar to provide additional support to the concrete.

- Mixing and Pouring the Concrete: The next step is to mix and pour the concrete. This involves mixing the dry ingredients, such as cement, sand, and aggregate, with water to form a wet concrete mixture. The mixture should be poured into the forms and leveled to ensure that the surface is even and smooth. If desired, you can add color to the concrete or use a trowel to create a specific finish.

- Curing the Concrete: After the concrete is poured, it must be allowed to cure for several days to ensure that it reaches its maximum strength. This involves keeping the concrete moist by covering it with plastic or spraying it with water. You should also avoid walking on the concrete during this time to prevent damage.

- Finishing the Concrete: After the concrete has cured, the final step is to finish the surface. This may involve smoothing the surface with a trowel, applying a sealer to protect the surface, or adding a decorative finish, such as stamped concrete, exposed aggregate, or stained concrete.

It is important to note that concrete flatwork is a complex and labor-intensive process, and should only be attempted by individuals with experience and the necessary equipment. If you are unsure about your ability to do the work, it is recommended that you hire a professional concrete contractor to complete the project for you.

In conclusion, doing concrete flatwork involves several steps, including planning, preparing the site, mixing and pouring the concrete, curing the concrete, and finishing the surface. With proper planning and execution, concrete flatwork can provide a strong and attractive surface that can last for decades.

Also Read: Slab Work

Concrete Flatwork Tools Needed

Concrete flatwork requires several specialized tools to ensure a smooth and even surface. Here are some of the most common tools used in concrete flatwork:

- Concrete Mixer: A concrete mixer is used to mix the dry ingredients, such as cement, sand, and aggregate, with water to form a wet concrete mixture. There are several types of concrete mixers, including drum mixers, pan mixers, and portable mixers, each with their own advantages and disadvantages.

- Bull Float: A bull float is a large flat tool used to smooth surface of wet concrete and remove air bubbles. The bull float is usually made of aluminum and has a handle attached to one end.

- Edging Tools: Edging tools are used to shape and define the edges of the concrete surface. They come in a variety of shapes and sizes and are used to create a clean, sharp edge along the perimeter of concrete.

- Trowels: Trowels are used to smooth and finish the surface of the concrete. There are several types of trowels, including finishing trowels, edging trowels, and concrete float trowels, each with their own specific uses.

- Concrete Vibrators: Concrete vibrators are used to remove air bubbles and ensure that the wet concrete mixture is compact and dense. Concrete vibrators come in a variety of shapes and sizes, including handheld models and larger, powered models.

- Concrete Curing Blanket: A concrete curing blanket is used to cover the freshly poured concrete to maintain moisture and prevent cracking. The blanket is usually made of a heavy-duty plastic material and is designed to be placed over the concrete and kept in place with stakes.

- Concrete Saws: Concrete saws are used to cut concrete into specific shapes and sizes. There are several types of concrete saws, including handheld saws, walk-behind saws, and large, self-propelled saws.

- Power Screed: A power screed is a power tool used to level and smooth the surface of wet concrete. The screed has a long blade that is moved across the surface of the concrete to create a flat and even surface.

- Stamps and Forms: Stamps and forms are used to create decorative patterns and designs in the concrete surface. There are a variety of stamps and forms available, including those that mimic the look of stone, brick, and wood.

These are just a few of the many tools that are commonly used in concrete flatwork. Depending on the size and complexity of the project, you may need additional tools, such as concrete forms, reinforcing mesh, and rebar.

When selecting tools for your concrete flatwork project, it is important to consider the size and type of concrete surface that you are working on, as well as your own skill level and experience.

Also Read: All About Concrete Bond | Will Concrete Bond to Concrete | How Concrete Adhesion Works

What Does Concrete Flatwork Cost?

The cost of concrete flatwork can vary widely based on several factors, including the size of the project, the complexity of the design, the materials used, and the location of the project. On average, concrete flatwork can cost anywhere from $4 to $15 per square foot, depending on these factors.

For a basic concrete slab, the average cost is usually around $6 to $8 per square foot, although this can vary widely depending on the thickness of the slab, the type of concrete used, and the location of the project. For more complex projects, such as stamped concrete or decorative concrete, the average cost can be much higher, often ranging from $10 to $15 per square foot or more.

It is important to keep in mind that the cost of concrete flatwork can be influenced by many factors, including the cost of labor, the cost of materials, and the local market conditions. Before beginning your project, it is a good idea to obtain quotes from several different concrete contractors to compare prices and get a better idea of total cost of the project.

In addition to the cost of the concrete itself, there are also other costs associated with concrete flatwork, such as the cost of tools and equipment, the cost of permits and inspections, and the cost of any additional work, such as grading and excavation.

To get a more accurate estimate of the total cost of your concrete flatwork project, it is important to factor in all of these costs and to work with a professional concrete contractor who can provide you with a detailed quote.

Concrete vs Pavers

Concrete and pavers are two common options for creating outdoor surfaces such as driveways, patios, and walkways. Both have their own advantages and disadvantages and the best option for your project will depend on your specific needs and preferences.

Concrete is a durable and versatile material that is easy to work with and can be poured into any shape or size. It is also relatively inexpensive compared to other materials, such as pavers. Concrete also has a smooth, even surface that is easy to clean and maintain.

On the other hand, pavers offer a more decorative and customizable option for outdoor surfaces. Pavers come in a variety of shapes, sizes, and colors, allowing you to create unique and eye-catching designs. They are also less prone to cracking and are a good option for areas that experience heavy foot traffic or heavy loads.

Another advantage of pavers is their ability to adapt to shifting soil and settling. Unlike concrete, which can crack and break under the weight of shifting soil, pavers can adjust and maintain their shape, making them a good option for areas with unstable soil conditions.

One potential disadvantage of pavers is their higher cost compared to concrete. Pavers are also more difficult to install and require more specialized skills and tools. Additionally, pavers can be prone to weed growth and may need to be sealed periodically to maintain their appearance.

Ultimately, the choice between concrete and pavers will depend on your specific needs and preferences. Both have their own advantages and disadvantages and the best option for your project will depend on factors such as the size of your project, your budget, the climate in your area, and your desired appearance.

Also, Read: Design of RCC Column

Concrete vs Asphalt

Concrete and asphalt are two popular options for paving outdoor surfaces such as driveways, parking lots, and roads. Both have their own unique advantages and disadvantages, and the best option for your project will depend on your specific needs and preferences.

Concrete is a durable and long-lasting material that is ideal for heavy-duty applications such as commercial and industrial sites. Concrete is also relatively low-maintenance and does not require frequent resurfacing or repair like asphalt. Additionally, concrete can be poured into any shape or size, making it a versatile option for custom projects.

On the other hand, asphalt is a more flexible and cost-effective option for paving outdoor surfaces. Asphalt is also quicker and easier to install compared to concrete, and can be resurfaced and repaired more easily as well. Additionally, asphalt has a smooth and even surface that is ideal for high-speed traffic and can provide better traction in wet conditions.

One potential disadvantage of asphalt is that it has a shorter lifespan compared to concrete and may require frequent resurfacing and repair. Asphalt is also more prone to cracking and damage from temperature changes, making it a less ideal option for areas with extreme temperature fluctuations.

Another consideration is the environmental impact of each material. Asphalt production is known to release pollutants and greenhouse gases into the atmosphere, whereas concrete production has a lower environmental impact.

Ultimately, the choice between concrete and asphalt will depend on your specific needs and preferences. Both have their own advantages and disadvantages and the best option for your project will depend on factors such as the size of your project, your budget, the climate in your area, and your desired appearance.

It is important to consider all of these factors and to work with a professional contractor to determine the best paving solution for your specific needs.

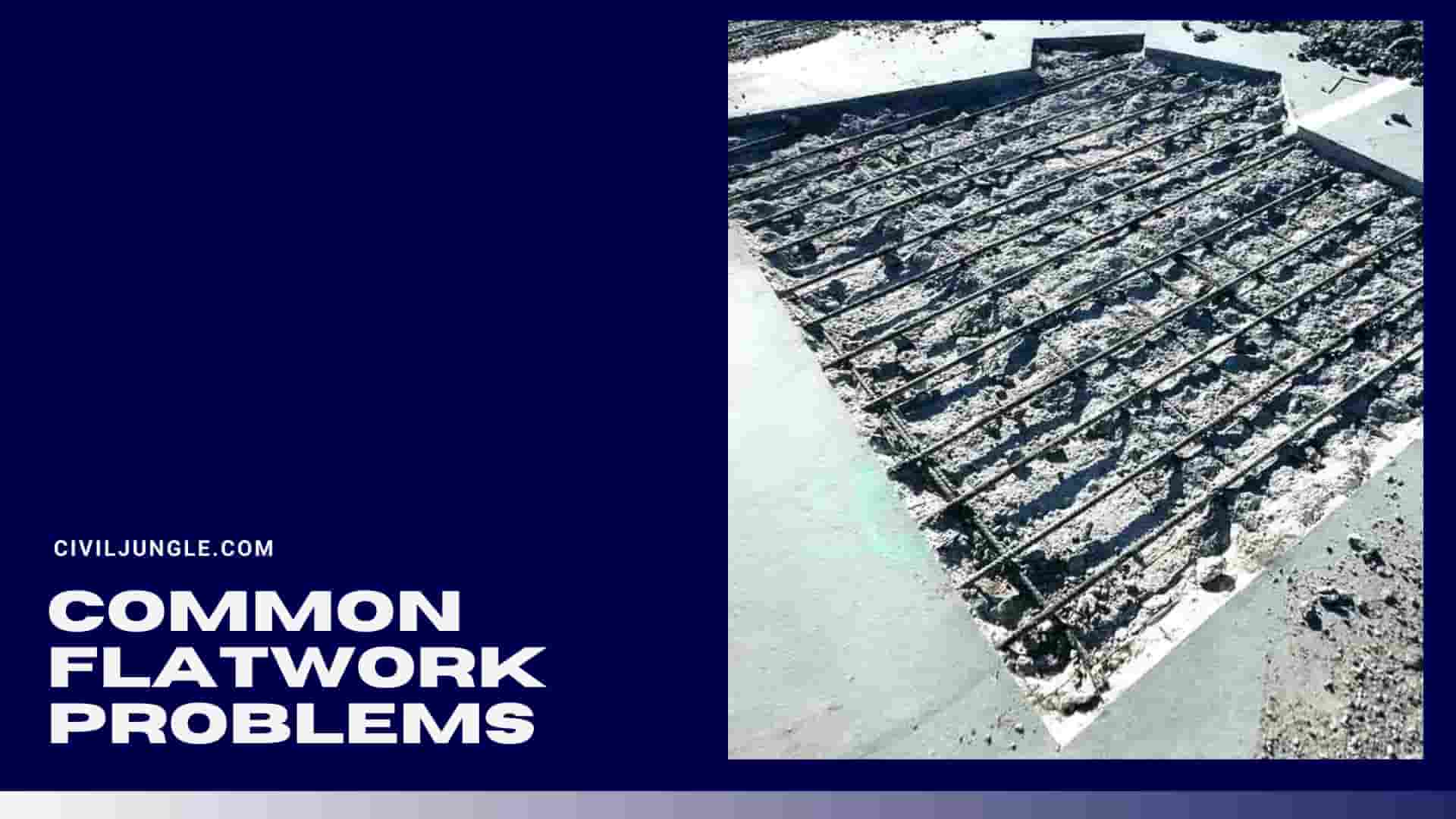

Common Flatwork Problems

Concrete flatwork can be subject to various problems that can impact the quality and durability of the finished surface. Some of the most common problems include:

- Cracking: Concrete is prone to cracking due to factors such as excessive stress, temperature changes, and improper curing.

- Settling: Over time, concrete can settle or sink in certain areas, causing uneven surfaces and tripping hazards.

- Staining: Concrete can be stained by spills, chemicals, and other substances, making it difficult to clean and maintain.

- Efflorescence: Efflorescence is a white, powdery substance that can form on the surface of concrete, indicating the presence of moisture.

- Shrinking: Concrete can shrink as it dries and cures, causing cracking and other structural problems.

- Alkali-Silica Reaction (ASR): ASR is a chemical reaction that can occur when certain types of aggregate react with the alkali in concrete, causing cracking and expansion.

To avoid these problems, it is important to use high-quality materials and to follow proper mixing and pouring procedures when installing concrete flatwork.

It is also important to work with a professional contractor who is experienced in installing concrete flatwork and can ensure that the finished surface is of the highest quality and durability.

Also, Read: How To Drill Into Concrete

Maintenance Tips

To keep concrete flatwork looking its best and to ensure its longevity, it is important to perform regular maintenance and care. Some of the main tips for maintaining concrete flatwork include:

- Clean Regularly: Concrete should be cleaned regularly to remove dirt, grime, and other substances that can stain or damage the surface. Use a mild soap and water or a specialized concrete cleaner to keep the surface clean and looking its best.

- Seal the Surface: Sealing the surface of concrete can help protect it from staining and other types of damage. Apply a concrete sealer every 1-2 years to ensure the best protection.

- Repair Cracks and Damage Promptly: If cracks or other types of damage occur, it is important to repair them promptly to prevent further deterioration of the surface.

- Avoid Harsh Chemicals: Concrete can be damaged by certain chemicals, such as salts, acids, and oils. Avoid using these types of substances near concrete surfaces and be sure to clean up any spills promptly.

- Maintain Proper Drainage: Proper drainage is essential for preventing damage to concrete surfaces. Ensure that gutters and downspouts are functioning properly and that water is directed away from concrete surfaces to prevent pooling and damage.

- Watch for Settling: Over time, concrete can settle or sink in certain areas, causing uneven surfaces and tripping hazards. Watch for settling and take steps to repair it promptly if it occurs.

By following these maintenance tips, you can help keep your concrete flatwork looking its best and ensure its longevity. It is also a good idea to work with a professional contractor who can provide advice and guidance on the best maintenance practices for your specific concrete surfaces.

Also Read: Concrete Finishes Types

Advantages of Concrete Flatwork

Concrete flatwork is a popular choice for paving outdoor surfaces, and there are several advantages to using this material. Some of the main advantages include:

- Durability: Concrete is a durable and long-lasting material that is ideal for heavy-duty applications such as commercial and industrial sites. Concrete can withstand heavy traffic and weather exposure, making it a good choice for areas that are subject to wear and tear.

- Low Maintenance: Concrete is relatively low-maintenance compared to other paving materials, and does not require frequent resurfacing or repair like asphalt. Additionally, concrete is resistant to staining, making it easy to clean and maintain.

- Versatility: Concrete can be poured into any shape or size, making it a versatile option for custom projects. This versatility also allows for the creation of unique and attractive designs that can add to the visual appeal of outdoor spaces.

- Cost-Effective: Despite its durability and long lifespan, concrete is a cost-effective paving option, especially when compared to high-end materials such as stone or brick.

- Safe: Concrete surfaces are slip-resistant, making them a safe choice for walkways, patios, and other outdoor areas where safety is a concern.

- Environmentally Friendly: Concrete production has a lower environmental impact compared to other paving materials, and concrete surfaces are also recyclable, making them a more sustainable option.

In conclusion, concrete flatwork is a durable, low-maintenance, and versatile paving option that offers a range of benefits for outdoor surfaces. Whether you are paving a driveway, patio, or walkway, concrete flatwork is a great choice for a high-quality, long-lasting surface.

What Is Flatwork Horses?

Flatwork is several dressage exercises that are performed while riding on flat ground. These exercises include circles, turns, transitions. It is a must for dressage horses, but it is beneficial for jumpers and eventers as well.

What Is Concrete Flatwork?

Concrete flatwork is any piece of concrete laid on a horizontal plane. Though, it can better be defined as driveways, sidewalks, curbs, parking lots, and many other concrete functions that surround us almost everywhere.

Concrete Flatwork Cost Per Square Foot

Concrete costs $4–$8 per square foot on average. This means you’ll pay $1,600–$3,200 for a 20-by-20 foot concrete slab, depending on the slab’s thickness and concrete type.

How to Do Concrete Flatwork?

- Ensure the voids are filled. Gently tap the sides of the form with a hammer to vibrate the concrete mixture and help it settle into any remaining spaces.

- Screed the concrete.

- Float the concrete surface.

- Add your finish texture.

- Install joints.

- Finish off the edges.

How to Prepare Ground for Concrete Patio?

Lay out the patio with batter boards and mason’s line. Remove the sod, dig out 8 inches of soil, and compact the exposed surface. Spread gravel on the surface in 2-inch layers, compacting each layer and adding gravel for a bed 4 inches deep. Install a second set of layout lines on stakes.

Concreting Tools and Equipment

Squeegees, edgers, and groovers can help you flatten everything out, and finishing trowels can assist with smoothing out the corners. Finally, nippers and rubbing bricks can help you put on the finishing touches. To help the concrete set more quickly, you have a variety of setting sprays to choose from.

Cost of 30×30 Concrete Slab 4 Inches Thick

A four-inch slab costs $2.83 per square foot. If you decide to add wire mesh, thick edges, and a vapor barrier, you may pay about $4.83 per square foot for material. What is this? At $2.83 per square foot, a 30×30 concrete slab costs $2,547.

How Much Does Concrete Cost Per Square Foot?

Concrete costs $4–$8 per square foot on average. This means a 20-by-30 foot concrete slab will cost $2,400–$4,800, depending on the slab’s thickness and the type of concrete needed.

60×100 Concrete Slab Cost

According to statistics, the national average cost of a concrete slab is about $6 per square foot. However, the prices can range from $4 to $8 per square foot based on the features of the slab. A 60×100-foot concrete slab may cost $24,000 to $48,000, with a median price of $36,000.

Cost of Concrete Pavers

Concrete pavers are the most popular and cost-effective paving material. They are highly customizable and ideal for a DIY project. They cost between $4 to $6 per square foot (not including installation).

Are Pavers Stronger Than Concrete?

As far as durability goes though if installed right, it is said that pavers are four times stronger than concrete slabs. Many of them even come with a lifetime guarantee, so look for that when searching for companies.

Concrete Vs Asphalt

Overall, the difference between asphalt and concrete driveways is that asphalt is less durable than concrete. With proper maintenance, it can last 30 years. Alternatively, concrete provides a sturdy, long-lasting option and can last homeowners 50+ years with occasional repairs and degreasing.

Asphalt Vs Concrete Driveway Resale Value

Higher resale value: Since asphalt is more affordable and a new driveway can increase your house’s worth, you’ll get a higher return on investment (ROI) for your asphalt driveway. Lasts longer all year long: On average, asphalt can last anywhere from 15 to 20 years.

Is Concrete or Asphalt Better for the Environment?

There are a variety of benefits to choosing concrete over asphalt cement. For one thing, concrete is a more sustainable material for the overall environment. An emphasis on eco-friendly construction practices could do wonders for your organization’s public image.

Is Asphalt Cheaper Than Concrete?

Asphalt is less expensive than concrete. Asphalt is a softer material, leading it to deteriorate faster and easier than concrete repairs. With proper maintenance, expensive repairs can be avoided.

Asphalt Concrete

Asphalt concrete usually refers to stabilized granular soil, where sand or well-graded aggregate is mixed with between 3% and 10% bitumen to provide a durable water- and abrasion-resistant structural layer.

Asphalt Vs Blacktop

Blacktop is heated to approximately 150 degrees celsius, whereas asphalt is only heated to 120 degrees celsius. Asphalt is has a higher bitumen content and for that reason is less porous and more resilient to wear and tear from high traffic and thus is the preferred choice for major highways.

Like this post? Share it with your friends!

Suggested Read –

Leave a Reply