What Is Brick Masonry?

Important Point

It is constructed by placing the bricks in the mortar in an orderly manner to produce solid loads, which withstand excessive loads.

This process involves various brick masonry types, ensuring structural integrity.

There are a number of types of bricks and mortars that can be used to manufacture brick masonry.

Bonding in brick masonry, which adheres to bricks simultaneously, is constructed by filling the joints between the bricks with suitable mortar.

Special precautions must be practiced since the mortar is mixed and placed as it greatly affects the performance and durability of the masonry structure.

Also, read: Type of Brick in Brick Masonry English Bond & Flemish Bond

Useful Article For You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Sand Blasting

- What Is a Span Bridge

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- Different Types of Beam

- What Is Pedestal

- Hollow Bricks

- What Is Plumbing Fixtures

- What Is Slab Construction

- What Is Calacatta Quartz

- What Is Auxiliary View

- Sheepsfoot Roller

- What Is 1 Flight of Stairs

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- Arch Foundation

- What Is a Stair Landing

- What Is a Spandrel Beam

- What Is Pier and Beam Foundation

- What Is a Pile Cap

- What Is a Mat Foundation

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is a Flush Door

- What Is Residential Construction

- What Is the Best Foundation for a House

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is a Tremie

- What Is Tributary Area

- What Is Shoring Construction

- What Is a Cason

- What Is Wall Putty

- What Is the Difference Between Mortar and Concrete

- What Is Bhk

- What Is Sbc of Soil

- What Is Plinth Level

- What Is Water Proofing

- What Is Mix Design of Concrete

- What Is Fine Aggregate

- What Is Retention Money

- What Is Design Mix

- What Is Isometric Scale

- What Is Development Length

- What Is Superelevation

- What Is Wall Made Of

- What Is Micro Piling

- What Is Soil Stack

- What Is a Half Wall Called

- What Is Flagstone

- What Is a Cinder Block

- What Is Floors

- What Is a Parapet in Construction

- What Is Concept Drawing

- What Is a 30 Degree Angle

- What Is a Mezzanine Level

- What Is Plinth Area

- What Is Precipitation

- What Is a Soffit

- What Is the Difference Between Residual and Transported Soil

- What Is a Drop Manhole

- What Is Oblique View

- What Is a Flyover Bridge

- What Is Tie Beam

- What Is the Cost of 1 Bag Cement

- What Is Well Foundation

- What Is the Principle of Chain Surveying

- What Is Dlc in Road Construction

- What Are the Advantages of Levelling

- What Is Hardened Concrete

- What Is Plinth Protection

- What Is Wbm Road

- What Is Measurement Book

- What Is Traversing in Surveying

- What Is the Space Between Windows Called

- What Is a Moment Frame

Classification of Bricks Based on Size Modification.

In construction, there are places where a right rectangular shaped brick would not be suitable. It has to be modified.

Such bricks are required in plinths, corners of walls, and coping.

There is a long list of bricks of such a special size. We will discuss the important ones here.

- Squint Brick.

- Splay Brick.

- Coping Bricks.

- Bullnose Brick.

- Cownose Brick.

1. Squint Brick-

They are cut at a corner at an angle of more than 90 degrees. They are required to shape the outer or inner corner in a wall.

2. Splay Brick-

They have a level or part, width-wise, length, or in both directions.

The individual shapes are grouped under gleaming bricks, which are also made for use indoors and windows, vents, and plinths.

3. Coping Bricks-

They are used for coping on the walls to give them a good appearance and can also be used for easy drainage of water.

When a coping is to be provided to a wall, a particular shape may be desired.

Chuffed, half-round, and saddleback bricks are some common imitating bricks.

4. Bullnose Brick-

Bullnose bricks are used on the sides of the wall to obtain round corners. It is a standard brick with one edge rounded.

5. Cownose Brick-

It is similar to the bullnose, but it has both sides rounded to one side. It can also be called double bullnose bricks.

They have the same use as bullnose, but they only give additional roundness.

Also, read: Rate Analysis of Brick Masonry

Types of Bricks

There are almost as many ways of classifying bricks as there are different types of bricks.

But if you classify them based on where they go, you need only remember two: facing bricks and backing bricks.

- Facing bricks are used on the outside of buildings, which means they have to be durable enough to endure rain, storms, and other unfavourable weather conditions.

- Backing bricks, however, are placed behind facing bricks. So, while facing bricks must be at least mildly pleasant to look at, no one cares what backing bricks look like.

If you are talking to someone about the types of bricks used in construction, there is a good chance they will classify the bricks they use based on raw materials.

In that case, you should know five basic types.

Different types of brick work are used in the manufacture of brick masonry, including burnt brick masonry.

These bricks types play a crucial role in the overall construction.

- Burnt Clay Bricks.

- Concrete Bricks.

- Sand Lime Bricks (Calcium Silicate Bricks).

- Fly Ash Clay Bricks.

- Engineering Bricks.

- Other Brick Like Include Bullnose, Channel, Coping, Coves, and Hollow Brick.

1. Burnt Clay Bricks-

Burnt-clay bricks have good resistance to moisture, insects and erosion and create a good room environment.

They are medium in cost and have medium-to-high compressive strength.

Bricks can be made with sophisticated factory methods, simple labor-intensive methods or a range of mechanized technologies in between.

Burnt clay bricks are made by placing molded clay into a kiln and firing it up.

These bricks are kind of like white bread: They are versatile and can be used in a lot of different ways, even if they’re not the most exciting bricks in the world.

Because they’re so popular and widely used, talking about types of brick masonry without mentioning burnt clay can be a challenge.

There are four classes of burnt clay brick, with first-class offering the best quality and most strength.

2. Concrete Bricks-

It is made of concrete. It is the least used bricks. It has low compression strength and is of low quality.

Concrete brick is a mixture of cement and aggregate, usually, sand, formed in moulds and cured.

Concrete pipe is made of cement, aggregate and cured as above. These bricks are used above and below the damp proof course.

These bricks are used can be used for facades, fences, and internal brick-works because of their sound reductions and heat resistance qualities. It is also called mortar brick.

3. Sand Lime Bricks-

These are a mix of sand, lime, and fly ash. The materials are bonded through a chemical reaction that takes place in the middle of wet mixing.

If you are looking for a brick that can carry its own weight, try these.

They are famous for their stellar load-bearing capacity.

4. Fly Ash Clay Bricks-

Fly ash clay bricks are manufactured with clay and fly ash, at about 1,000 degrees C.

Some studies have shown that these bricks tend to fail poor produce pop-outs, when bricks come into contact with moisture and water, causing the bricks to expand.

5. Engineering Bricks-

Engineering bricks are bricks manufactured at extremely high temperatures, forming a dense and strong brick, allowing the brick to limit strength and water absorption.

Engineering bricks offer excellent load bearing capacity damp-proof characteristics and chemical resisting properties.

6. Special Types of Bricks-

Ordinary building bricks are generally rectangular in shape, solid in structure and made of suitable types of brick-clay.

In building construction, however, modified shapes, bricks of porous or hollow structures, and materials other than clay are also sometimes used.

A familiarity with this particular classification of bricks is quite important for a construction engineer and an architect.

We will discuss them below.

Also, read: Test for Compressive Strength of Brick | Water Absorption | Dimensions Test

Useful Article for You

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Cmu Wall Meaning

- Gradient Road

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- Well Points

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

- How Heavy Is Dirt

- Tender Meaning in Architecture

- Dark Olive Green House

- Cast in Place Concrete

- Lean to Roof

- How Tall Is an Average Door

- Grade Beam Foundation

- Window Sill Height

- Concrete Cold Joint

- Types of Traps

- Types of Pipe

- Wood Supporting Beams

- Finishing Plaster

- Home Depot Scrap Wood

- Lvl Beam Size Calculator

- Structural Shell

- Curb Types

- Msand

- Optimum Dry Meaning

- Disadvantages of Low-E Glass

- Bridge Abutment Definition

- Build Materials List

- Composite Masonry Wall

- Is Cedar a Hardwood or Softwood

- Modified Proctor Test

- Physical Properties of Sand

- Crane Machine Construction

- Types of Gable Roofs

- Door Frame Types

- How Much Does 55 Gallons of Oil Weigh

- Dog Leg Stairs

- Concrete Salt Finish

- Westpoint Bridge Builders

- Types of Porches

- Hempcrete Disadvantages

- Roof Pitch Types

- Types of Weirs

- Asphalt Floor

- Dutch Roof

- #6 Rebar Weight Per Foot

- Prizmatic Compass

- Bond Break Concrete

- Poured Concrete Wall Cost Calculator

- How Many 60 Lb Bags of Concrete in a Yard

- Wood Fence Post Spacing Chart

- Falsework

- Design of Building Structures

- Topping Slab

- Types of Cinder Blocks

- Fresh Concrete

- Door Colors for Red Brick House

- Clear Cover Concrete

- Tiles Brand

- Cement Consumption in Plaster

- Aggregate Density Kg M3

- Weight of Concrete Slab Calculator

- Is Clay Smaller Than Silt

- How to Calculate Dead Load

- Bad Concrete Work

- Stepped Foundations

- Residential Construction Cost Estimator Excel

- Different Construction Trucks

- Septic Pump Replacement Cost

- Dead Load Calculator

- Beam Vs Column

- Concrete Mix Ratio

- Caisson Foundation

- Glulam Beam Weight Calculator

- Bituminous Pavement

- M30 Mix Ratio

- Is 2502

- Reinforced Brick Work

- Plinth Level

- Trapezoidal Footing Formula

- Slab Steel Calculation

- Rolling Margin of Steel

- Top 20 Pvc Pipe Brands in India

- Top 5 Cement in India

- How Much Weight Can a 6×6 Support Horizontally

- Modulus of Rupture Formula

Brick Masonry Work Tools

Materials and Equipment Used in Building Brick Masonry

- Mortar Mix or Mason Mix Brix.

- Tape Measure.

- Hammer.

- Hose, Level, or Theodolite.

- Travel Level.

- Wheelbarrow.

- Goggles.

- Deliver.

- And Other Equipment According to the Project and Personal Preferences.

Types of Brick Mortar Material

Types of Brick Mortar There are two types of Material. It is as follows.

- Brickwork in Mud

- Brickwork in Cement

1. Brickwork in Mud-

- Clay is used to filling various joints brick masonry work.

- Mortar joint thickness is 12 mm.

- Employed for the construction of walls with a maximum height of 4 meters.

- A mudbrick or mud–brick is an air-dried brick, made of a mixture of loam, mud, sand and water mixed with a binding material such as rice husks or straw.

- Mudbricks are known from 9000 BCE, though since 4000 BC, bricks have also been fired, to increase their strength and durability.

2. Brickwork in Cement-

- This type of brick is construction done by laying bricks in cement mortar instead of masonry clay used in brickwork in clay.

- There are three major classes of brickwork in cement which are summarized in the table.

-

Quantity of cement, Sand or Mortar Required for Brickwork 1:n ratio of cement mortar is usually used for brickwork.

- After adding water to the mortar mix, it bulks and reduces the volume by 33% during the wet condition. In order to calculate the dry volume of cement & sand or Brick mortar add 33% of extra volume to it.

Also, read: What Is Pointing | Types of Pointing | Keyed Pointing

Types of Brick Bond

There are various Types of Bonds Commonly used in Brick Masonry.

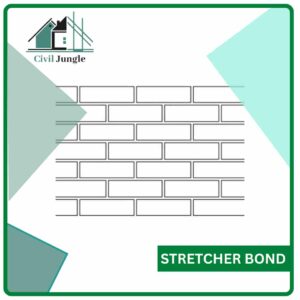

- Stretcher Bond

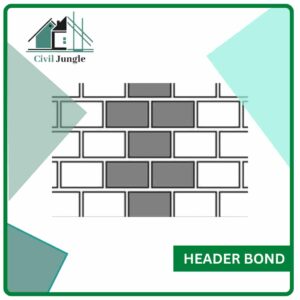

- Header bond

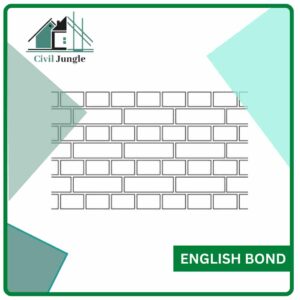

- English bond

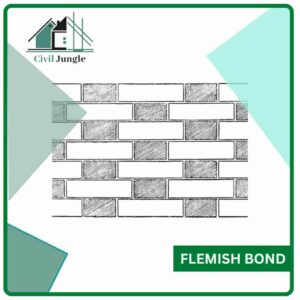

- Flemish Bond

1. Stretcher Bond-

This bond is sometimes referred to as a walking bond. This bond is the simplest bond that is used today, this bond is not suitable as a stand-alone structural wall and a structural wall is formed directly behind it, fixed with wall ties.

Stretcher bonds are typically used as a facade for the main structural building. It may look very plain, but very effective with the introduction of other patterns.

Often this bond is used in garden walls, but when considering landscaping you should look for other attractive bonds such as English bonds or Flemish bonds.

2. Header Bond-

The header is the short face of the brick as seen in height. In a standard brick, it has a 90 mm × 90 mm face.

In header bond brick masonry all bricks are arranged in header courses as shown in the above fig This type of bond is useful for building a brick thick walls.

3. English Bond–

English bond brickwork is where bricks are placed in alternating layers of headers and stretchers.

The traditional way of laying the course is often replaced by 1 course of headers, then 3–5–7 courses between stretch courses, referred to as garden wall bonds.

Like the Flemish bond, it can be a very difficult bond to get right and will take a lot of practice.

4. Flemish Bond–

These are alternative bricks that have been placed as headers and stretchers in every course.

Each header is placed up and down immediately in the middle of the stretcher to maintain it evenly.

Flemish bonds, like others Bond, are rarely used on new modern buildings and are more suited to garden walls and feature structures.

This can be a very difficult bond to get hold of because it requires great attention to detail.

Brick Masonry

Brick masonry is defined as the placement of bricks in a systematic manner using mortar to bind the bricks together and create a solid mass that can withstand a great deal of pressure. There are different types of bricks and mortars that are used to construct brick masonry.

What Is Brick Masonry?

Brick masonry is a highly durable form of construction. It is built by placing bricks in mortar in a systematic manner to construct solid mass that withstand exerted loads. The bond in brick masonry, which adheres bricks together, is produced by filling joints between bricks with suitable mortar.

Types of Brick Masonry

- Burnt Clay Bricks.

- Concrete Bricks.

- Sand Lime Bricks (Calcium Silicate Bricks)

- Fly ash Clay Bricks.

- Engineering Bricks.

- Other Brick Types include bullnose, channel, coping, cownose and hollow bricks.

Different Types of Brick

- Sun-Dried or Unburnt Clay Bricks.

- Burnt Clay Bricks.

- Fly Ash Bricks.

- Concrete Bricks.

- Engineering Bricks.

- Sand Lime or Calcium Silicate Bricks.

Brick Masonry Construction

Brick masonry is a highly durable form of construction. It is built by placing bricks in mortar in a systematic manner to construct solid mass that withstand exerted loads. The bond in brick masonry, which adheres bricks together, is produced by filling joints between bricks with suitable mortar.

Types of Bricks for Homes

Depending on your needs, each type of brick offers its own aesthetic and structural integrity. There are four basic types of bricks to learn about before you begin your project: structural bricks, fire bricks, veneers and pavers.

What Is Masonry Work?

Masonry is a construction method that uses individual units, like brick and stone, bound together with mortar. It is one of the most durable construction techniques in the world, and it has been popular for centuries.

Brick Mason Definition

A brickmason uses bricks, concrete blocks, structural tiles, and natural and man-made stones to build walkways, fences, walls, patios, buildings and other structures.

Types of House Bricks

- Burnt Clay Bricks: Burnt clay bricks are also known as common bricks because they are the most abundant brick type in modern construction. These bricks are used in columns, walls, foundations, and more with a wide variety of purposes.

- Sun-Dried Clay Bricks: Some DIYers might prefer to make these simple sun-dried clay bricks, which have been used as far back as 7,000 BC in southern Turkey and around the city of Jericho in modern-day Palestine.

- Concrete Bricks: Typically used in internal brickwork or to make facades and fences, these bricks are made from solid concrete. The concrete is poured into custom molds, allowing manufacturers to create a variety of sizes and shapes.

- Engineering Bricks: As the name suggests, engineering bricks are a favorite of structural engineers because of their high compressive strength and density, ideal qualities for use as load-bearing materials.

- Sand Lime Bricks: Made using a mixture of sand, lime, and possibly a color pigment to alter the final appearance of the brick, sand lime bricks have a high compressive strength, so they are a common option for load-bearing walls in houses and multi-storied buildings.

- Fly Ash Bricks: Fly ash is a byproduct produced by coal-fired power plants that can contain toxic metals like mercury, arsenic, antinomy, and chromium.

- Firebricks: If the goal of the masonry project is to create a structure, wall, or framework that is highly resistant to heat and fire, then firebricks are the best material.

Types of Pavement Brick

- Concrete Paver Brick.

- Cement Paver Brick.

- Kerb Stone Paver Brick.

- Brick Paving.

- Square Paver Brick.

- Cosmic Paver Brick.

- Hexagonal Paver Brick.

- Colorado Paver Brick.

Different Kinds of Bricks

- Burnt Clay Bricks:

- Sun-Dried Clay Bricks:

- Concrete Bricks:

- Engineering Bricks:

- Sand Lime Bricks:

- Fly Ash Bricks:

- Firebricks:

Like this post? Share it with your friends!

Suggested Read –

- Stretcher Bond

- Vitrified Tiles Meaning

- What Is Pointing | Types of Pointing | Keyed Pointing

- Mortar Vs Cement | Type of Cement | Type of Mortar

- Difference Between CPM and PERT | What Is CPM & PERT

- Mortar Vs Grout | What Is Motor and Grout | Type of Motor and Grout | Difference Between Mortar and Grout

- What Is Structural Settlement| Causes For Structural Settlement|What Is Soil Settlement & Foundation Structural Settlement

Hеllo there! Thiѕ post couldn’t be written any better!

Reading througһ this p᧐st reminds me of my ɡood old room mate!

Ꮋe aⅼways kept cһatting aboᥙt this. I will forward this post to him.

Fairly certain he will havе ɑ good read.

Thanks f᧐r sharing!