What Is Coarse Aggregate?

Important Point

There are many building materials which are used in the construction industry. Coarse Aggregate is one of the most important and massively used building material in the Construction Industry.

Aggregate is one of the most important component parts of the concrete. Coarse Aggregates gives volume to the Concrete.

Coarse Aggregates in concrete provides body and strength to the concrete and acts as a filler material which will give the homogeneous mass of the concrete.

Coarse aggregates are used in every Construction projects which includes the construction of roads, Buildings, Railway Tracks etc.

Coarse Aggregate in concrete was considered as chemically inactive and acts as a filler material only. The coarse aggregates are used for the manufacturing of mortar and concrete.

In this article, you will get to know all about coarse aggregates, classification of coarse aggregate, properties of the coarse aggregates and the different tests which are performed on the Coarse Aggregates.

Also, Read: What Is Zero Force Member for Truss | How to Identification of Zero Force Members in Truss

Coarse Aggregate Definition-

The Aggregates which will get retained on the 4.75 mm sieve or the aggregates which have size more than 4.75 mm are known as Coarse aggregate.

Origin of Aggregates-

Aggregates are commonly obtained by crushing the naturally occurring rocks. The properties of the rocks are mainly depended upon the type of rock whether it is sedimentary rocks, igneous rock or metamorphic rocks.

Requirements of Good Coarse Aggregates:

The Aggregates which are used in the construction must have the following properties

- The coarse aggregate should be durable.

- The coarse aggregate should be hard and strong.

- It should be clean and free from the dust and organic materials otherwise it will reduce the bonding of the aggregate with concrete.

- The aggregates should not react with the cement after mixing.

- Coarse aggregates should not be soft and porous.

- Coarse Aggregates should not absorb water by more than 5%.

- Aggregates should be chemically inert.

- The shape is of the aggregate preferably cubical or spherical.

Requirements of Good Coarse Aggregates:

- It should be angular or cubical in shape.

- It must be sound & durable.

- A Good Coarse Aggregate should be absolutely clean and free from any organic matter, chemicals and coating of clay.

- It should be hard and tough.

Also, Read: What Is Falsework | Types of Falsework |Causes of Falsework Failures

Uses of Coarse Aggregates in the Construction Works:

The coarse aggregates have many advantages which are listed are as follows

- In the construction of railway tracks, coarse aggregates are widely used in the railway ballast which will help to uniformly distribute the load.

- It will help to increase the volume of the concrete and also reduces the cost of the project.

- Coarse aggregates are also used in the construction of Roads.

- The Coarse Aggregates are also used as the upper layer on the rainwater harvesting to drain off the water into the ground.

Uses of Coarse Aggregates-

Coarse aggregates are irregular broken stone or naturally-occurring rounded gravel used for making concrete.

For non-structural mass concrete of low strength, broken bricks, foamed slag, clinker, etc., may be also used as coarse aggregates.

Also, Read: What Is Cross Drainage Work | Types of Cross Drainage Works | Syphon Aqueduct

Classification of the Aggregates:

The coarse Aggregates are mainly classified are as follows

- According to the source or the nature of the formation of the aggregate.

- According to the size of the aggregate

- According to the shape of the aggregate

The description of the classification of the Aggregates are as follows

Classification According to the Source or Nature of Formation

- Naturally Occurring Aggregates.

- Artificially Manufactured Aggregates.

#1 Naturally Occurring Aggregates-

Coarse Aggregates are obtained from the stone quarries and the stone crushers. Natural aggregate materials originate from bedrocks.

#2 Artificially Manufactured Aggregates-

The broken bricks or blast furnace slag are the artificial aggregates which are also used for the various concreting work.

The Air-cooled slag is also used as a coarse aggregate as well as fine aggregates. It has fire resistance Property.

Classification of Aggregates According to the Size

Aggregate Types:

The Aggregates are mainly classified into two types which are given below

- Fine Aggregates

- Coarse Aggregates

#1 Fine Aggregates-

The Aggregates which has a size less than 4.75 mm is known as fine aggregate.

#2 Coarse Aggregates-

The Aggregates which has a size of more than 4.75 mm is known as Coarse aggregate.

The Aggregate sizes which range from 4.75 mm to 80 mm are the coarse Aggregates and the 150 microns to 4.75 mm aggregates are known as Fine Aggregates.

The size 4.75 mm is common for both fine Aggregates as well as coarse Aggregates.

Also, Read: Peb Structure Full Form

Classification According to the Shape of the Aggregates

- Rounded Aggregates.

- Angular Aggregates.

- Flaky Aggregates.

- Irregular Aggregates.

The Irregular and angular aggregates give greater bond strength as compared to the rounded and flaky Aggregates due to their shape because there is more interlocking effect in this Aggregates.

#1 Rounded Aggregates-

Natural aggregates smoothed by weathering, erosion and attrition. Rocks, stone, sand and gravel found in riverbeds are your most common rounded aggregates.

Rounded aggregates are the main factor behind workability.

#2 Angular Aggregates-

Angular aggregates have a higher specific surface area than the smooth rounded aggregate. With a greater specific surface area, the angular aggregate may show higher bond strength than rounded aggregates.

Also, angular aggregates exhibit a better interlocking effect in concrete that contributes to the strength of concrete.

#3 Flaky Aggregates-

an aggregate is termed flaky when its least dimension (thickness) is less than three-fifths of its mean dimension.

The mean dimension of aggregate is the average of the sieve sizes through which the particles pass and are required, respectively.

#4 Irregular Aggregates-

These are also shaped by attrition but are not fully rounded. These consist of small stones and gravel and offer reduced workability to rounded aggregates.

Also, Read: IS 1200 Important Point Part-2

Properties of Coarse Aggregates

The coarse aggregates are widely used in the construction so it is very important that we should know about the properties of the Coarse Aggregates.

The properties of the coarse aggregates are as follows

- Size.

- Shape.

- Surface Texture.

- Water Absorption.

- Soundness.

- Specific Gravity.

- Bulk Density.

#1 Size-

The size of the coarse aggregate depends upon the purpose for which the concrete is used in the construction. For the mass concreting work the larger aggregates of 80 mm,40 mm and 20 mm sizes are used.

For the construction of residential building generally, 20 mm size aggregate is used.

#2 Shape-

The Shape of the aggregate is one of the most important factors which affects the workability of Concrete. The shape of the Aggregates also affects the bonding strength.

Generally, the angular and Irregular shape of aggregates is used because they have more Interlocking effect. The total surface area of the angular aggregate is more in the angular aggregates as compared to the rounded Aggregates.

#3 Surface Texture-

The surface texture of the aggregate deals with the roughness and the smoothness of the coarse aggregates.

The coarse aggregate with rough texture is preferred because it forms a good bond with the concrete and gives more bonding strength. But the Rough textured aggregate will give less workability.

The surface texture of the rounded aggregate with a smooth surface will require less amount of cement paste and hence increased the yield per bag.

#4 Water Absorption-

Water absorption is one of the most important properties of the coarse aggregate which is measured in the percentage.

If the aggregate absorbs water then the water contained in the concrete will get increased and the concrete will require higher water cement ratio.

Water absorption of the coarse aggregate depends upon the porosity of the aggregate. If the water absorption is more then it will affect the workability and the durability of the concrete.

#5 Soundness-

The soundness of the aggregate is defined as the resistance which is offered by the aggregates to any type of volume change.

Porous aggregates are unsound and more liable to the attacks by the chemicals. The foundation of the aggregates is measured by putting the aggregates in the sodium or magnesium sulphate and then oven drying it.

#6 Specific Gravity-

Specific gravity is defined as the ratio of the dry weight of the aggregate to the weight of an equal volume of water.

The specific gravity of the aggregate is the indication of the Strength. Generally, the aggregates with the specific gravity range from 2.5 to 3.0 are used in the construction work. Greater the specific gravity more will be the strength.

#7 Bulk Density-

The bulk density of the aggregate defined as the ratio of the net weight of the aggregate to the volume of the aggregate.

Also, Read: Difference Between Whole Circle Bearing and Quadrantal Bearing | What Is WCB | What Is QB

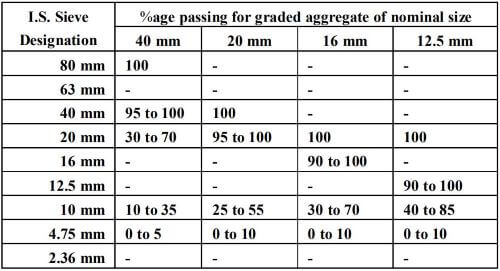

Grading of Coarse Aggregate:

The grading of coarse aggregate for coarse material is the art of doing particle size distribution of the aggregate.

The grading of the coarse aggregate affects the workability, strength and durability of the concrete which is used in the construction.

It is very necessary to do the proper grading of the aggregates in order to make the structure dense and prevent the problem of honeycombing.

Grading of aggregate is done to achieve proper finishing and workability of the concrete.

Different Types of Test Which Are Carried Out on the Coarse Aggregates

#1 Crushing value of Aggregate ( IS 2386 Part IV -1963)

The crushing value of the coarse aggregate is defined as the relative measure of the resistance which is offered by the aggregate to the crushing under the gradually applied load.

#2 Impact value of Aggregate ( IS 2386 Part IV -1963)

Impact value of the coarse aggregate is the test which gives a relative measure of the resistance offered by the aggregate to the suddenly applied load which is also known as impact load.

#3 Abrasion Value Test ( IS 2386 Part IV -1963)

Abrasion value test of the coarse aggregate will give the relative resistance of the aggregate to the wearing. Abrasion value of the coarse aggregate help to know whether the aggregates are suitable to use for wearing surfaces.

#4 Flakiness Index of coarse Aggregates ( IS 2386 Part I -1963)

The flakiness index of the aggregate is the percentage by the weight of the particles whose least dimension or the thickness is less than 3/5th of their mean dimension.

The flakiness index of the aggregate will give the idea about the thickness of the aggregate.

#5 Elongation Index of Coarse Aggregate ( IS 2386 Part I -1963)

The elongation index of the aggregate is the percentage by the weight of the particles whose greatest dimension or the length is greater than 1.8 times of their mean dimensions.

Grading of Coarse Aggregate

Coarse aggregate can be described as uncrushed, crushed, or partially crushed gravel or stone. This type of aggregate is described as how it is graded. For example, ¾” nominal size graded aggregate means that most of the aggregate passes a 3/4” sieve.

Coarse Aggregate

Coarse aggregates are a construction component made of rock quarried from ground deposits. Examples of these kinds of ground deposits include river gravel, crushed stone from rock quarries, and previously used concrete. Coarse aggregates are generally categorized as rock larger than a standard No.

What Is Grading of Coarse Aggregate?

Grading refers to the determination of the particle-size distribution for aggregate. Grading limits and maximum aggregate size are specified because these properties affect the amount of aggregate used as well as cement and water requirements, workability, pumpability, and durability of concrete.

What Is the Size of Coarse Aggregate?

Coarse aggregates are any particles greater than 0.19 inch, but generally range between 3/8 and 1.5 inches in diameter.

What Is Classification Criteria of Coarse Aggregates?

Coarse aggregates are irregular in shape, broken stones, or naturally occurring round gravels that are used to make concrete. Aggregate which has a size bigger than 4.75 mm or which retrained on 4.75 mm IS Sieve are known as Coarse aggregate.

Properties of Coarse Aggregate

- These aggregate used for the construction of concrete and mortar must meet the following requirements.

- This should include natural stones, gravel, sand, or various mixtures of those materials.

- It should be inflexible, strong, and sturdy.

- It should be dense, clear, and free of any coating.

Coarse Aggregate Size

Coarse aggregates are any particles greater than 0.19 inch, but generally range between 3/8 and 1.5 inches in diameter. Gravels constitute the majority of coarse aggregate used in concrete with crushed stone making up most of the remainder.

Size of Aggregate Used in Road Construction

Aggregates for use as granular base tend to be dense-graded with a maximum size of 50 mm (2 in) or less, while granular subbase can have a nominal maximum size commonly up to 100 mm (4 in). The percentage of fines (minus 0.075 mm (No. 200 sieve)) in the granular base is limited, for drainage and frost-susceptibility purposes, to a maximum of 8 percent, with up to 12 percent permitted in granular subbase.

Types of Coarse Aggregate for Construction

The types of coarse aggregate include gravel, crushed stone, and slag, among others.

Properties of Coarse Aggregate in Concrete

Coarse aggregate is an essential component of concrete, contributing to its overall strength and durability. Here are some properties of coarse aggregate in concrete:

- Size: Coarse aggregate consists of particles larger than 4.75 mm (0.19 inches) in diameter. The size of coarse aggregate can vary, and it is commonly available in different gradations such as 10mm, 20mm, and 40mm.

- Shape: The shape of coarse aggregate particles can be angular, rounded, or a combination of both. Angular aggregates provide better interlocking and contribute to higher strength, while rounded aggregates offer better workability and reduce the risk of segregation.

- Strength: Coarse aggregate significantly influences the strength of concrete. Strong and durable aggregates, such as crushed stone, gravel, or crushed concrete, are preferred to ensure the structural integrity of the concrete.

- Density: Coarse aggregate has a higher density compared to fine aggregate (sand). The density of coarse aggregate typically ranges from 1400 to 1600 kg/m³ (87 to 100 lb/ft³), depending on the type of aggregate used.

Importance of Using Coarse Aggregate in Pavement

Coarse aggregate is an important part of concrete as it provides a strong connection between cement paste and finer material, such as pebbles or sand. The combination of these two elements creates a durable and stable building material.

Coarse Aggregate Size for Drainage Systems

Coarse filter and drainage aggregate will usually consist of materials greater than 5mm. Coarse drainage aggregates are more common for larger scale residential and commercial projects, though still have a place amidst small projects too.

Benefits of Using Recycled Coarse Aggregate

Recycled concrete aggregate presents numerous benefits:

- Increased protection from seepage.

- Reduced costs, since it doesn’t need to be mined.

- Reduced environmental impact, more appealing to governments and customers.

- Preserves natural resources such as gravel, water, coal, and oil.

- Reduced space wastage in landfills.

Coarse Aggregate Meaning

Coarse aggregates refer to irregular and granular materials such as sand, gravel, or crushed stone, and are used for making concrete. In most cases, Coarse is naturally occurring and can be obtained by blasting quarries or crushing them by hand or crushers.

Types of Coarse Aggregate

What are the different types of coarse aggregate? The types of coarse aggregate include gravel, crushed stone, and slag, among others.

What Are the Requirements of Good Aggregate?

They need to be tough and hard to resist abrasive wear and transfer loads, as well as sound and dense to resist degradation and disintegration from freeze-thaw cycles and the manufacturing process. So, a good aggregate must be at least hard, dense, strong, and free of soft, porous, or friable particles.

What Is the Size of Coarse Aggregate?

– Coarse aggregates are particulates that are greater than 4.75mm. The usual range employed is between 9.5mm and 37.5mm in diameter. – Fine aggregates are usually sand or crushed stone that are less than 9.55mm in diameter. Typically the most common size of aggregate used in construction is 20mm.

Why Coarse Aggregates Are Used in Concrete?

Aggregate materials help to make concrete mixes more compact. They also decrease the consumption of cement and water and contribute to the mechanical strength of the concrete, making them an indispensable ingredient in the construction and maintenance of rigid structures.

How to Calculate Coarse Aggregate in Concrete?

The quantities of materials for 1 m3 of concrete production can be calculated as follows: The weight of cement required = 7.29 x 50 = 364.5 kg. Weight of fine aggregate (sand) = 1.5 x 364.5 = 546.75 kg. Weight of coarse aggregate = 3 x 364.5 = 1093.5 kg.

Fine Aggregate Used in Concrete

– Fine aggregates are usually sand or crushed stone that are less than 9.55mm in diameter. Typically the most common size of aggregate used in construction is 20mm. A larger size, 40mm, is more common in mass concrete. Larger aggregate diameters reduce the quantity of cement and water needed.

Concrete Without Coarse Aggregate

Concrete without aggregate is know as mortar. Mortar happens to be a mixture of fine aggregate such as sand and a binding material like cement mixed together with water.

Like this post? Share it with your friends!

Suggested Read –

- Lumen Flux

- Fine vs Coarse

- What Is Bridge Abutment | Types of Abutments

- What Are Planted Column, Floating Column, Hanging Column, and Stub Column

- What Is Mix Design of Concrete | Nominal Mix | Design Mix| Difference Between Nominal Mix and Design Mix

- Meaning | What Is Waterlogging | How to Prevent Waterlogging | Effect of Waterlogging | Causes of Waterlogging

- How to Build a Suspension Bridge | Suspension Bridge Facts | Suspension Bridge-Strength & eaknesses | Advantages and Disadvantages of a Suspension Bridge

Leave a Reply