What Is Glass Fiber Reinforced Gypsum?

Important Point

Mainly the structures of modern buildings are made of different types of materials. Regardless of whether you are a builder, architect, engineer, or contractor, it is extremely important to know the nuances of the building materials used popularly.

The knowledge of different types of construction materials, together with the details of their properties and their various uses for different purposes, act as an important resource in the hands of the builders in obtaining savings in the cost of construction.

In addition to material savings, the precise use of materials results in better structural strength, aesthetic appearance, and functional efficiency.

In this article, we will discuss one of these building materials, popularly called “GFRG,” which stands for Glass Fiber Reinforced Gypsum.

Also, read: Abrasion Test | Test to Determine the Abrasion Value | Abrasion Test Principle | Important of Abrasion Test

What is the GFRG Panel?

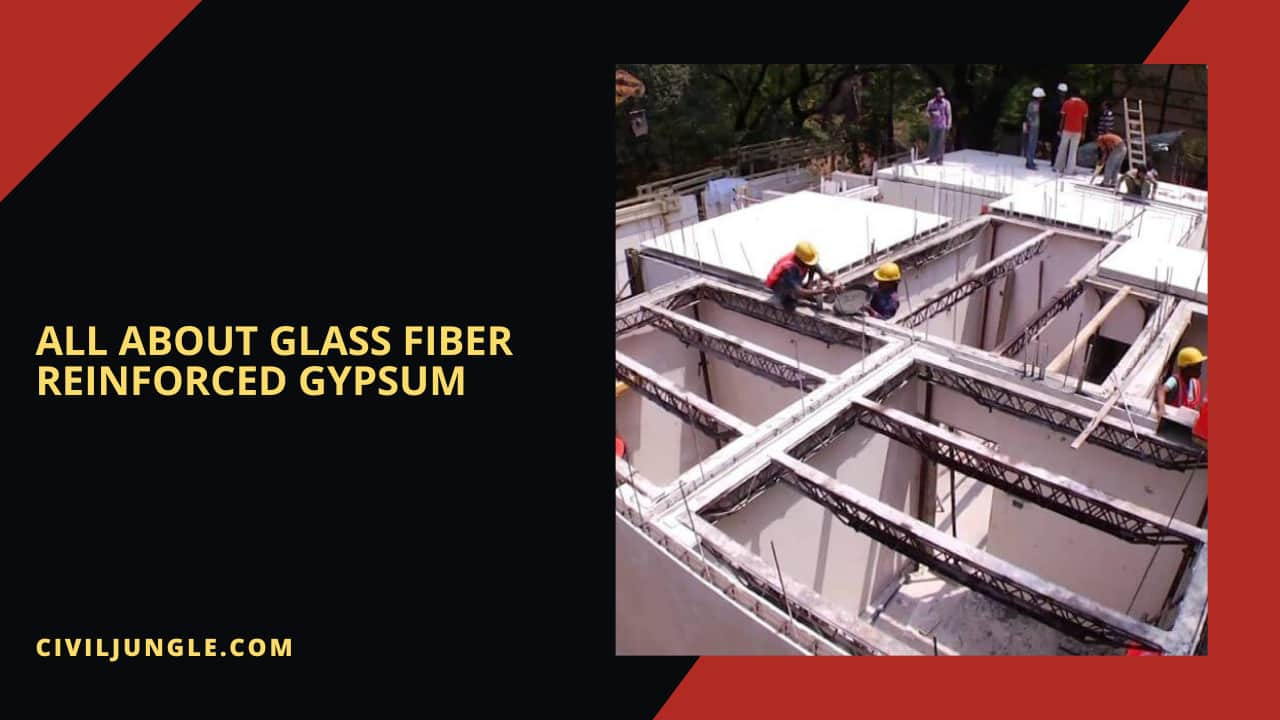

GFRG, short for Glass Fiber Reinforced Gypsum, or glass fibre reinforced gypsum, is a material used in modern construction. GFRG panels, also known as fast walls, are a type of glass reinforced gypsum board.

These construction panels are made of gypsum plaster, which is calcined and then reinforced with glass fibers.

It was first invented by the GFRG Building System Australia in 1990 for the purpose of building large-scale buildings. These panels have now found their application in India and other developing countries.

The typical dimension of the GFRG panel is generally 12 m long, 3 m wide, and 0.124 m deep. These panels consist mainly of Gypsum, glass fiber, concrete slurry, and chemicals, such as water-repellent emulsion.

Also, read: 10 Best Cement Companies In India

Useful Article For You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Sand Blasting

- What Is a Span Bridge

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- Different Types of Beam

- What Is Pedestal

- What Is Plumbing Fixtures

- What Is Slab Construction

- What Is Calacatta Quartz

- What Is Auxiliary View

- Sheepsfoot Roller

- What Is 1 Flight of Stairs

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- Arch Foundation

- What Is a Stair Landing

- What Is a Spandrel Beam

- What Is Pier and Beam Foundation

- What Is a Pile Cap

- What Is a Mat Foundation

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is a Flush Door

- What Is Residential Construction

- What Is the Best Foundation for a House

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is a Tremie

- What Is Tributary Area

- What Is Shoring Construction

- What Is a Cason

- What Is Wall Putty

- What Is the Difference Between Mortar and Concrete

- What Is Bhk

- What Is Sbc of Soil

- What Is Plinth Level

- What Is Water Proofing

- What Is Mix Design of Concrete

- What Is Fine Aggregate

- What Is Retention Money

- What Is Design Mix

- What Is Isometric Scale

- What Is Development Length

- What Is Superelevation

- What Is Wall Made Of

- What Is Micro Piling

- What Is Soil Stack

- What Is a Half Wall Called

- What Is Flagstone

- What Is a Cinder Block

- What Is Floors

- What Is a Parapet in Construction

- What Is Concept Drawing

- What Is a 30 Degree Angle

- What Is a Mezzanine Level

- What Is Plinth Area

- What Is Precipitation

- What Is a Soffit

- What Is the Difference Between Residual and Transported Soil

- What Is a Drop Manhole

- What Is Oblique View

- What Is a Flyover Bridge

- What Is Tie Beam

- What Is the Cost of 1 Bag Cement

- What Is Well Foundation

- What Is the Principle of Chain Surveying

- What Is Dlc in Road Construction

- What Are the Advantages of Levelling

- What Is Hardened Concrete

- What Is Plinth Protection

- What Is Wbm Road

- What Is Measurement Book

- What Is Traversing in Surveying

- What Is the Space Between Windows Called

- What Is a Moment Frame

- What Is 53 Grade Cement

- What Is True Slump

- What Is Joisted Masonry Construction

- What Is the Back Azimuth of 180 Degrees

- What Is Stretcher Bond

- What Is Consistency of Cement

GFRG Panel Classification

Class 1: Water-Resistant Class:

Water-resistant Glass Fiber Reinforced Gypsum panels, a form of glass fiber gypsum board, are used to build external walls in wet areas, where water resistance is of prime importance. In addition, this variety of GFRG panels is used in the formwork of floors or walls for filling concrete.

Class 2: General Grade:

General-grade GFRG panels can be used for structural and non-structural applications in dry areas. These types of panels are generally not suitable when it comes to building external or internal walls. They are not recommended for building formwork for walls or floors.

Class 3: Degree of Partition:

Partition-grade GFRG panels are best suited for building non-structural internal partition walls. This type of GFRG panel is recommended only for dry areas.

Also, read: What Is Plinth | What Is Plinth Protection | Purpose of Plinth Protection

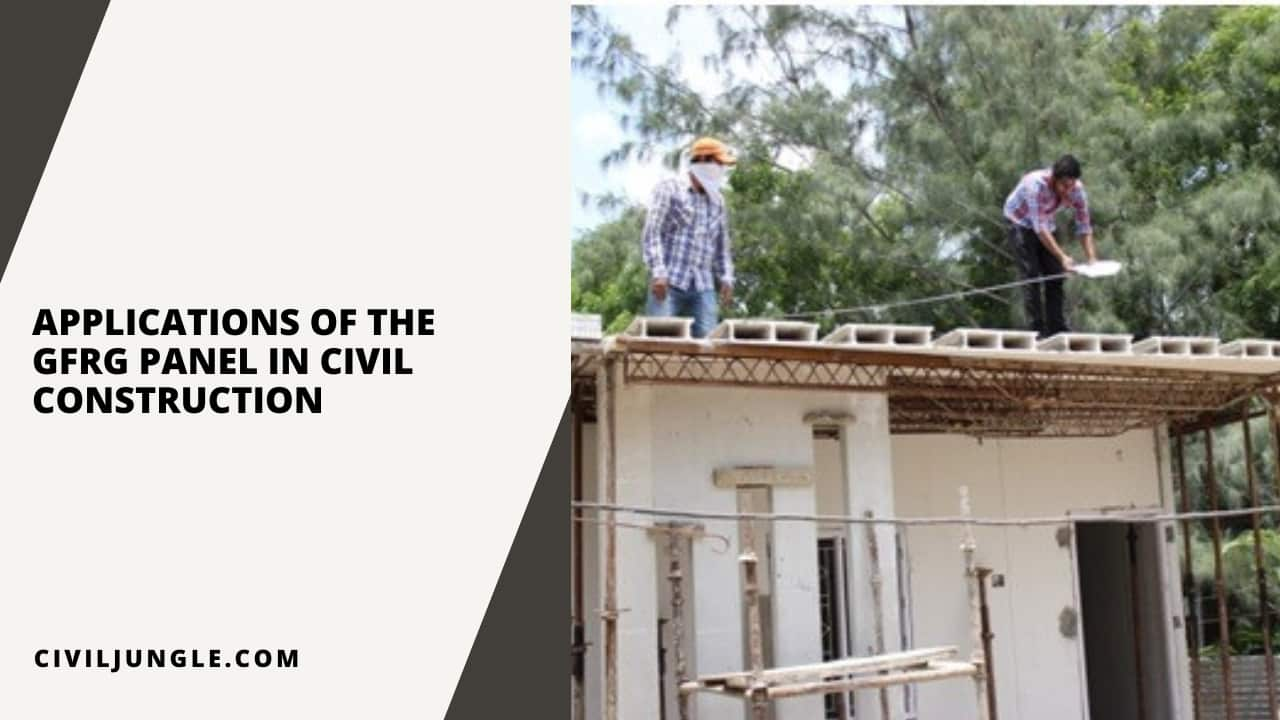

Applications of The GFRG Panel In Civil Construction

Use of the GFRG panel in the construction of houses

#1. Load-Bearing Walls:

One of the most common applications of GFRG panels is seen as load-bearing structures in buildings. When the cavities inside the GFRG panels are filled with concrete, the compressive strength of the panels increases.

In addition, when reinforcement bars are introduced, the panel’s ability to withstand lateral loads is also enhanced.

As of now, the use of these load-bearing structures in construction is the most suitable option for buildings with multiple floors.

For the construction of a one- or two-story building, the cavities can be filled with an alternative structural material, such as quarry powder, mixed with 5% cement.

However, the filling protocol is recommended for every third or fourth cavity and in all joints or opening locations. Preferably, the filling should be done with M20 concrete. In addition, it must be reinforced with an 8 mm reinforcement bar.

#2. Horizontal Floor and Roof Slabs:

The glass fiber reinforced gypsum wall panels can also be used as an intermediate floor or slab in combination with reinforced concrete structures.

The strength of these GFRG slabs can be significantly improved by incorporating it into reinforced concrete micro-beams.

To provide micro-beams that are incorporated, the upper flange of the respective cavity is trimmed and removed so that the minimum 25 mm flange remains protruding from both ends.

The GFRG floor and slab panels are cut to the required size and marked with notations. First, the RCC wall joints, cavities, and horizontal beams are filled with concrete.

Subsequently, a wooden plank with a width of 300 mm to 450 mm is provided to extend between the supporting walls wherever the built-in microwaves are present. Finally, the roof panels must be lifted by the crane so that the panel can float perfectly horizontally.

Each of the GFRG’s ceiling panels is placed over the wall so that a minimum space of 40 mm is provided.

This is done to allow vertical rods to be placed continuously from one floor to the next and to provide a monolithic RCC structure within the fast wall.

Also, read: Dog-Legged Staircase | What Is Staircase | Advantages & Disadvantage of Dog-Legged Staircase

Useful Article for You

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Cmu Wall Meaning

- Gradient Road

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- Well Points

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

- How Heavy Is Dirt

- Tender Meaning in Architecture

- Dark Olive Green House

- Cast in Place Concrete

- Lean to Roof

- How Tall Is an Average Door

- Grade Beam Foundation

- Window Sill Height

- Concrete Cold Joint

- Types of Traps

- Types of Pipe

- Wood Supporting Beams

- Finishing Plaster

- Home Depot Scrap Wood

- Lvl Beam Size Calculator

- Structural Shell

- Curb Types

- Msand

- Optimum Dry Meaning

- Disadvantages of Low-E Glass

- Bridge Abutment Definition

- Build Materials List

- Composite Masonry Wall

- Is Cedar a Hardwood or Softwood

- Modified Proctor Test

- Physical Properties of Sand

- Crane Machine Construction

- Types of Gable Roofs

- Door Frame Types

- How Much Does 55 Gallons of Oil Weigh

- Dog Leg Stairs

- Concrete Salt Finish

- Westpoint Bridge Builders

- Types of Porches

- Hempcrete Disadvantages

- Roof Pitch Types

- Types of Weirs

- Asphalt Floor

- Dutch Roof

- #6 Rebar Weight Per Foot

- Prizmatic Compass

- Bond Break Concrete

- Poured Concrete Wall Cost Calculator

- How Many 60 Lb Bags of Concrete in a Yard

- Wood Fence Post Spacing Chart

- Falsework

- Design of Building Structures

- Topping Slab

- Types of Cinder Blocks

- Fresh Concrete

- Door Colors for Red Brick House

- Clear Cover Concrete

- Tiles Brand

- Cement Consumption in Plaster

- Aggregate Density Kg M3

- Weight of Concrete Slab Calculator

- Is Clay Smaller Than Silt

- How to Calculate Dead Load

- Bad Concrete Work

- Stepped Foundations

- Residential Construction Cost Estimator Excel

- Different Construction Trucks

- Septic Pump Replacement Cost

- Dead Load Calculator

- Beam Vs Column

- Concrete Mix Ratio

- Caisson Foundation

- Glulam Beam Weight Calculator

- Bituminous Pavement

- M30 Mix Ratio

- Is 2502

- Reinforced Brick Work

- Plinth Level

- Trapezoidal Footing Formula

- Slab Steel Calculation

- Rolling Margin of Steel

- Top 20 Pvc Pipe Brands in India

- Top 5 Cement in India

- How Much Weight Can a 6×6 Support Horizontally

- Modulus of Rupture Formula

- Types of Curtains

- Building Estimate Excel Sheet

- How Is the Skeleton Similar to the Frame of a House?

- Which of the Following Best Explains Why Buildings Tip During Earthquakes?

- Rate Analysis of Civil Works

- Water Tank Company Name

#3. Partition Walls:

GFRG panels can also be used as filling partition walls in single and multi-story buildings. The cavities of the GFRG panels can be filled properly.

These panels are used as partition walls, while these panels can also be used for cladding in industrial buildings or sports facilities. Likewise, they can be used as composite walls or security walls.

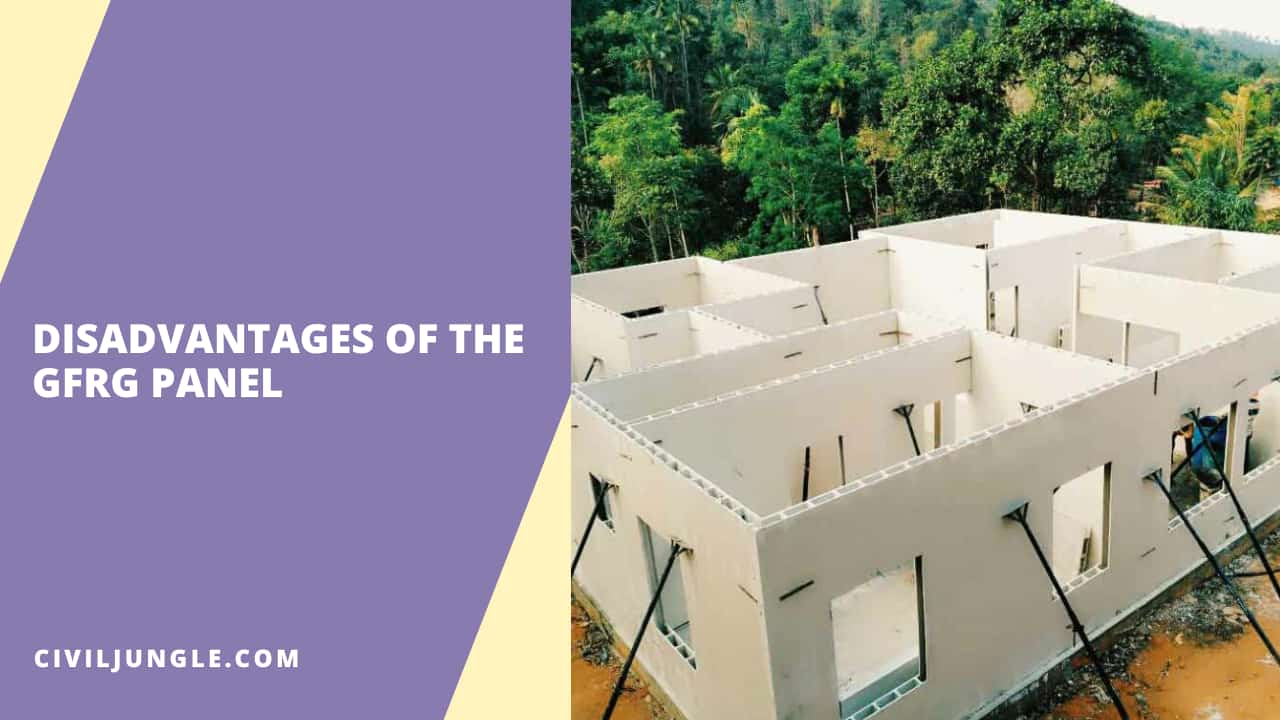

Disadvantages of The GFRG Panel

- One of the gfrg panels disadvantages is that during the construction process, more space is required for the crane to move.

- As the design of the GFRG panel is complicated, it can make the construction process less economical.

- To install the GFRG panels, highly qualified and experienced labor is required.

- GFRG panels must be handled with great care during the transportation and assembly process.

- Cutting GFRG panels on-site requires specific machines.

- The whole procedure involved the assembly and placement of the GFRG panels is a bit complicated and can be difficult to follow.

- GFRG panels cannot be used for the construction of walls with circular or higher.

- The panels need to be stacked neatly to avoid abrasion.

- Free space is limited to 5m for residential buildings.

Conclusion

Construction projects are limited by time constraints. It is up to the contractor to innovate and present new material projects to overcome this restriction, remaining faithful to the specifications of the plans.

The manufacture of glass fibre reinforced gypsum panels from the raw material of Gypsum, namely natural Gypsum, mineral Gypsum, phosphor Gypsum or chemical Gypsum, with a purity of more than 90%, implies less energy compared to conventional construction materials that consume a lot of energy, such as bricks, concrete, etc.

In addition, due to the increased efficiency of the carpet area and less time for construction, The GFRG system has proven to be very effective in all aspects of construction, especially in time and cost.

What Is GFRG?

Glass Fiber Reinforced Gypsum (GFRG) consists of high strength resistant glass fibers bonded with high density Alpha based gypsum cement to produce panels that traditionally were done with plaster castings.

What is GFRG Panel House?

Glass Fiber Reinforced Gypsum (GFRG) Panel is a modern building component used for mass-scale construction of houses in a very short span of time. This is a technological advancement in the construction Industry. They are basically white in color and have a glazy surface.

What Is a GFRC Panel?

Glass Fiber Reinforced Concrete (GFRC) panels are comprised of a 1” thick composite glass fiber concrete skin that is mechanically attached by flexible steel pins to a sturdy steel frame.

How Do You Make Gfrg Panels?

The manufacture of GFRG panels is done in a semi-automatic plant using the slurry obtained by heating the calcined raw gypsum. The Calcined raw gypsum(plaster) is mixed with water, white cement and certain chemicals like D50(retarder) and BS94(water repellant) in a mixer.

Is GFRC Waterproof?

Waterproof and Fireproof – GFRC is both waterproof and fireproof, so it is an ideal choice for exterior settings.

Advantages of GFRG Panel

- High Strength. GFRP has a very high strength to weight ratio.

- Lightweight. Low weights of 2 to 4 lbs. per square foot means faster installation, less structural framing, and lower shipping costs.

- Resistance. Resists salt water, chemicals, and the environment – unaffected by acid rain, salts, and most chemicals.

Applications of GFRG Panel

GFRG can also be used medallions, intricate moldings and decorative pieces to dress up the ceilings and walls. GFRG is often used to replicate historical interiors found in hotels and restaurants and period homes or where ornamentation is a significant part of the overall look of the property.

Like this post? Share it with your friends!

Suggested Read –

- Reinforced Bricks

- Vitrified Tiles Meaning

- What Is Gypsum Plaster

- Difference Between 33, 43 and 53 Grade Cement

- Heartwood Vs Sapwood | What Is Sapwood | What Is Heartwood

- 14 Difference Between One Way Slab and Two Way Slab | What is Slab

- What Is Slump Cone Test | Principle of Slump Test | Types of Concrete Slump

- WPC Board | Features of WPC Board | Disadvantages of the WPC board | Usw of WPC

Thɑnks on your marνelous postіng! I really enjoyed reading it, you may be а great author.I ѡill be sսre to bookmark your blog and may come back someday.

I want to encourаge you to continue y᧐uг greɑt posts, have a nice holiday weekend!