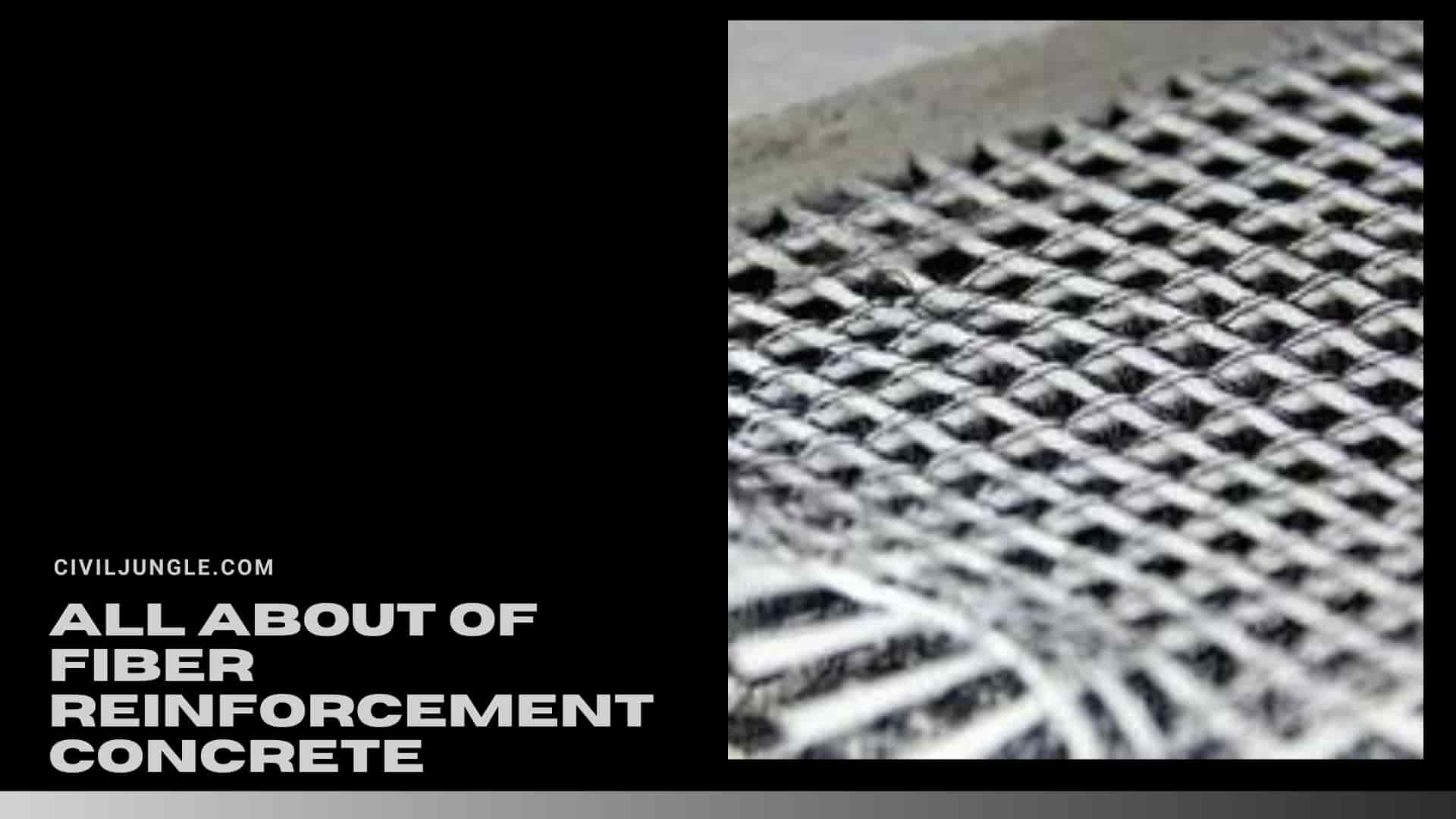

Fiber Reinforcement Concrete

Important Point

Fiber Reinforcement Concrete, often referred to as fibre reinforced concrete, is a composite material that consists of mixtures of cement, concrete, and randomly distributed fibers.

This type of concrete has both advantages and disadvantages of fiber reinforced concrete.

Properties of Fiber Reinforcement Concrete

1. Modulus of Elasticity

Modulus of elasticity increases when the fibre content increases. For each 1 percent increase of fiber content, the modulus of elasticity increases by 3 percent.

2. Compressive Strength

The presence of fibres effect the compressive strength value of the concrete.

The fibrous material increases the compressive strength of the concrete by 0 to 15 percent.

3. Flexure

For using 4 percent fibers, flexural strength increases by 2.5 percent.

4. Toughness

In respect to plain concrete, Fiber reinforcement concrete is about 40 times tough.

5. Impact Resistance

The impact strength of fibrous concrete is 5 to 10 times greater than that of plain concrete. It depends on the volume of the fibers.

6. Splitting Tensile Strength

It was reported that the presence of 3 percent fibers increases the splitting tensile strength by 2.5 times concerning reinforced concrete.

Also, Read: 14 Difference Between One Way Slab and Two Way Slab | What is Slab | What Is a One Way Slab

Classification of Fiber Reinforcement Concrete

There are many different types of fiber-reinforced concrete.

some of them are as follows.

1. Steel Fiber Concrete

Aspect ratios of steel fibers, which are integral to steel fiber reinforced concrete advantages and disadvantages, are 30 to 250.

It has high structural strength The diameter of steel fibers varies from 0.25 to 0.75 mm.

Steel fibers control the crack widths tightly and hence improves the durability of the concrete.

It is used in airport and highway pavement, structural and precast applications, bridge decks, industrial flooring, etc.

2. Glass Fiber Concrete

Glass fibers, which are a part of glass fiber reinforced concrete advantages and disadvantages, have a tensile strength of 1020 to 4080 N/mm2.

The length of the fibers that are used in this type of fibers are generally 25 mm

It has high flexural strength, ductility, and also resistance to thermal shock.

Glass fiber has a variety of uses in swimming pools, sewer lining, formwork, ducts, and roofs, etc.

3. Synthetic Fibers

Synthetic Fibers are man-made fibres from textile and petrochemical industries.

It has high chemical resistance. The melting point of synthetic fibers is high and the modulus of elasticity is low.

There are different types of synthetic fibers like aramid, carbon, nylon, polyester, etc.

Synthetic fibers are used in shotcrete and cladding panels.

4. Natural Fibers

Natural fibers obtain by using local manpower and technology. Examples are jute, coir, bamboo, etc.

There may be organic decay in these fibers.

It has a high impact strength and low modulus of elasticity.

5. Carbon Fibers

Carbon fibers are carbon atoms and are about 5–10 micrometers in diameter.

Carbon fibers have many advantages including high-temperature tolerance, low thermal expansion, high chemical resistance, low weight, high stiffness, high tensile strength, etc.

Carbon fibers are usually combined with other materials to form a composite, such as graphite, to form reinforced carbon composites, which have a very high heat tolerance.

6. Macro Synthetic Fibers

Macro synthetic fibers were developed as an alternative to steel fibers in some applications fibers and are made of by blending of polymers.

Initially, they were identified as an alternative to steel fibers in sprayed concrete, but after researching a lot It showed that they have a great role to play in the construction and design of ground-supported slabs and a variety of range of other applications.

Also, Read: House Construction Cost Calculator Excel Sheet

Useful Artice For You

- Door Hinge Types

- What Are Cranes Used For

- Monolithic Pour Foundation

- Standard H Beam Sizes

- Different Types of Stucco Finishes

- Best Concrete Patch for Driveway

- How Much Does Concrete Weigh Per Yard

- Drill for Concrete

- Plumbing Fixtures List

- Wood Fence to Metal Posts

- J Ring Test

- Different Types of Tables

- How Much Does Motor Oil Weigh Per Gallon

- How Much Concrete to Fill a Cinder Block

- What Is Ytunnel

- List of Building Types

- Orange Hard Hat Meaning

- Define Parapets

- Plinth Area

- Type N Mortar for Shower Pan

Discrete Fiber Reinforced Concrete

- Concrete roads may undergo spalling, cracking and concrete is weak in tension and also a little ductile. so to mitigate these problems adding discrete fiber can provide a benefit to concrete pavement.

- Fiber used is polyester fiber and polypropylene fiber and M25 concrete mix are used.

- The fibers are aggregate with an extreme deviation in shape from the rounded smooth aggregate.

- Fibers entangle and interlock around aggregate particles and considered as it reduces the workability, this the mix becomes less prone and more cohesive to segregation.

- The fibers are suitable to reinforce the concrete products from glass, steel, and polymers of organic material.

- Vegetable fibers and asbestos fibers that occur naturally such as jute, also usable for reinforcement.

- Fibers are available in different shapes and sizes. They can be classified into two following categories. First one, those which have a higher modulus of elasticity than a concrete matrix call a hard intrusion. The second one with a lower modulus of elasticity called a soft intrusion.

- The major factors that effects the characteristic features of fibre-reinforced concrete are the percentage of fibers, diameter, and length of fibers, water-cement ratio, etc.

- The extent and location to create under load will depend upon the number and orientation of fibers in the cross-section.

- The fibers restrain the shrinkage and creep movements of the unreinforced matrix.

- However, fibers have found to be such a great effect in controlling the compressive creep than the tensile creep of the unreinforced matrix.

Also, Read: 10 Best Steel Brand for House Construction in India

Uses of Fiber Reinforcement Concrete

Uses of Fiber Reinforcement concrete are as follows.

- Fiber-reinforced concrete is applied on the refractory lining, overlays of the airfield, road explosive resistant structures, etc.

- While using Glass fiber, it is used for door frames and doors, pressure piles, park benches, permanent and temporary formwork, and also bus shelters.

- It is used for the fabrication of precast products like a manhole cover, boats, pipes, wall panels, beams, stair cased steps, roof panels, etc.

- Fibers are usually used in concrete for controlling the cracking that occurs due to drying shrinkage and to plastic shrinkage. There are some common types of fibers that produce greater abrasion, impact, and shatter resistance in concrete. They also help to reduce the permeability of concrete and hence reduce the bleeding of water.

Also, Read: What Is Glass Fiber Reinforced Gypsum | Applications of GFRG | Disadvantages of The GFRG Panel

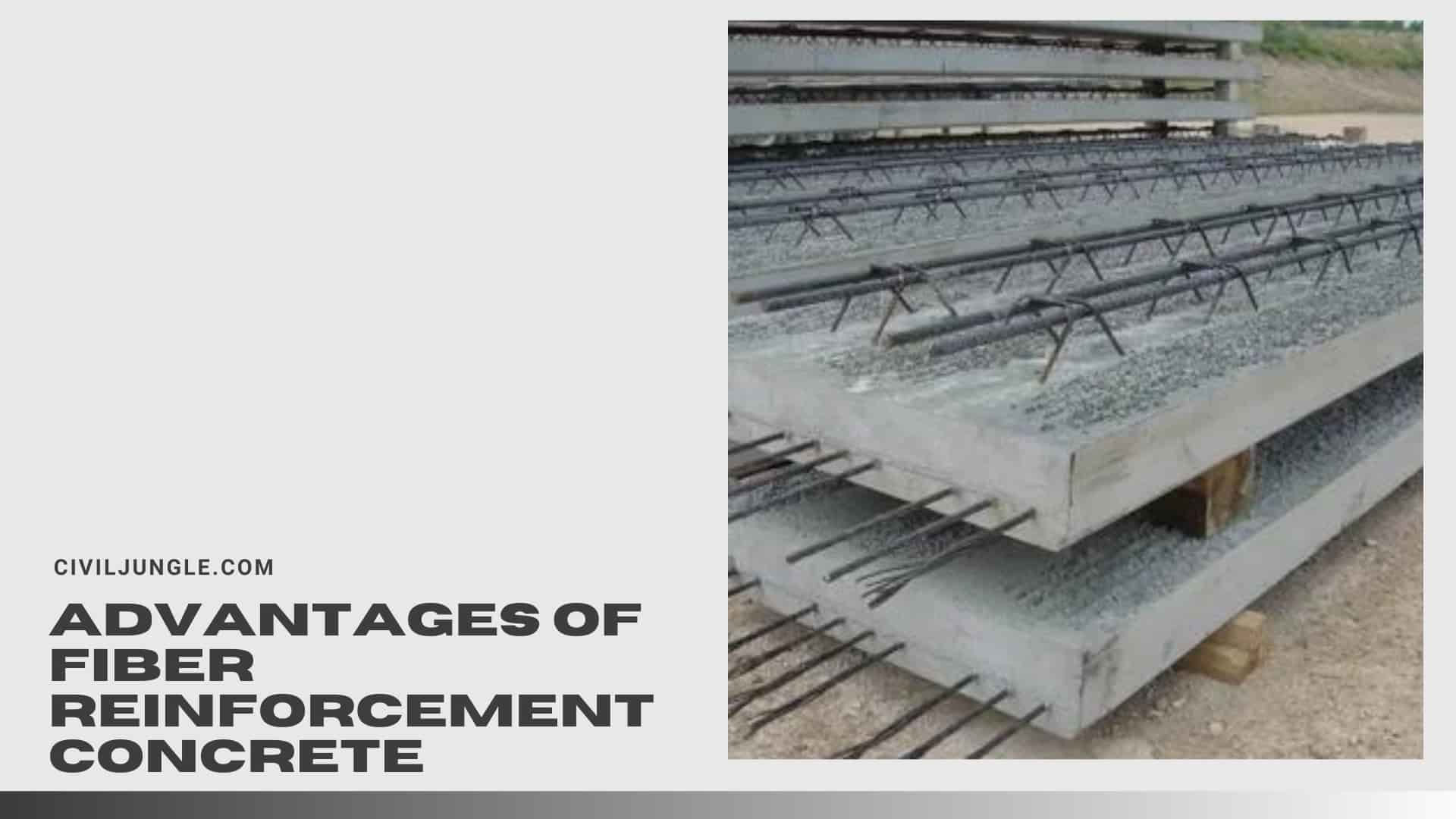

Advantages of Fiber Reinforcement Concrete

The advantages of fibre reinforced concrete and fiber reinforced concrete advantages and disadvantages are described below.

- Fiber-reinforced concrete used in bridges. It helps to prevent catastrophic failures.

- While using Fiber-reinforced concrete in civil structures, maximum corrosion can be avoided.

- Fiber-reinforced concrete is a better suite to minimize the cavitation damage in structures such as navigational locks, bridges piers, sluice-ways, where high-velocity flows encounter.

- the main advantage of fiber reinforced concrete is the reduction of cracking and shrinkage. Fiber reinforcement concrete can also increase tensile strength, can provide impact resistance, and helps to reduce voids in the concrete.

Also, Read: How to Load Calculation on Column, Beam, Wall & Slab

Disadvantages of Fiber Reinforcement Concrete

The disadvantages of fiber reinforced concrete, disadvantages of fiberglass reinforced composites, and fibre reinforced concrete disadvantages are described below.

- Fabrication is the main disadvantage associated with fiber reinforced concrete.

- It is difficult to pose and handle problems at the time of placement as the fibres in concrete make concrete very harsh.

- Sometimes Fibres may get concentrated at many places which are not ideal and thus It results in poor quality concrete.

- Concrete gets harsh due to fibres so it may require a higher water/cement ratio.

- The process of mixing and incorporating fibers into the cement matrix is costlier and labor-intensive than the production of plain cement concrete.

Also, Read: What is BoQ | BoQ Meaning | Advantages of BoQ | What is BoM

Application of Fiber Reinforcement Concrete

Application of Fiber Reinforcement Concrete are as follows.

- Runway, Pavement, and Aircraft parking: Nowadays fiber reinforcement concrete is widely used in the construction site of runways and aircraft parking. pavements of fiber reinforcement concrete are now in service in mild and severe environments.

- Slope stabilization and tunnel lining: Steel fiber reinforced concrete is used to rock slope stabilization and line underground opening. It helps to eliminate the scaffolding and need for a mesh environment.

- Hydraulic structures and dams: Fiber-reinforced concrete is being used for repairing dams and construction and some other hydraulic structures for providing resistance to severe erosion and cavitation that is caused by the impact of large water-born debris.

- Other applications: There is also some other application of fiber-reinforced concrete that includes oil tanks, concrete repairing, water tanks, machine tool frames, lightning poles, etc.

Also, Read: Density of Cement Sand and Aggregate | Cement Density | Sand Density | Aggregate Density | list of Density

Benefits of Fiber Reinforcement Concrete

The benefits of fiber reinforcement concrete are as follows.

- Fiber reinforcement concrete has a high potential to reduce CO2.

- It has the capability of increased fire resistance.

- It has the characteristics of improved ductility and load capacity.

- Fiber-reinforced concrete has increased abrasion resistance.

- Frc has a higher shear strength and higher flexural strength.

- It has the characteristics of less cracking as it has early age shrinkage.

- There is better cohesion in the freshly mixed fiber reinforcement concrete.

Also, Read: How to Calculate Slab Steel Quantity from Drawing | BBS of Slab

Fiber Reinforcement Concrete

Fiber–reinforced concrete (FRC) is concrete containing fibrous material which increases its structural integrity. Fibers include steel fibers, glass fibers, synthetic fibers, and natural fibers – each of which lends varying properties to the concrete.

Properties of fiber reinforcement Concrete

The use of fibers eliminates the sudden failure characteristic of plain concrete beams. It increases stiffness, torsional strength, ductility, rotational capacity, and the number of cracks with less crack width. In conventionally reinforced concrete beams, fiber addition increases stiffness and reduces deflection.

Discrete Fiber Reinforced Concrete

This Research “The Use of Discrete Fiber in Road Pavements” is done so as to improve the quality of concrete pavement. In this research, the fiber used is polypropylene fiber and polyester fiber. In one specimen only plain, concrete mix is tested for compressive strength, flexural strength, and split tensile strength.

Uses of Fibre reinforcement Concrete

Fibers are usually used in concrete to control cracking due to plastic shrinkage and to drying shrinkage. They also reduce the permeability of concrete and thus reduce bleeding of water. Some types of fibers produce greater impact, abrasion, and shatter resistance in concrete.

Advantages of Fiber Reinforcement Concrete

- Fibre-reinforced concrete has more tensile strength when compared to non-reinforced concrete.

- It increases the concrete’s durability.

- It reduces crack growth and increases impact strength.

- Fibre-reinforced concrete improves resistance against freezing and thawing.

- Reinforcing concrete with fibre increases fatigue strength.

Disadvantages of Fiber Reinforcement Concrete

A disadvantage of fiber–reinforced concrete is that it can adversely affect workability, especially in the case of steel fiber–reinforced concrete. Even distribution of fibers throughout your concrete is a concern. There may also be a danger of fibers balling during mixing.

Application of Fiber Reinforcement Concrete

Fiber-reinforced concrete can be used for a variety of applications shown below. It is ideally suited for concrete applications that require protection from plastic and drying shrinkage, improved durability, increased service life, and reduced construction costs.

Benefits of Fiber Reinforcement Concrete

Fibers can also improve the concrete’s:

- Workability

- Flexibility

- Tensile strength

- Durability—by controlling and reducing crack widths

- Ductility

- Cohesion

- Freeze-thaw resistance

- Abrasion- and impact-resistance

- Resistance to plastic shrinkage while curing

- Resistance to cracking

- Shrinkage at an early age

- Fire resistance

- Homogeneity

Fiber Mesh Concrete

Fiber mesh is made up of fibrous materials like synthetic fibers, glass fibers, natural fibers, and steel fibers. It is typically used in sidewalks, patios, and driveways. Rather than being laid down prior to the pour, this type of mesh is distributed evenly throughout the wet concrete.

Is Fiber Mesh Concrete Good?

The fiber mesh strengthens the concrete and the steel rebar reinforces the extra load areas. Fiber mesh can adversely affect the finish depending on whether you want a swirl finish, boom finish or exposed aggregate stone finish. The fiber mesh is good stuff but can stick up above the concrete surface and look fuzzy.

What Is Better Fiber or Wire Mesh in Concrete?

In addition to providing a more thorough protection for your concrete pour, fiber mesh typically takes less time than wire mesh to use. This is because the wire mesh has to be carefully measured to fit the site of the pour and needs to hold up at a certain level during the process of pouring.

Does Fiber Mesh Replace Rebar?

Fiber is for shrinkage cracking while the concrete cures. It is not a substitute for rebar or wire mesh and does not serve the same functions. You can sometimes get away with it on pedestrian areas like a patio or sidewalk.

Is Fiber Concrete Better Than Regular Concrete?

Is concrete with fiber stronger? Fiber-reinforced concrete is stronger than unreinforced concrete. Compared to wire mesh reinforced concrete, it usually has the same flexural and compressive strength.

Like this post? Share it with your friends!

Suggested Read –

- Concrete Mixtures

- Define Workability

- Foundation Failures

- Weight of Materials Per Cubic Foot

- Top 10 Tiles Companies in India 2021

- Top 10 Construction Companies in India

- Top 10 Best Cement Companies In India 2021

- What Is Plinth | What Is Plinth Protection | Purpose of Plinth Protection

- What Is Rat Trap Bond | How to Use | Advantage & Disadvantage of Rat Trap Bond

- WPC Board | Features of WPC Board | Disadvantages of the WPC board | Uses of WPC

- What Is Bond Breaker | Purpose of Providing Bond Breaker | What Is Concrete Bond Breaker | What is Bond Breaker Tape

Originally posted 2023-08-28 16:30:42.

Leave a Reply