What Is Spalling of Concrete?

Important Point

This phenomenon is also understood as spalling of concrete meaning in hindi in certain regions.

Spalling may be either localized and widespread depending upon the fire and concrete condition, particularly moisture content, and the susceptibility to the break-up of heat-unstable aggregate particles.

Also, read: What Is Honeycomb In Concrete | Cause | Cure | Type of Grouting

Causes of Spalling in Concrete

- On prolonged heating areas of concrete cover may also fall away, a process that is sometimes called ‘sloughing.’ This often leads to concrete spalling repair cost considerations.

- The processes causing sloughing aren’t generally reported, although it is noted that it occurs from corners of beams and slabs and seems to spread along a plane of weakness parallel to the outer surface.

- Because ‘sloughing‘ occurs late in a fire exposure, it is considered by some as being of less concern than explosive spalling that occurs earlier upon exposure to fire.

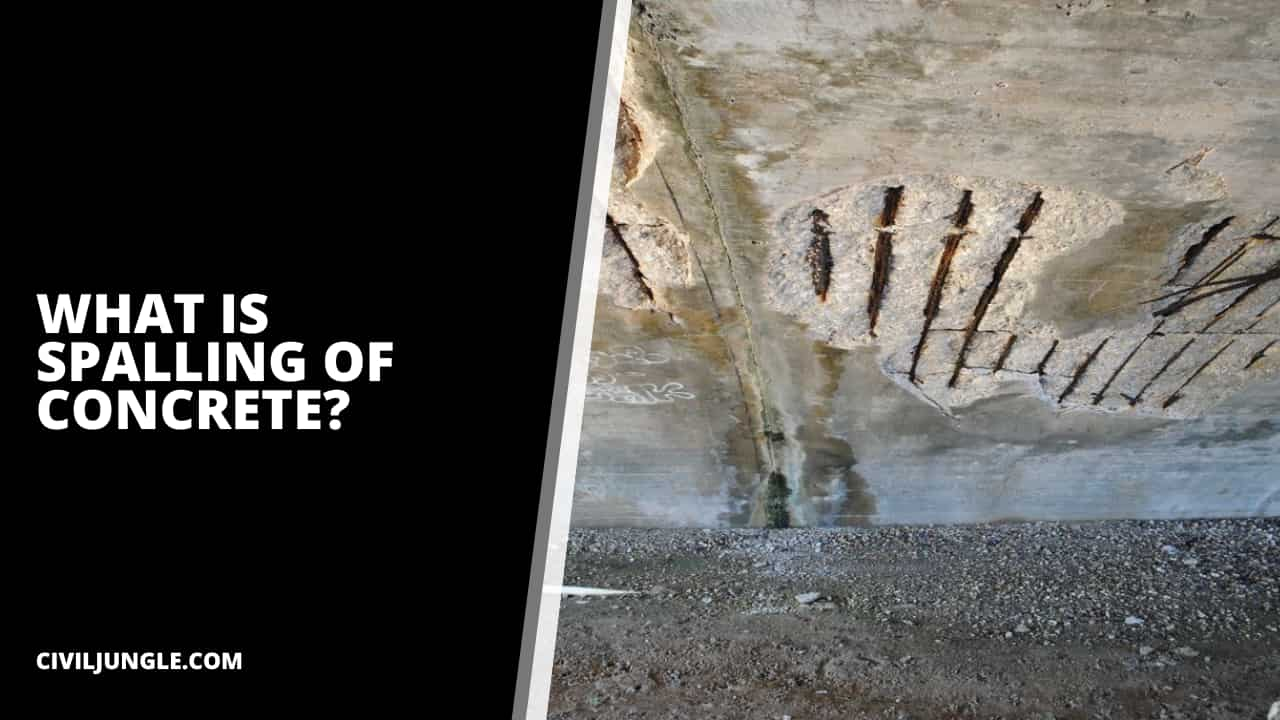

- Understanding explosive spalling, or spalled concrete meaning, is important because of the potential for loss in the section of the concrete element, the depth of fire-affected concrete, and the reduced protection to embedded steel. This often necessitates concrete spalling repair.

- Spalling is a frequently observed phenomenon in a fire, more prominently on soffits of slabs and on beams because of the greater exposure to heat and possibly heat ‘entrapment.’

- It is not certain that this frequent observation is fully anticipated by design codes, and this is discussed in more detail below in the section on design codes.

- The prediction of risk of concrete spalling meaning or occurrence, including issues like concrete driveway spalling, has not proven easy despite considerable research. The propensity to spall is influenced by the moisture content of the concrete.

- The permeability of the concrete, the rate of heating, the nature of the aggregate, and the load applied to the concrete.

- Although these separate contributing mechanisms have been identified, their relative contribution and their interaction are less well understood.

- There are, however, general trends that can be established. Concretes in a moist or saturated condition will spall faster and, more extensively, the drier the concrete.

- Some guidance (Malhotra, 1984; Concrete Society, 1998) suggests that moisture contents greater than 3% by weight will lead to spalling, although this ‘limiting’ value may be affected by the permeability of the concrete; the lower the permeability, the higher the risk of spalling, a higher temperature also increases the risk.

- Some research also shows that elements under higher structural load during the fire have increased risk of spalling. These issues are discussed in greater detail in the following sections.

Also, read: Why Is Polymer Mortar/Concrete | Type of Polymer Mortar/Concrete

Useful Article for You

- What Is Composite Wood

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- What Is Rebar Made Of

- What Is Crane

- What Is a Frame Structure

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is Mdf Mean

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Window Sash

- What Is a Sieve Analysis

- What Is the Little Black Diamond on a Tape Measure

- What Is the Difference Between a Bolt and a Screw?

- What Is Overhang

- What Is a Contour Interva

- What Is a Spread Footing

- What Is a Pitched Roof

- What Is Tile

- What Is Leveling

- What Is Modulus of Rupture

- What Is a Caisson

- What Is a False Ceiling

- What Is the Lightest Weight Wood

- What Is Sandblasting

Measures to Prevent Concrete Spalling

- In a concrete floor slab, Early-entry dry-cut helps prevent spalling, which is defined as concrete spalling definition in spalding definition construction terms.

- Apply good water to the finished surface to prevent water from entering into a concrete.

- Prevent excess water at concrete mixture since it leads to a concrete spalling.

- Proper working management of concrete during pouring to ensure a provision of adequate cover and placement of joints at correct positions.

Useful Article For You

- Types of Doors

- What Is a Contour Interval

- Parapet Wall

- How Much Does 1 Gallon of Water Weigh

- Flight of Stairs

- Sheeps Foot Roller

- Queen Size Bed Dimensions in Feet

- Moment Frame

- Edm Instrument

- Monolithic Slab

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Live Load Vs Dead Load

- Cmu Wall Meaning

- Gradient Road

- Pile-Cap

- Bond Breaker

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- Concrete Cold Joint

- Well Points

- Abutment Bridge

- Finishing Plaster

- Spandrel Beam

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

Repairing Concrete Spalding

The solution to this may require that less labor-intensive repairs be done.

Here are some of the ideas you could use to Repairing a spalled concrete.

- Once you notice a damaged concrete, if it’s less than 1/3 of its thickness, the repair could be done. But when it’s deeper, you might install a steel bar and might require a full restoration.

- When the rebar is exposed or corroded, it should be cleaned before it’s restored. Use a wire brush to clean the steel bar surface very well before you apply a protective coating. It could help to stop or prevent this.

- Once the problem is on the horizontal surface or within the driveway, plaza, or like sidewalks, you might need to apply a cement overlay. Once the overlay set is completed, the waterproofing membrane could be applied to stop also prevent concrete spalling.

- To carry out the successful repair, ensure that you remove a concrete near about 1.5 inches (35mm) deep. You should then clean and remove all debris before the repair commences.

- You can do that patching, so they extend 4″ beyond the area affected by concrete spalling.

- If you want to get better results, cut a rectangular part of the concrete so that the patching may be done also get the concrete contained within the specified area.

- Remove and clean all debris and ensure that all particles are removed. It might be cleaned with water, but the excess water should be removed with a sponge. The surface must dry up before the compound is applied.

- The old surface could be rough so as to allow for better bonding inside a new concrete.

- The best patching materials include epoxy also Portland cement.

- The patch material should be mixed very well, but you should consider that they may react or mix with what you want to use within 15 minutes.

- Ensure that the air temp. is above 40 degrees Fahrenheit if you want the patching to work well.

- Ensure you only use materials that have a similar expansion coefficient with that of the existing concrete.

- Before the joint is repaired, ensure it is restored properly so as to give some allowance for the expansion of the slab.

Spalling of Concrete

Spalling concrete is a common problem where part of the surface peels, breaks or chips away. Also known as scaling, it is the result of a weak surface that is susceptible to damage. Spalled concrete may be caused by any of the following: Freeze-thaw cycles. A bad concrete mix.

How to Repair Spalling Concrete?

- Clean Spalled Concrete Area

- Remove Loose Concrete

- Clean and Coating Corroded Steel Bars

- Apply Repair Material Mixture

- Finishing

- Curing

- Apply Pain or Coat on Repaired Surface

Foundation Spalling Repair

Remove the spalled concrete to remove all dirt and loose surface. Treat any reinforced steel to prevent it from rusting. Saturate the concrete with bonding agent before applying mortar and brush finish to match existing concrete. Cover the concrete with a damp cloth or keep a sprinkler on for a few days, so it doesn’t dry out too fast.

If the damage is severe, a structural engineer will have to replace the affected wall. Contact Done Right Foundation Repair to get a professional inspection of your foundation and viable solution.

Foundation Spalling

Foundation spalling is the crumbling of the surface concrete that usually occurs on your crawl space or basement walls, but it can also happen on your concrete slab. Spalling concrete often looks like crumbling or flaking on your foundation’s surface and is most apparent on the interior of your foundation walls or floor.

Spalling Concrete Repair Cost

Concrete resurfacing resolves spalling issues and costs an average of $2.50 to $4.00 per square foot with a range of $250 to $400 for a 100 square foot area.

Spalling Concrete Foundation Repair

Remove the spalled concrete to remove all dirt and loose surface. Treat any reinforced steel to prevent it from rusting. Saturate the concrete with bonding agent before applying mortar and brush finish to match existing concrete.

Spalling Concrete Foundation

Spalling is the deterioration of the concrete or masonry around your home as a result of water entering into brick, concrete or natural stone and cause the foundation to push outward, flake and peel.

Concrete Surface Spalling

Spalling is the flaking or peeling away of small particles of cement paste from the near-surface portion of the finished slab. Finished concrete is often porous and can absorb rain water. Spalling occurs on exterior slabs when water that is trapped in the concrete goes through multiple freezes and thaws.

Spalling Garage Floor

Spalling is generally caused from cold winter climates that subject the concrete to freeze thaw cycles. What happens is water is deposited on the garage floor and works its way into the capillaries of the concrete. When the water freezes, it expands and causes microscopic damage to the surrounding concrete.

Spalling Concrete Driveway

If your driveway surface has spalling concrete, the most likely cause is an installation mistake. Common mistakes include adding too much water to the mix, to make it easier to pour; sprinkling the surface of the concrete with water, to extend finishing time; and not curing the concrete properly after installation.

Like this post? Share it with your friends!

Suggested Read-

- Strong Concrete Mixture

- Top 15+ Best Plywood Brands in India

- Top 10 Construction Companies in the USA

- Definition Efflorescence | Efflorescence in Concrete

- 10 Best Steel Brand for House Construction in India

- What Is Cover in Concrete | Clear Cover in Beams, Slab, Column, Footing

- What Is Workability of Concrete | Factors Affecting Workability | Test |Errors

- Concrete Mix Ratio | What Is Concrete Mix Ratio | Type of Concrete Mix Ratio

- What Is Contour Interval | Calculation of Contour Intervals | Uses of Contour Intervals in Surveying

Originally posted 2023-09-04 13:00:47.

Very Good article, our company is work for the concrete laser screed machine. The website is laser screed. Colud you help us write a aricle like that?

Many thanks!

Thanks

Thank you very much for sharing about spalling concrete here… I really hope I can work on your tips and it works for me too, I am happy to come across your article. Great post I must admit, keep sharing more…