Reamed Meaning

Important Point

Reamed is a cutting procedure for which a cutting process creates a very precise hole size.

What Is Under-Reamed Pile Foundation?

The Under-Reamed Piles Foundation is a response in areas whereby black cotton soil might eventually cause structural instability. In most instances, soils experience volumetric variations due to fluctuations in moisture below surface of the soil.

Such expansion as well as shrinkage will cause discomfort, which is quite risky and vital to the bearing of the base. The implication that under Reamed Piles is known to be the safest and most affordable base for certain black cotton soils or expansive soils.

Also, Read: Difference Between Short Column and Long Column | What Is Column | Types of Column

Development History of Under-Reamed Pile

The issue of a defect to the composition of the expansive soil is global. Such soils were accessible across all regions. Owing to this, there has been substantial disruption to the built properties. The disruption to the buildings is primarily due to the expansion and contraction of the soil.

Under-Reamed Piles are being extensively tested by the Central Building Research Institute (CBRI), Roorkee, to be used in black cotton soils which tend to provide a more outstanding response to the rooting problems in expansive soils.

Definition of Under-Reamed Pile

A cast-in-situ concrete pile with such a widened bulb at the bottom, rendered either through cutting or scooping out all the soil or through other appropriate methods, is considered the Under-Reamed Pile. Under-Reamed Piles are often referred to as bored cast-in-situ concrete piles.

A pile built mostly in the field to transfer the load of the foundation to the soil by resistance produced as in its tip along the top, or even both, is referred to as bearing piles.

When the piles are predominantly provided by resistance formed at the point or base of the pile, they are related to it as the “End-Bearing Pile” and even if the load is mostly assisted by friction along its top, the pile is related to it as the Friction Pile. When this is intended primarily to avoid uplifting or pulling, it’s considered an “Anchor Pile.”

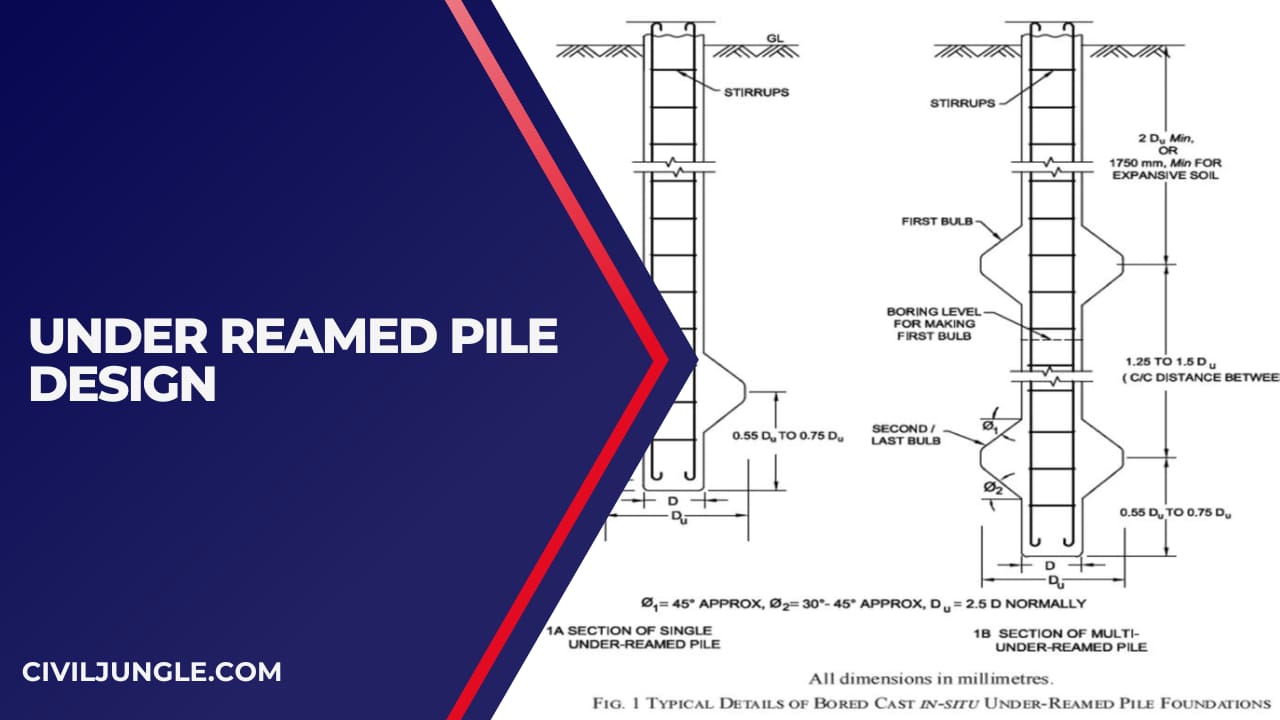

Under Reamed Pile Design

- The concrete used during under-ream piles should have such a slump of 10-15 cm for concrete in water-free unlined holes drilled. For concrete formwork, the concrete required must have a slump of 15-20 cm with efficient outcomes. M-15 or M-20 concrete with a minimal cement content of 350 or 400 kg/m3 can also be used.

- The minimum length of under-ream piles in dense layers of expansive soils ought to be 3.5 m below the surface level.

- The diameter of the substrate is holding 2.5 times the diameter of the stem.

- The overall vertical spacing here between under-reams is 1.5 times the depth of the under-reams for piles up to 0.3 m in diameter. In large diameter stacks, the spacing can be decreased to 1.25 times the diameter of the stem.

- The maximum bulb will be at a minimum size of twice the diameter of the bulb. In the case of vast soils, this depth should never be below 1.75 m ground level.

- Generally, the amount of bulbs issued does not exceed 2.

- The minimum central distance of the under-ream piles in a group is 1.5 times the diameter of the under-ream and is normally maintained at double the under-ream diameter.

- Throughout the case of a pile group with a pile spacing of 2 Du, the size of the group can be assumed to be equal to the amount of the load-carrying strength of the specific piles in the category. Throughout the case of a pile group with such a 1.5 Du pile spacing, the safer load allocated per pile should really be decreased by 10%.

Also, Read: H-Beam vs I-Beam | What Is H-Beam | What Is I-Beam

Increasing Load-Carrying Capacity of Under Reamed Piles:

- By putting more bulbs

- By increasing the dia. of the bulb

- By increasing the length of the pile

- By providing proper reinforcement

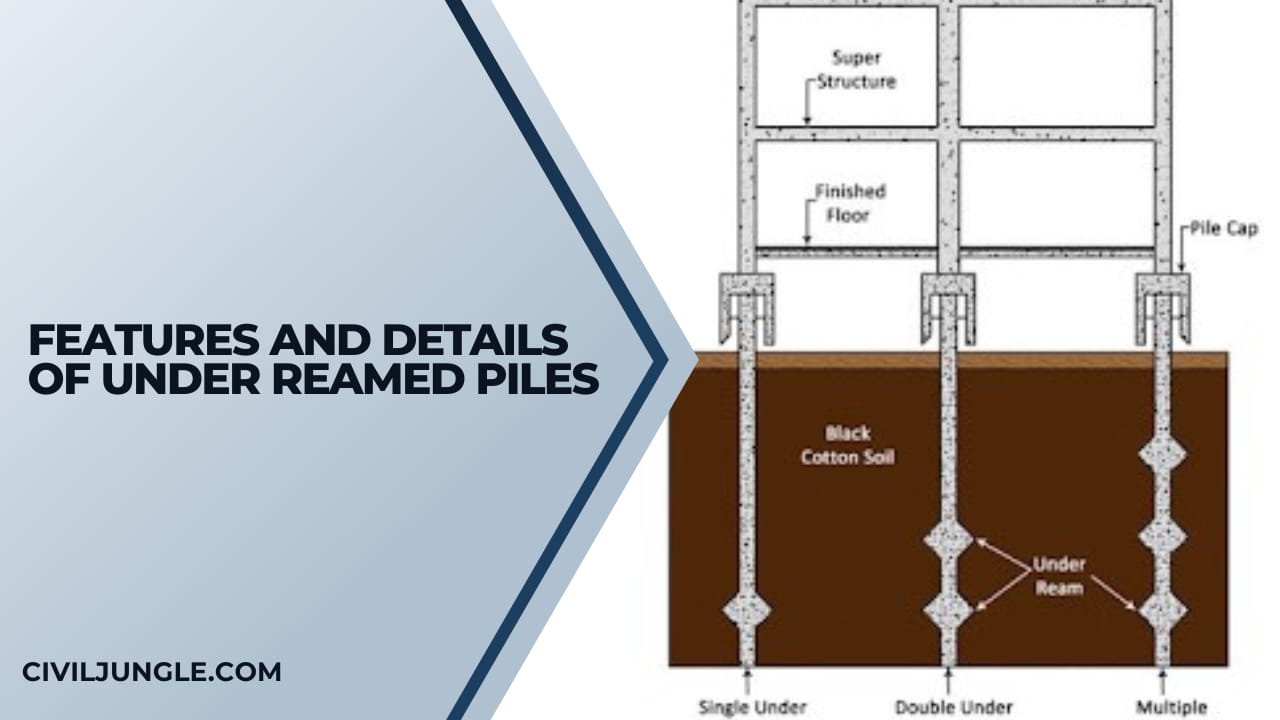

Features and Details of Under Reamed Piles

- Pile Diameter = 20 cm to 50 cm

- Bulb Diameter = two to three times the diameter

- Pile Length: 3 m to 8m

- Space between two piles = 2 – 4 m

- Spacing between Two bulbs = 1.25 – 1.5 times the bulb diameter.

- Load-carrying capacity = 20 to 40 tonnes

Those are all drilled cast-in-situ concrete piles which have one or even more bulbs shaped toward its base by expanding the borehole of the pile stem. Enlargements aid in including significant bearings or anchorages. These piles are being proven to be helpful in expansive soils including such black cotton soil, as bulbs offer uplifting anchorage owing to swollen pressure.

The diameter of the bulbs under reamed bulbs maybe two to three times the diameter of the stem. The spacing of the bulbs is 1.25 – 1.5 times the diameter of the stem. The uppermost bulbs must be at a sufficient depth of 2 times the size of the light.

Boring for the piles is done in the usual way. The bulbs are then shaped via an underside reamer rotating by a drill rod. Bowls are being used to extract dug-up earth. The reinforcing cage would then be dropped as well as the pile is concreted. The amount of cement as well as the concrete slump should be as suggested in the case of bored cast-in-situ piles.

Also, Read: What Is Crane | 18 Different Types of Cranes

Uses of Under-Reamed Piles

Under-Reamed Piles are commonly used during various soil types, including such sandy soils, clay soils as well as expansive soils. Under-Reamed Piles are supposed to be taken to that depth due to the following factors.

- To prevent adverse effects of seasonal moisture variations in vast soils like black cotton soils.

- To get to the rough strata.

- To achieve a sufficient potential for the forward, downward, lateral loads as well as moments.

- Taking the foundations just below scour mark

- These have been shown to be suitable for factory buildings, including machine foundations.

- Under-Reamed Piles are often used in cases where friction and noise generated by pile construction are minimized.

If the soil filling is not carried out professionally, namely the in such a layer of 20 cm thick with such an optimal moisture content, it is willing to deal. Therefore, in order to take care of the very same, the grade slab was established on a set of Under Reamed Pile spaced around 3 m centre to centre.

Where the grade slab is constructed as a flat slab assisted by Under Reamed Piles, where even the pile cap serves as a column pedestal as with a flat slab, but no beams are given for cost reductions.

This has really performed and seems to be doing so well since ages. This has already been achieved in terminal buildings for Surat and Amritsar International Airports along with several other public buildings.

Advantages of Under-Reamed Piles

- It tends to decrease the vertical settlement as well as the differential settlement.

- It has been used as soil appears to expand and shrink response to fluctuations in moisture or the expansive structure of the soil.

- A requirement of under-reams or bulbs does have the benefit of increasing the ability of bearings and bulbs.

- As the number of bulbs is raised between one and two, the load-carrying capacity of the Under-Reamed Pile is raised.

- A requirement of bulbs is of particular benefit for under-reamed bulbs to prevent uplifting and being used as anchors.

- The cost benefits of the Under-Reamed Piles are due to the smaller depth of the pile pipe, which means that less concrete is used to replace the excavated material.

Also, Read: Tension Vs Compression | What Is Tension & Compression

Disadvantages of Under-Reamed Piles

- In a depth for which components of the soil differ depending on the climatic situation, the under-reamed piles weren’t ideal for waterlogged soil since they seize over by friction.

- This batteries require stringent quality control and constant monitoring during production.

- Much of the period, Under Reamed Piles, are worked manual using a hand-operated pump. It is also very important to protect the plumbing of the pile since because they’re not in the plumbing, the entire load transfer process will shift.

Also, Read: 21 Difference Between Gypsum Plaster and Cement Plaster | What Is Gypsum Plaster | What Is Cement Plaster

Application of Under Reamed Piles

- As black cotton soil have properties that grow as it interacts with moisture or water then contract because it is drying off. There might be a risk of cracking in the system due to this factor.

- In order to prevent disruption caused by a change in soil depth, the reamed pile is being used.

- Often, where the soil base just doesn’t have enough bearing space, it is used under reamed piles to maximize the capacity.

- Underlying reamed piles are appropriate whenever the water level of sandy soil is large.

- It is to be included. Whenever the lifting powers are behaving,

Is Code for Pile Foundation

- Indian Standard IS code 2911 (Part III) – 1980 includes the design and construction of under-reamed piles with one or more bulbs.

- As per the code, the diameter of the bulbs under ream will range from 2 to 3 times the diameter of the stem based on the viability of the construction and design specifications.

- The coding indicates a spacing of 1.25 to 1.5 times the lamp diameter for the lamps.

- The angle of 45 with such a horizontal angle is suggested for all bulbs underneath. This code specifies mathematical expressions for the calculation of bearing and lifting capacities.

Also, Read: WPC Board | Features of WPC Board | Disadvantages of the WPC board | Uses of WPC

What Is Under-Reamed Pile Foundation?

Under reamed piles are bored cast-in-situ concrete piles having one or more number of bulbs formed by enlarging the pile stem. These piles are best suited in soils where considerable ground movements occur due to seasonal variations, filled-up grounds, or in soft soil strata.

Development History of Under-Reamed Pile

Under–Reamed Piles are bored cast-in-situ concrete piles having one or more number of bulbs formed by enlarging the piles stem. The piles are best suited in soils where considerable ground movements occur due to seasonal variation, filled-up grounds, or in soft soil level.

Definition of Under-Reamed Pile

Under reamed piles are bored cast-in-situ concrete piles having one or more number of bulbs formed by enlarging the pile stem. These piles are best suited in soils where considerable ground movements occur due to seasonal variations, filled-up grounds, or in soft soil strata.

Uses of Under-Reamed Piles

The provision of under-reamed bulbs has the advantage of increasing the bearing and uplift capacities. It also provides better anchorage at greater depths. These piles are efficiently used in machine foundations, over bridges, electrical transmission tower foundation sand water tanks.

Also, Read: What Is Fine Aggregate | Types of Fine Aggregates (Classification)

Advantages of Under-Reamed Piles

It decreases the vertical settlement and also differential settlement. It is used when soil tends to swell and shrink due to moisture variation or the expansive nature of the soil. Provision of under-reams or bulbs has the advantage of increasing the bearing and uplift capacities.

Disadvantages of Under-Reamed Piles

- At a depth where the nature of soil varies with a climatic condition, Under–Reamed Piles are not suitable for waterlogged soil, as they take load by friction.

- These piles need strict quality control and regular supervision during construction.

Features and Details of Under Reamed Piles

Under–Reamed Piles are bored cast-in-situ concrete piles having one or more number of bulbs formed by enlarging the piles stem. The piles are best suited in soils where considerable ground movements occur due to seasonal variation, filled-up grounds, or in soft soil level.

Increasing Load-Carrying Capacity of Under Reamed Piles

The ultimate load-bearing capacities of piles are maximum when the spacing between two reamed bulbs is 2.5 times the diameter of the under-reamed bulb. It appears that the spacing between two under-reamed bulbs suggested in (1.25 to 1.5 times) IS 2911(1980) is not the optimum, 5.

Also, Read: What is Plum Concrete | Application | Mix Design | Methodology

Application of Under Reamed Piles

The provision of under-reamed bulbs has the advantage of increasing the bearing and uplift capacities. It also provides better anchorage at greater depths. These piles are efficiently used in machine foundations, over bridges, electrical transmission tower foundation sand water tanks.

Is Code for Pile Foundation

Following are the Indian Standard Codes on Pile Foundations: IS 2911 : Part 1 : Sec 1 : 1979 Driven cast-in-situ concrete piles. IS 2911 : Part 1 : Sec 2 : 1979 Bored cast-in-situ piles. IS 2911: Part 1 : Sec 3 : 1979 Driven precast concrete pile.

Under Reamed Pile Design Example

Under reamed piles are bored cast-in-situ concrete piles having one or more bulbs formed by enlarging the pile stem. These piles are best suited in soils where considerable ground movements occur due to seasonal variations, filled-up grounds, or in soft soil strata.

Under-Reamed Pile Foundation Design

Under-reamed pile foundations are a type of deep foundation system commonly used to support structures on soft and compressible soils. These foundations are designed to increase the bearing capacity of the soil by creating bulb-shaped enlargements, called under-reams, at the base of the piles. The under-reams provide additional resistance against uplift and lateral loads.

Here are the general steps involved in the design of under-reamed pile foundations:

- Site investigation: Conduct a thorough geotechnical investigation of the site to determine the soil properties, including its bearing capacity, compressibility, and groundwater conditions. This information is crucial for designing the pile foundation.

- Load analysis: Determine the loads that the foundation needs to support, including dead loads, live loads, and any additional imposed loads. Consider both vertical and horizontal loads acting on the structure.

- Pile layout: Determine the spacing and arrangement of the piles based on the loads, soil conditions, and structural requirements. The number and diameter of piles are typically determined based on the structural loadings.

- Under-ream design: Determine the dimensions and shape of the under-reams. The under-ream diameter is usually larger than the pile shaft diameter, and its depth is typically determined based on the design requirements and soil conditions.

Under-Reamed Pile Foundation Construction Process

The construction process for under-reamed pile foundations typically involves the following steps:

- Excavation: Excavate the site to the required depth for the pile foundation. The depth is determined based on the design requirements and the soil conditions. The excavation can be done using various methods such as drilling or augering.

- Under-ream formation: Once the excavation is complete, create the under-reams at the base of the pile. Under-reams are bulb-shaped enlargements that provide additional bearing capacity. This is typically done using under-reaming tools or specially designed drill bits. The diameter and depth of the under-reams are determined based on the design specifications.

- Reinforcement placement: Install the reinforcement cages or bars into the under-reams and along the pile shaft. The reinforcement provides tensile strength to the pile and helps resist bending moments and shear forces. The reinforcement should be positioned as per the design requirements and should be adequately spaced and tied together.

- Concrete pouring: Pour concrete into the excavated holes, ensuring that it fills the under-reams and encases the reinforcement. The concrete mix should be appropriate for the project specifications and should be placed using proper techniques to minimize segregation and ensure good quality.

Benefits of Under-Reamed Pile Foundations

Uses of Under-Reamed Piles

- To avoid the undesirable effect of seasonal moisture changes in expansive soils such as black cotton soils.

- To reach hard strata.

- To obtain adequate capacity for downward, upward, lateral loads and moments.

- To take the foundations below the scour level.

Under-Reamed Pile Foundation Cost Estimate

The cost estimate for under-reamed pile foundations can vary depending on several factors, including project-specific requirements, local labor and material costs, site conditions, and the size and complexity of the structure.

Under-Reamed Pile Foundation Design Guidelines

When designing under-reamed pile foundations, it is important to follow certain guidelines to ensure the stability, load-bearing capacity, and structural integrity of the foundation system. Here are some general design guidelines for under-reamed pile foundations:

- Geotechnical investigation: Conduct a comprehensive geotechnical investigation to characterize the soil properties, including strength, compressibility, and groundwater conditions. This information is crucial for determining the appropriate design parameters and under-ream dimensions.

- Load analysis: Determine the loads that the foundation needs to support, including dead loads, live loads, and any additional imposed loads. Consider both vertical and horizontal loads acting on the structure.

- Pile spacing and arrangement: Determine the spacing and arrangement of the piles based on the loads, soil conditions, and structural requirements. The number and diameter of piles are typically determined based on the structural loadings.

Under Reamed Pile Foundation

Under-reamed pile foundations are a type of deep foundation system that is commonly used to support structures on soft and compressible soils. These foundations are designed to increase the bearing capacity of the soil by creating bulb-shaped enlargements, called under-reams, at the base of the piles. The under-reams provide additional resistance against uplift and lateral loads.

Under Reamed Piles Are Generally

Under reamed piles are bored cast-in-situ concrete piles having one or more number of bulbs formed by enlarging the pile stem. These piles are best suited in soils where considerable ground movements occur due to seasonal variations, filled up grounds or in soft soil strata.

What Is Under Reamed Pile Foundation?

A cast-in-situ concrete pile with an enlarged bulb at bottom made by either cutting or scooping out soil or by any other suitable process is called Under-Reamed Pile. Under-Reamed Piles are also called bored cast-in-situ concrete piles.

What Type of Method of Installation Can Be Used for the Under Reamed Piles?

Under-Reamed Piles are bored cast-in-situ concrete piles having one or more number of bulbs formed by enlarging the piles stem. The piles are best suited in soils where considerable ground movements occur due to seasonal variation, filled up grounds or in soft soil level.

What Is Bulb in Pile Foundation?

The bottom end of the pile has a spherical enlarged portion called an under rim or bulb. The diameter of the pile is 20 cm to 50 cm and the diameter of the bulb is 2 to 3 times the diameter of the pile. Under reamed Pile lengths range from 3 m to 8 m.

What Is Pile Foundation?

Pile foundations are long, thin elements generally made of steel or reinforced concrete. They transfer the load through weak, compressible material onto more compact, less compressible stiffer soil or rock at greater depth.

Types of Pile Foundation

There are a four main types of pile foundation, each with its own method of construction:

- Driven piles.

- Bored piles.

- Driven and cast-in-situ piles.

- Aggregate piles.

Caisson Pile Construction Method

Caisson construction is a foundation used in deep water or soft soil. It involves a series of large, watertight cylinders that are sunk into the ground and filled with concrete. The base provides a stable foundation for structures built on top of it. Bridges, docks, and large structures often use caisson construction.

Like this post? Share it with your friends!

Suggested Read –

- What is a Pile Cap

- Top 10 Cement Companies in USA

- Top 15+ Best Plywood Brands in India

- Top 10 Best Cement Companies In India 2021

- Top 10 Bathroom Fittings & Sanitary Brands India

- What Is Grouting | Types of Grouting | Advantage of Grouting

- What Does Parapet Mean | Types of Parapet Wall | Uses of Parapet Wall

- Cinder Block Vs Concrete Block | What Is Cinder Blocks | What Is Concrete Blocks

- Monolithic Definition | Monolithic Footing | Monolithic Slab Foundation | Advantages & Disadvantages of Monolithic Slab Foundation | Monolithic Slab

Originally posted 2023-06-15 15:55:47.

Leave a Reply