What Is Drop Manhole Mean?

Important Point

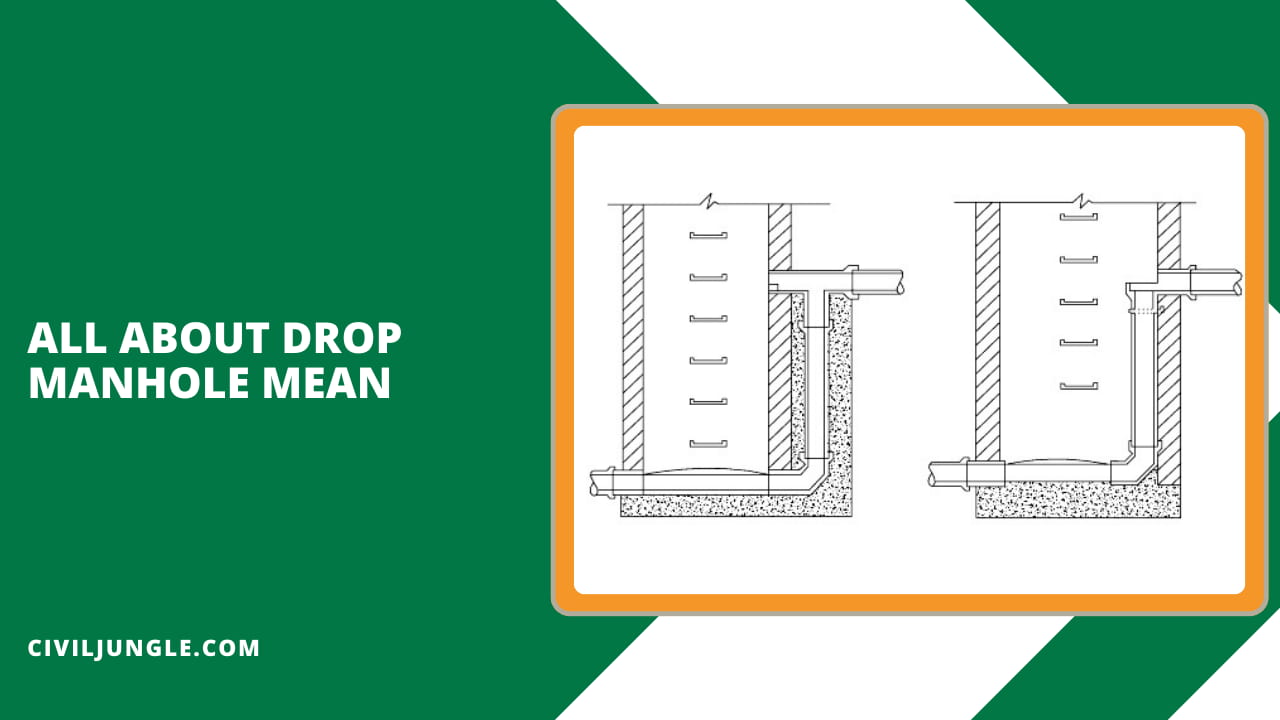

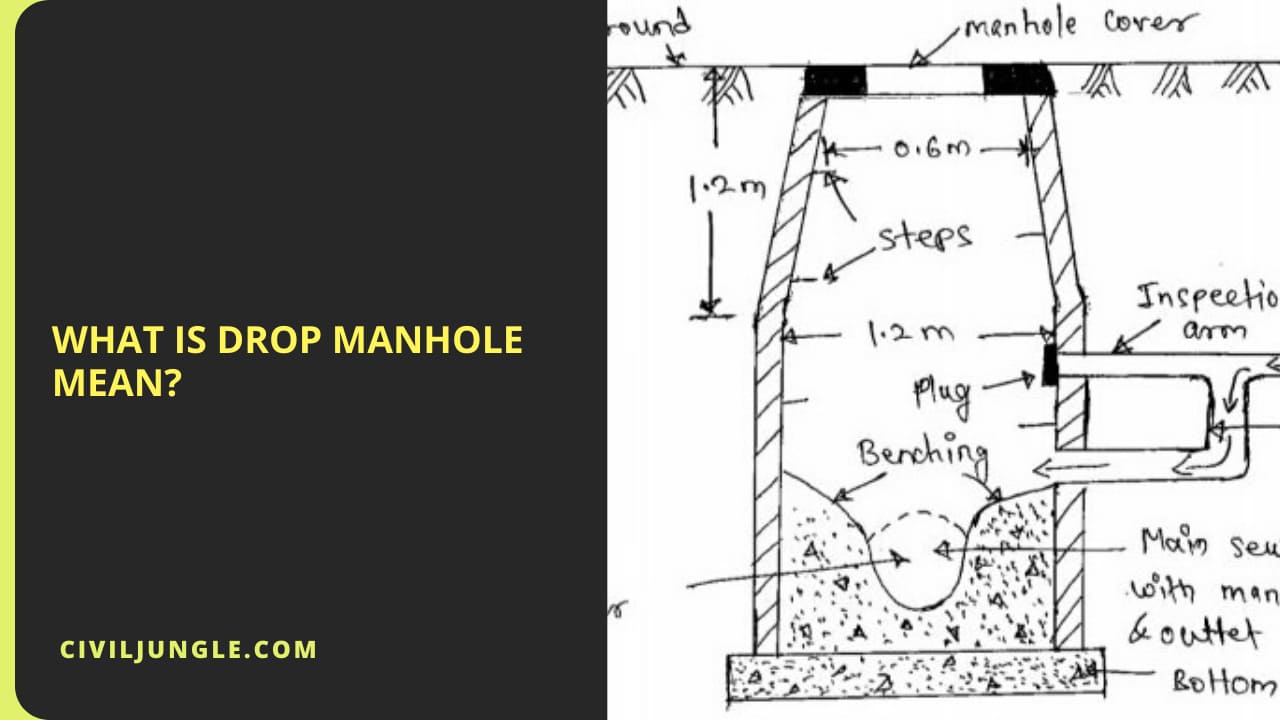

Drop manhole is a type of manhole where the vertical pipe is permitted to flow between the main sewer and branch sewer. This type of manhole is used in steep areas or where the elevation of the inlet pipe is more than the elevation of the outlet pipe.

In drop manhole, the stop invert is at the level from the invert of the outlet. Drop manholes have a larger sloping gradient, that’s why this type of manhole construction is uneconomical.

The main sewer flow is routed outside of the manhole. The pipe which passes through the manhole barrel is called inside the drop, and that in the exterior portion is termed as an outside drop. These outside drops are for routine checking, inspection and cleaning purpose.

Also, Read: What Is Cross Drainage Work | Types of Cross Drainage Works | Syphon Aqueduct

Manhole Construction

There are several processes and different steps available for manhole construction. Those steps are

- Excavation

- Bed Concrete

- Brick Masonry

- Plaster and Pointing.

- Channel and Benching

- Footrests

- Manhole Covers and Frames

Step 1 – Excavation:

This is the first step of manhole construction. The excavation process is done as per the manhole’s dimension and depth mentioned in the plan and the drawing.

You must include the excavation width for some free space for workers to work that place freely.

Step 2 – Bed Concrete:

The second part of constructing a manhole is this. Here a paste of concrete of ratio 1:4:8 is laid down the manhole bed or constructed.

Minimum bed concrete thickness should be 20 cm to 30 cm for the manhole depth of 4.25 m to above 4.25 m. Where there is a presence of loose soil, then you need to construct a special foundation.

Useful Article for You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is Mdf Mean

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Sand Blasting

- What Is a Span Bridge

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- Different Types of Beam

- What Is Pedestal

- What Is Plumbing Fixtures

- What Is Slab Construction

- What Is Calacatta Quartz

- What Is Auxiliary View

- Sheepsfoot Roller

- What Is 1 Flight of Stairs

- Pier in Construction

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- Arch Foundation

- What Is a Stair Landing

- What Is Stone Masonry

- What Is a Spandrel Beam

- What Is Pier and Beam Foundation

- What Is a Pile Cap

- What Is a Mat Foundation

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is Modulus of Rupture

- What Is a Flush Door

- What Is Residential Construction

- What Is the Best Foundation for a House

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is a Monolithic Slab Foundation

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is a Tremie

- What Is Tributary Area

- What Is Shoring Construction

- What Is a Cason

- What Is Wall Putty

- What Is the Difference Between Mortar and Concrete

- What Is Bhk

- What Is Sbc of Soil

- What Is Plinth Level

- What Is Water Proofing

- What Is Mix Design of Concrete

- What Is Fine Aggregate

- What Is Retention Money

- What Is Design Mix

- What Is Isometric Scale

- What Is Development Length

- What Is Superelevation

- What Is Wall Made Of

- What Is Micro Piling

- What Is Soil Stack

- What Is a Half Wall Called

- What Is Flagstone

- What Is a Cinder Block

- What Is Floors

- What Is a Parapet in Construction

- What Is Concept Drawing

- What Is a 30 Degree Angle

- What Is a Mezzanine Level

- What Is Plinth Area

- What Is Precipitation

- What Is a Soffit

- What Is the Difference Between Residual and Transported Soil

- What Is a Drop Manhole

- What Is Oblique View

- What Is a Flyover Bridge

- What Is Tie Beam

- What Is the Cost of 1 Bag Cement

- What Is Well Foundation

- What Is the Principle of Chain Surveying

- What Is Dlc in Road Construction

Step 3 – Brick Masonry:

To construct a manhole regular bricks of strength 7.5N are required and mortar of 1:4 ratio used. For arched type structural manhole 1:3 ratio cement mortar is used.

The wall thickness of 5 inch is limited to 4.25 m depth of manhole, and 10inch wall is provided where the depth of manhole is more than 4.2m.

The outer part of manhole should be smooth, and the masonry pipe should be specially treated and leak proof.

Step 4 – Plaster and Pointing:

This is one of the most important steps of manhole constructing. The Master of manhole should be 12 mm thick, and it requires 1:3 cement mortar paste.

For archer type of structure, the plaster requires to the crown portion of the manhole, and it requires 1:2 cement mortar paste.

We don’t need to plaster outside, but in case of saturated soil, 12mm thick plaster required and inner part of the manhole should be waterproof with a waterproofing agent.

Step 5 – Channel and Benching

Benching in the manhole is a path constructed by cement mortar which converts the wastewater in a certain direction and helps the interior part of the manhole from getting damaged.

The channel and benching of the manhole are constructed by the cement concrete ratio of 1:2:4, the channel and benching must be neatly finished.

The depth of the channel and benching list is given below-

|

Sizes of Drain in mm |

Top of Channel at the Centre Above Bed Concrete in Cm |

Depth of Benching at Side Wall Above Bed Concrete in Cm |

|

100 |

15 |

20 |

|

150 |

20 |

30 |

|

200 |

25 |

35 |

|

250 |

30 |

40 |

|

300 |

35 |

45 |

|

350 |

40 |

50 |

|

400 |

45 |

55 |

|

450 |

50 |

60 |

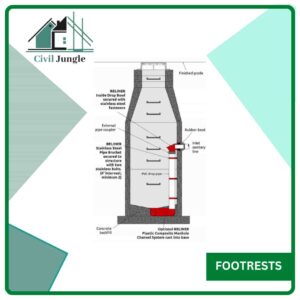

Step 6 – Footrests

It is provided for easy access for cleaning and maintenance. If the depth of manhole is more than 0.8 m, then footrests are provided. It is made of either mild steel or PVC.

Footrests are rooted in 200 mm deep in a 200 x 200 x 100 mm concrete block. The first footrest must be 450 mm from the manhole cover.

Step 7 – Manhole Covers and Frames

The manhole covers must be airtight and watertight. The manhole covers and frames are following types-

|

Grade |

Grade Designation |

Type / Shape of Cover |

| Light Duty | LD-2.5 | Rectangular, Square, Circular |

| Medium Duty | MD-10 | Rectangular, Circular |

| Heavy Duty | HD-20 | Circular, Square, Rectangular |

| Extra Heavy Duty | EHD-35 | Circular, Square, Rectangular |

Also, Read: Basic Plumbing System | Drainage System | Supply and Drainage Subsystems

Types of Manholes:

The manhole types are mainly classified into two categories-

- Based on Depth

- Based on Construction Material

#1. Based On Depth:

Based on depth, the manholes are classified into another three categories-

- Shallow Manholes:

- Normal Manholes:

- Deep Manholes:

#a. Shallow Manholes:

The manholes with a depth of 0.75m to 0.9m is called shallow manhole. Shallow manholes are constructed where low traffic, this type of manholes are mainly rectangular type.

Shallow manholes are also referred to as inspection chamber.

#b. Normal Manholes:

Those manholes whose depth are greater than 0.75 m but not more than 2 m is called normal manhole. This manholes are covered with thick cover and square in shape.

#c. Deep Manholes:

Deep manholes are that type of manhole which depth is more than 2m. This types of manholes are mainly circular in shape.

Also, Read: What Is Sunken Slab | Advantages & Disadvantages Sunken Slab

#2. Based On Construction Material:

Depending on the construction material manholes are classified into three categories, those are following-

- Precast Concrete Manhole:

- Plastic Manhole:

- Fibreglass Manholes:

#a. Precast Concrete Manhole:

This type of manholes are constructed by precast concrete, and it’s a traditional type manhole. In this type, the manhole components are directly placed in the site. This type of manhole has a huge use in all over the world.

#b. Plastic Manhole:

Plastic manholes are made of polyethene material, and it does not harm the environment. Plastic manholes do not require too much maintenance, and it’s highly resistive against corrosion.

#c. Fibreglass Manholes:

Fibreglass technology is used to construct this type of manhole. This type of manhole is lightweight and easy to install; that’s why it’s economical to use. Fibreglass manholes are durable and eco-friendly.

Also, Read: What Is Soil Vent Pipe | How Does Soil Stack Pipe Works | Soil Vent Pipe Material | Types of Plumbing System

Useful Article for You

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Cmu Wall Meaning

- Gradient Road

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- Well Points

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

- How Heavy Is Dirt

- Tender Meaning in Architecture

- Dark Olive Green House

- Cast in Place Concrete

- Lean to Roof

- How Tall Is an Average Door

- Grade Beam Foundation

- Window Sill Height

- Horizontal Alignment Definition

- Concrete Cold Joint

- Types of Traps

- Types of Pipe

- Wood Supporting Beams

- Finishing Plaster

- Home Depot Scrap Wood

- Lvl Beam Size Calculator

- Structural Shell

- Curb Types

- Msand

- Optimum Dry Meaning

- Disadvantages of Low-E Glass

- Bridge Abutment Definition

- Build Materials List

- Composite Masonry Wall

- Is Cedar a Hardwood or Softwood

- Modified Proctor Test

- Physical Properties of Sand

- Crane Machine Construction

- Types of Gable Roofs

- Door Frame Types

- How Much Does 55 Gallons of Oil Weigh

- Dog Leg Stairs

- Concrete Salt Finish

- Westpoint Bridge Builders

- Types of Porches

- Hempcrete Disadvantages

- Roof Pitch Types

- Types of Weirs

- Asphalt Floor

- Dutch Roof

- #6 Rebar Weight Per Foot

- Prizmatic Compass

- Bond Break Concrete

- Poured Concrete Wall Cost Calculator

- How Many 60 Lb Bags of Concrete in a Yard

- Wood Fence Post Spacing Chart

- Falsework

- Design of Building Structures

- Topping Slab

- Types of Cinder Blocks

- Fresh Concrete

- Door Colors for Red Brick House

- Clear Cover Concrete

- Tiles Brand

- Cement Consumption in Plaster

- Aggregate Density Kg M3

- Weight of Concrete Slab Calculator

- Is Clay Smaller Than Silt

- How to Calculate Dead Load

- Bad Concrete Work

- Stepped Foundations

- Residential Construction Cost Estimator Excel

- Different Construction Trucks

- Septic Pump Replacement Cost

- Dead Load Calculator

- Beam Vs Column

- Concrete Mix Ratio

- Caisson Foundation

- Glulam Beam Weight Calculator

- Bituminous Pavement

- M30 Mix Ratio

- Is 2502

- Reinforced Brick Work

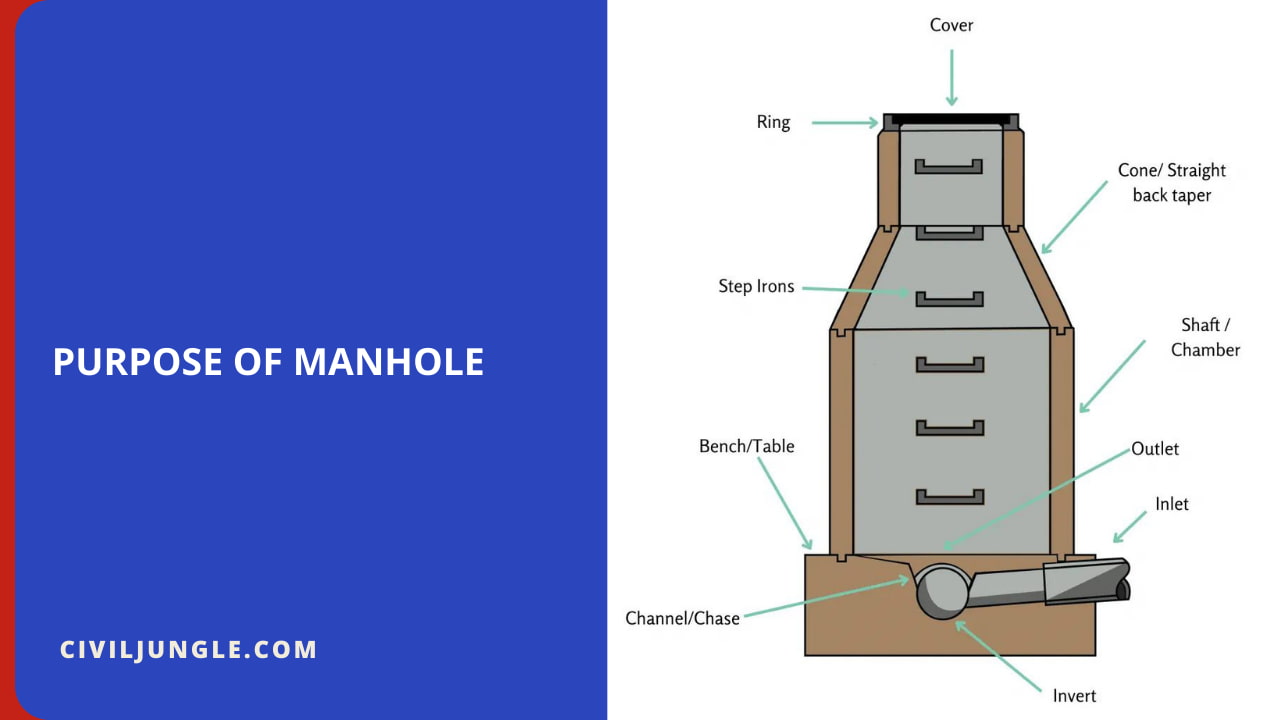

Purpose of Manhole

- There are various purposes of manhole; the first one is for cleaning, repair and maintenance of the sewage system.

- Manhole allows the change of alignment and direction of sewage.

- Some manholes are constructed with perforated covers; it helps to release the foul gases, so it allows the ventilation of the sewage system.

- Sewer lines are laid in a convenient length with support of manhole.

Also, Read: What Is Plumbing Joint | Types of Plumber Joint | Different Types of Pipe Joints and Where Are Use

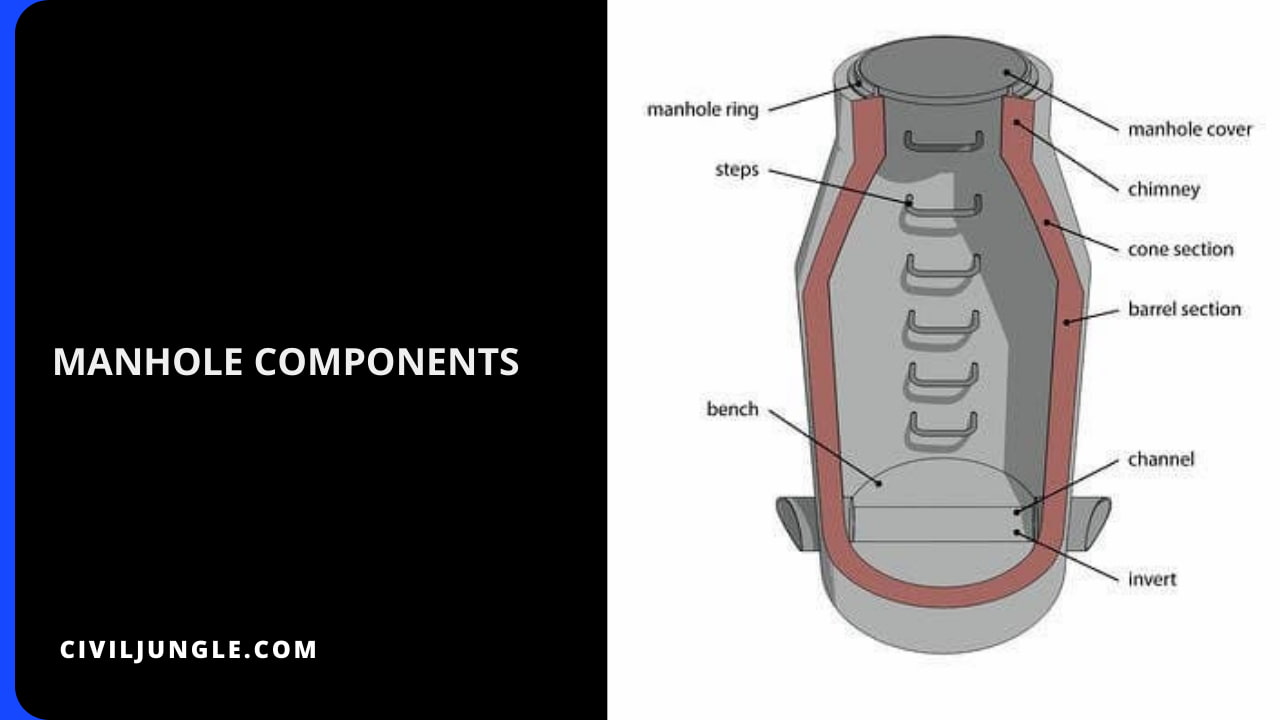

Manhole Components

There are mainly six types of components are present in a manhole. Those are-

- Access Shaft.

- Working Chamber.

- Base and Sidewalls.

- Bottom or Invert.

- Steps or Ladder.

- Cover and Frame.

#1. Access Shaft:

- Access shaft is the upper portion of a deep manhole. It’s a vertical passage which gives access to the working chamber from the manhole cover.

- The minimum size of the rectangular access shaft is 0.75 m x 0.6 m and 0.7 m dia for a circular manhole.

- Sometimes access shaft is covered with reinforced concrete. In circular manhole, the access shaft is made little inward slope.

#2. Working Chamber:

- The lower portion of the manhole is termed the working chamber. This is provided for cleaning and inspection chamber.

- The minimum size of the working chamber for rectangular manhole is 1.2 m x 0.9 m. For circular type manhole, the dia of the working chamber is 1.2 m.

#3. Base and Sidewalls:

- The base of the manhole is generally made of plain cement concrete, and it resists the entry of groundwater. 15 cm is the minimum thickness of concrete bed for the depth of 0.8 m manhole.

- The sidewalls are made of brick masonry, stone masonry or reinforced concrete cement.

- The minimum thickness of the brick sidewall is 20 cm for the depth of 1.5 m and 30 cm for the depth of more than 1.5 m. Now, we use a rule to calculate the thickness of the brick wall, that is-

t = 10 + 4d

Where,

t = thickness of the wall in cm

d = depth of manhole in m

#4. Bottom or Invert:

- The bottom part of the manhole is like semicircular or U-shaped and made of PCC.

- The side of this is perfectly vertical. The slope provided for benching is 1 in 10 to 1 in 6.

- The invert chamber is constructed to prevent the backflow the sewage flow.

#5. Steps or Ladder:

- This is provided where the depth of manhole is more than 0.8 m. Steps are made of cast iron, and it’s horizontal centre to centre distance is 38 cm, and vertical is 30 cm.

- Topside is placed 45 cm from the cover of a manhole. Ladders are generally provided in deep manholes.

#6. Cover and Frame:

- The cover set is provided at the top of the manhole. Generally, the covers of manholes are circular in shape, and the diameter is 56 cm, and depth is 0.9 m.

- Covers are made of cast iron. The dimension of this is 20 to 25 I’m height and 10 to 12 cm base. The weight of the cover and frames is between 90 kg to 270 kg.

Also, Read: 20 Types of Plumbing Pipes for Different Use

Define Appurtenances:

- In Civil Engineering appurtenances means sewer appurtenances.

- Sewer appurtenances are such type of structure constructed in a sewerage system in a reasonable interval.

- This includes manhole, clean out, lamp hole, catch basin, etc.

Appurtenances Examples:

There are several examples of appurtenances, those are-

- Manholes:

- Lamp Holes:

- Cleanouts:

- Catch Basins:

- Inverted Siphons:

- Storm Regulators:

- Flushing Tank:

- Gullies:

#1. Manholes:

- Manholes are generally made of reinforces cement concrete.

- It’s provided in suitable interval along the sewer line for cleaning, maintenance and inspection purpose.

#2. Lamp Holes:

- This is a small opening constructed along with sewer line to permit the lamp when the maintenance is running to clear the darkness.

#3. Cleanouts:

- The cleanout is an inclined pipe which is started from the ground and connect the ground sewer.

- It is generally provided in the upper sewer instead of a manhole.

#4. Catch Basins:

#5. Inverted Siphons:

- It’s a passage which dropped below the hydraulic gradient line beneath the valley, road, railway, stream etc.

- It’s also known as a depressed sewer.

#6. Storm Regulators:

- It’s constructed to divert the excess stormwater into another stream.

#7. Flushing Tank:

- This is that type of tank which holds water, and by flushing, it cleans the dead-end of the sewer.

#8. Gullies:

- These opening are constructed in the road to divert the stormwater into the groundwater sewer.

Sewer Appurtenances

Sewer appurtenances are the various accessories on the sewerage system and are necessary for the efficient operation of the system. They include manholes, lamp holes, street inlets, catch basins, inverted siphons, and so on.

What Does Drop Manhole Mean

A mainline or house service line lateral entering a manhole at a higher elevation than the main flow line or channel. If the flow is routed down through the manhole barrel, the pipe down to the manhole channel is called an inside drop.

Types of Manholes

Manholes typically fall into one of three categories, which are shallow, normal, and deep. The type of manhole chosen for a specific area depends on both the size of the sewer or stormwater line as well as the manhole function. Manholes typically fall into one of three categories, which are shallow, normal, and deep.

Also, Read: What are Traps | What Does Trap do | 12 Types of Traps In Plumbing

Purpose of Manhole

Manhole is built with the lateral, branch, main, trunk, and interceptor sewer lines for the purpose of allowing access to the sewer lines by people and equipment for maintenance and repair functions. They are the round metal lids that you see mostly in streets

Drop Manhole

A drop manhole is a manhole in which a vertical pipe is provided to allow for flow between the branch sewer and the main sewer. It is utilized in areas where the slope is steep or when an inlet pipe’s invert elevation is much higher than the outlet pipe’s invert level.

Also, Read: What Is Septic Tank | How Does A Septic Tank Work | Septic Tank Design based Per User Consumption

Appurtenances Examples

More examples of appurtenances include in-ground swimming pools, a fence, or a shed that are all fixed to the land. The term can also be used to describe the acreage behind a home. This plot of land, or the backyard, is generally viewed as being part of the property an appurtenance of the house.

Like this post? Share it with your friends!

Suggested Read –

- Anatomy of Stairs

- Dead Load Example

- Different Types of Washers | When to Use Washers | How to Use a Washers | Shapes of Washers

- What Is Survey Levelling | Important Terms Related to Levelling | What Are Different Types of Levelling | Types of Trigonometric levelling

- Emulsion Paint Vs Oil Based Paint | Purpose of Providing Paints | Properties of Good Paint | Properties of Good Paint | What Is Oil Based Paint

- Building Layout | How to Building Layout | What Is Method of Layout of Building | Control Lines of Construction | Construction Layout

- Definition of Shear Force and Bending Moment | What Is Shear Force | What Is Bending Moment | Relation Between Loading, Shear Force & Bending Moment

- What Is Road Pattern | Different Types of Road Patterns | Grid Pattern Definition | Radial Pattern | Rectangular or Block Pattern | Minimum Travel Pattern

Leave a Reply